Axial Flow (Non-Slam) Check Valves.

The Axial Flow Non-Slam Nozzle Check Design is a significant step in innovation regarding check valves. The primary differentiation is their sizing and selection, tailoring the individual valve for the application’s process parameters. This philosophy differs significantly from the standard norm of selecting check valves based on their pipe size. Driven by the industry requirement to ensure surge mitigation, axial flow check valves are an unmatched check valve solution.

There have been many developments driven by operation demands through the evolution of axial flow check valves themselves.

Features

NOREVA nozzle check valves are used in applications where the reverse flow of a liquid or gaseous fluid must be avoided. They offer non-slam closing and are energy-saving due to low pressure loss and maintenance-free performance. They are specifically sized for the application to prevent excessive pressure drops and to mitigate surge conditions.

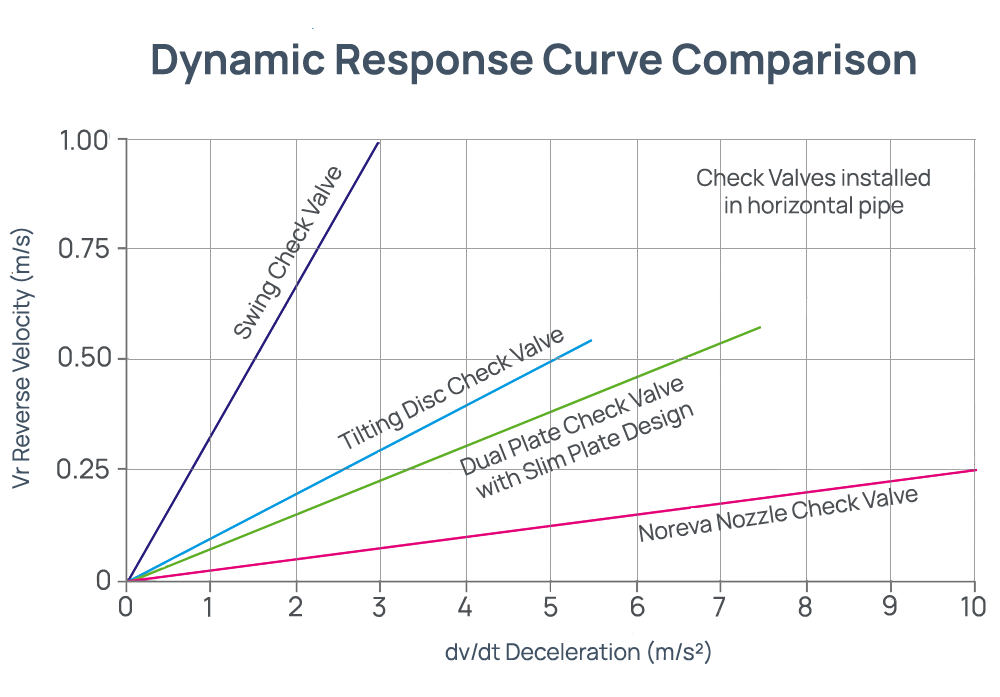

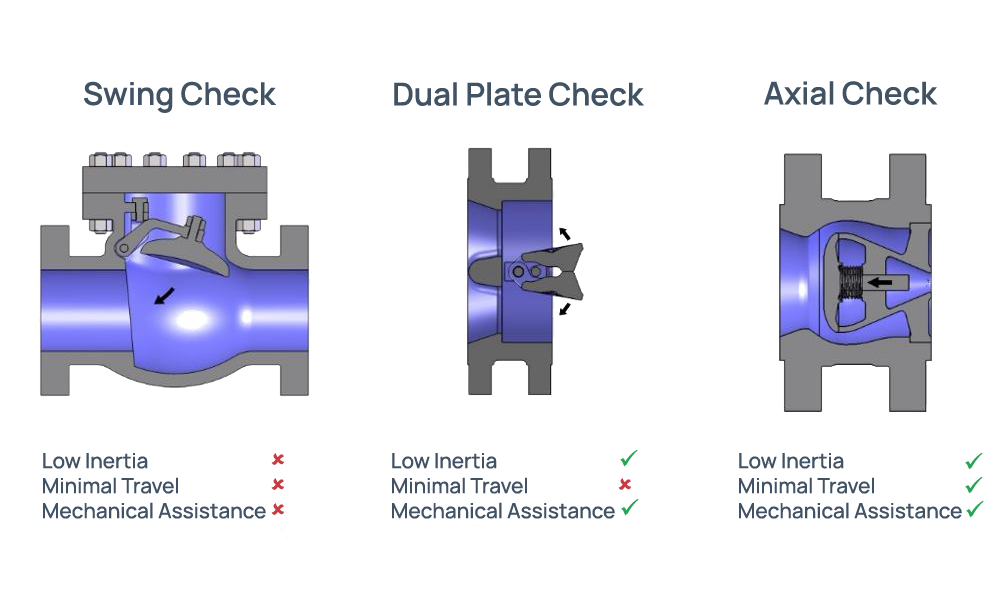

When closing a valve against a rapidly moving body of fluid, pressure pulses occur, commonly referred to as surges or water-hammers. In relation to the valve, the term “slam” is the root cause of the surge/pressure wave phenomenon. Valve slam usually occurs after a pump trip when the forward flow decelerates, reverses, and accelerates back towards the pump. The check valve must close quickly before the reverse velocity is too high to minimize the surge pressure. The disc of the valve must have low friction, short travel for quick response, and springs to assist with the disc’s closure to reduce slam. The chart below shows the differences in the dynamic response of different types of check valves. As established, by meeting these requirements, NOREVA provides a range of non-slam check valves to meet the most stringent requirements and has the best dynamic response compared to conventional swing check or dual plate check valves.

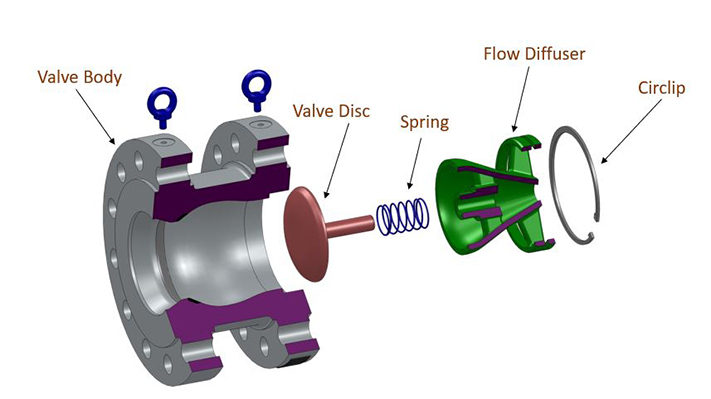

Available in sizes 1” through to 10”, the NOREVA type Z valve is a solid disc and shaft type. The axial design allows for a streamlined flow path around the disc and high-pressure recovery, minimizing the pressure drop across the valve. A short-stroke length provides the quick response required by a non-slam check valve.

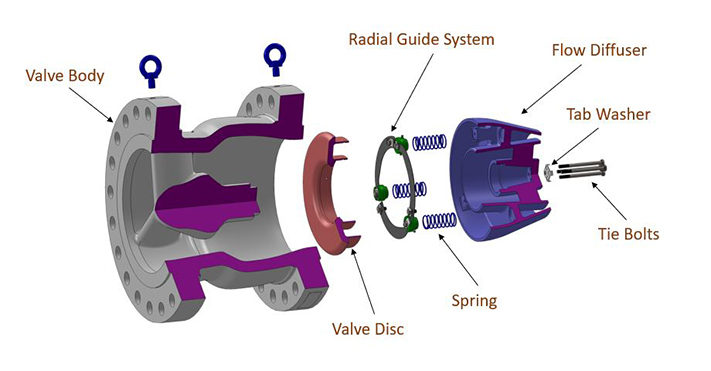

The Ring Disc design, Type N valve, in sizes 12” and above ensures that the disc remains light and responsive even in large sizes. When mounted on multiple helical springs and radial guide assembly (type NB/NK) or a shaft with a single, centrally mounted spring (type NZ, NC), the disc moves freely without any of the frictional forces associated with the solid disc and shaft design.

With the flow path both around and through the disc’s center, the valve’s flow capacity is best in class. Due to the diffuser’s excellent pressure recovery properties, the minimal pressure drop across the valve gives lifetime energy savings compared to a more conventional check valve design.

NOREVA type NZ and NC valves are specially designed for gas applications as they have a centrally guided, single spring with very low fully open velocity. The difference between NZ and NC series compared to other Ring Disc Valves is the center of gravity of the disc. In NZ and NC series, the center of gravity is over the center of the surface it is sliding on. Due to this design change, a softer spring, which functions at very low flow rates, can be used to eliminate the moving component’s tilting effect.