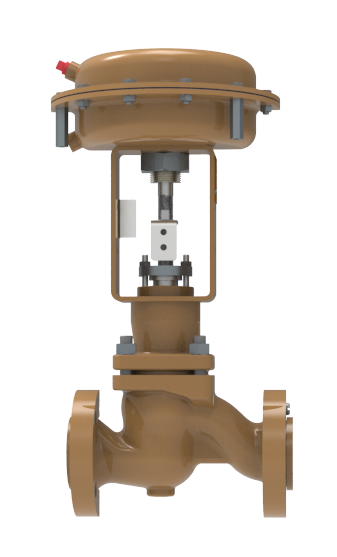

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST. Model 989 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in flanged.

Additional information

| Valve Size | ¾”, 1”, 1-½”, 2” |

|---|---|

| Maximum CV | 0.25 to 50 |

| Materials | Body – CS, 316L SST, NI-Mo-Cr, CW- 12MW |

| End Connections | Separable flanges for Classes 150#, 300#, flanges in ASME or DIN |

| Temperature Range | -20°F to +750°F (-28.8°C to +398°C) |

| Pressure Drop | TFE seat- up to 1480 psid (102 bard) |

| Face-to face | ISA – 75.08.01 (short) |

Features & Benefits:

- High-grade trim components that can withstand corrosive chemicals (316L SST) and are rated for NACE service

- Flow-to-open (flow under) design increases rangeability and stability

- Trim can be stellated in metal seated design for flashing or partial cavitating liquid services

- Available in standard and internal/external live-loaded V-ring packing designs. As well as Non-live loaded Jammed option

- Recommended for flashing or partial cavitating liquid services or where extended time periods of On/Off or Low-flow (<10% open) operation occur and good shut-off is required

- CRN number is available

Manual

| 988-989 IOM |

988-989 IOM |