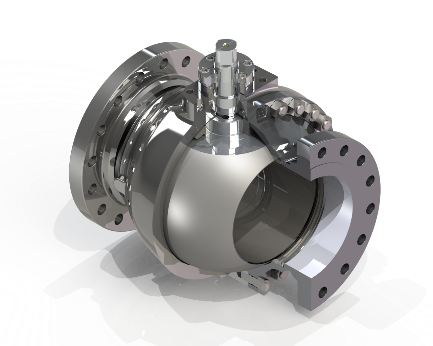

Argus FK76M trunnion mounted ball valves are engineered to deliver long-lasting, tight shut-off performance in oil and gas, petrochemical and chemical industry applications. It features a modular design that allows simplified adaptation to diverse safety, emissions and performance requirements. The FK76M ball valve is available in standard and severe service designs and offers metal-seated and soft-seated configurations for reliable sealing performance. Special and customized designs are also available for ultimate high cycle, high temperature and similar challenging applications. These valves are designed to meet API 6D and ASME B16.34 requirements (API 608 on request). Fugitive emission to ISO 15848 (API 641 on request). Fire-safe to API 607 or ISO 10497.

Additional information

| Valve Size | 3" to 36" |

|---|---|

| Pressure Class Standard | ASME B16.34 |

| Pressure Class Range | Class 150 to Class 900 |

| Body | Two Piece, Split Body/Three Piece |

| End Connections | Flanged ASME B16.10 |

| Face-to-Face Standard | ASME B16.10 |

| Bonnet | Standard, ISO 15848-1, High Temperature |

| Packing | PTFE/Graphite |

| Seat Type | Metal-to-Metal & Soft |

| Shut-Off Classification | ANSI FCI 70-2 Class V, VI |

Features & Benefits

- Improved plant and personnel safety from valve design, which meets fugitive emissions standard ISO 15848

- Scalloped Seat design to prevent solids and particulate from building in the seat pocket

- Special bearing configurations, including cladding of critical areas and trim coating configurations, improve valve life-time

- Stem supported in bearings to ensure seals are free from operation loads

- Designed for temperatures up to +1022°F for the highest demands on valve tightness in process and to atmosphere (FE)

- Chambered ball seats, seat pocket body design, stem seal protection and flushing system designs support valve performance and extend service life-time

- Process optimized coatings, cladding option and wearing protection feature for extended ball valve life-time

- Flushing options in critical valve areas (e.g., on seats, stem or cavity) avoid media build up to improve service life-time

- High performance designs for high pressure, metal to metal seat gas tightness solutions in oxygen service

Standards & Certifications

| Certifications | Canadian Registration Number (CRN) |

|---|---|

| PED Directive 97/23/EC | |

| Fire-Safe to API 607, ISO 10497 | |

| Anti-Static to DIN EN ISO 17292 | |

| Design Standards | API 6D – Specification for Pipeline and Piping Valves |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.10 – Face to Face & End Dimensions of Valves | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding End | |

| ASME SA Materials | |

| ASTM A Materials | |

| Quality | IS0 9001:2008 |

| ATEX QAN | |

| IECEX QAR |