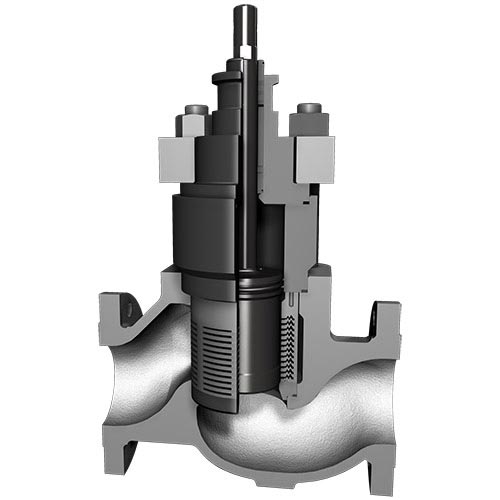

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services.

Additional information

| Function | Gaseous Noise Reduction |

|---|---|

| Pressure Stages | 2 to 8 |

| Cv Range | 4 to 4000 |

| Noise Attenuation | 30 dBa |

| Trim Design | Stacked Discs |

| Solids Capable | No |

| Materials | Alloy |

| Base Valve | Flowserve Valtek Mark Series |

| Valve Size | 1-1/2" to 36" |

| Pressure Class Standard | ASME B16.34 |

| Pressure Class Range | Class 150, 300, 600, 900, 1500, 2500, 4500 |

Features & Benefits

- Noise attenuation of up to 30 dBa

- TigerTooth design employs highly engineered concentric grooves (or teeth) machined into the face and backside of a series of circular stacked discs

- Legs separate one disc from another, providing a gap between individual discs, forming flow passages

- TigerTooth trim has the sudden expansion and contraction phenomenon that takes place as the flow passes over the teeth

- The TigerTooth valve's ability to gradually reduce pressure without generating high velocities is important for the reduction of noise

- In addition to the standard linear and bi-linear designs, Tiger-Tooth can also be designed with a full-open area at the top of the stack to provide additional flow capacity

- Passages in the TigerTooth design are self cleaning