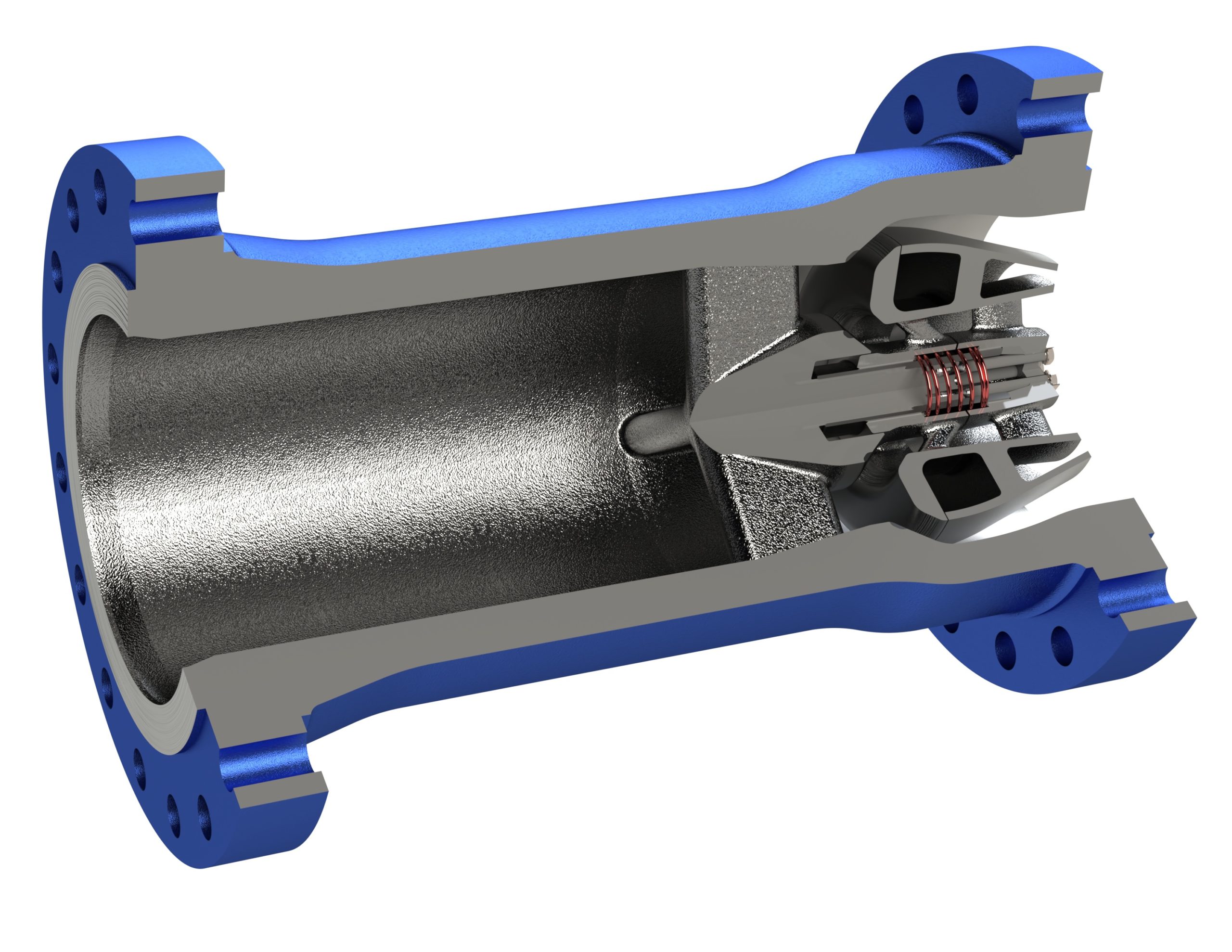

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

Additional information

| Valve Size | 12" to 88" |

|---|---|

| Pressure Class Standard | ASME B16.34, API 6A |

| Pressure Class Range | Class 150, 300, 600, 900, 1500, 2500, 4500; API 2000, 3000, 5000, 10000, 15000, 20000 |

| Body | One-Piece Body |

| End Connections | Flanged, Hub-End, Butt-Weld, Socket-Weld |

| Face-to-Face Standard | API 6D |

| Disc Type | Ring |

| Guiding | Radial |

| Seating | Metal-to-Metal |

| Flow | Axial |

| Type | Non-Slam Anti-Surge |

| Media Application | Liquids, Gases |

| Shut-Off Classification | API 598, ISO 5208 Rate E |

Features & Benefits

- The streamlined internals of the axial check valve range allow for a turbulence free flow path through and around the disc

- The high capacity, smooth flow path results in low pressure drop across all of the axial type valves

- Noreva axial check valve designs use no soft parts and are therefore inherently fire-safe

- There are no wearing parts, for clean services, making it maintenance free

- The springs are sized according to the flow rates to ensure that the valves are in the fully open position during normal use

- The axial design ensures that the disc remains light and responsive even in large sizes

- Mounted on a multiple helical spring and radial guide assembly, the disc moves freely without any frictional forces

- With a flow path both around and through the centre of the disc the flow capacity of the valve is best in class

- Low weight discs, short stroke lengths and spring assistance combine to ensure that it responds quickest to change in flow direction

- The fast response ensures reverse velocity cannot build up to a level that can damage pumps, pipes or related equipment

- Pressure surges can occur when a valve is closed against a moving body of fluid, the quick closure results in a considerably lower pressure peak

Standards & Certifications

| Certifications | Canadian Registration Number (CRN) |

|---|---|

| ANSI NSF 61 – Drinking Water System Components – Health Effects | |

| PED 2014/68/EU CE Mark | |

| Design Standards | ASME B16.47 – Large Diameter Steel Flanges |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.9 – Factory-Made Wrought Buttwelding Fittings | |

| ASME B16.10 – Face to Face & End Dimenions of Valves | |

| ASME B16.11 – Forged Fittings, Socket-Welding & Threaded | |

| ASME B16.25 – Buttwelding Ends | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding End | |

| ASME SA Materials | |

| ASTM A Materials | |

| Quality | IS0 9001:2015 |