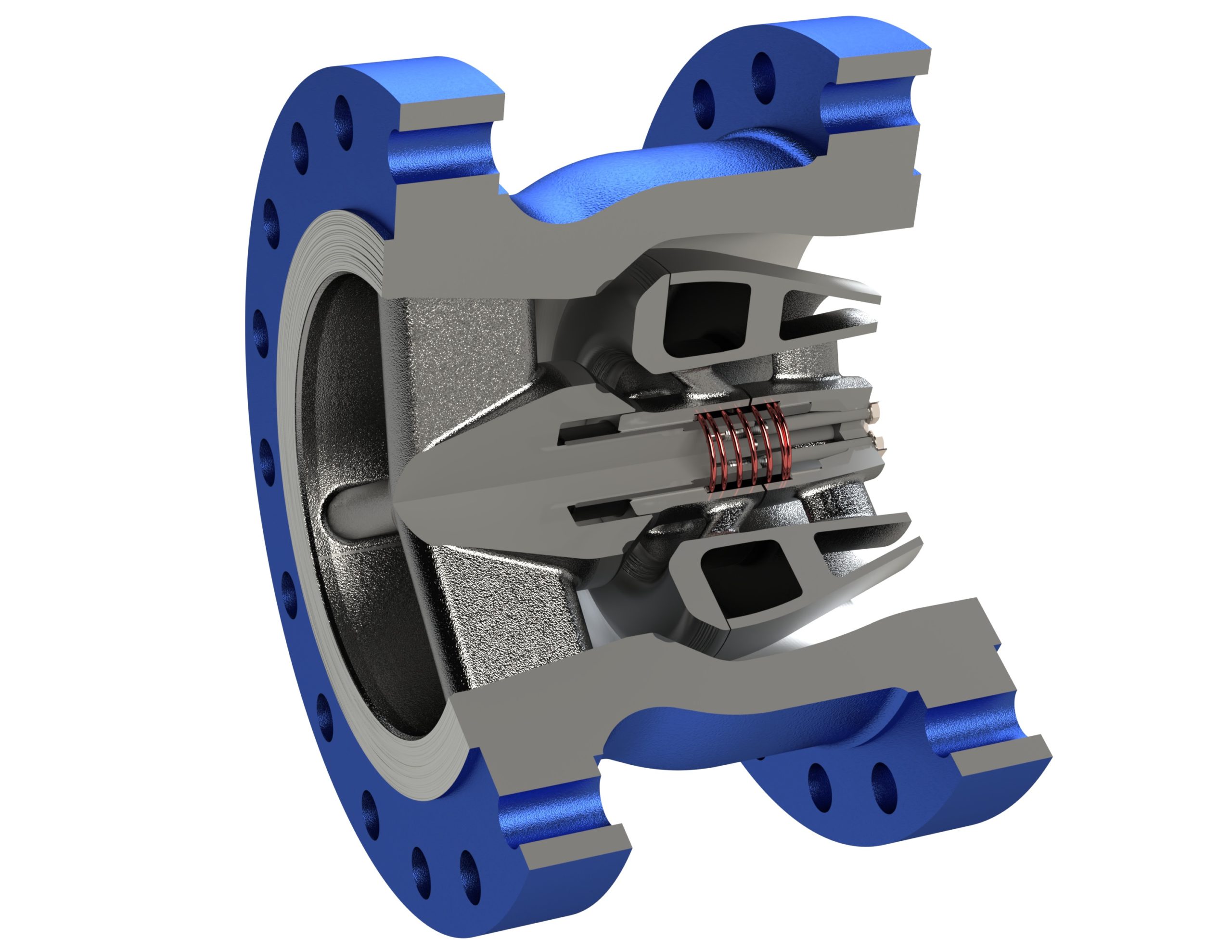

Noreva’s NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Additional information

| Valve Size | 12" to 88" |

|---|---|

| Pressure Class Standard | ASME B16.34 |

| Pressure Class Range | Class 150, 300, 600, 900, 1500, 2500 |

| Body | One-Piece Body |

| End Connections | Flanged, Hub-End, Butt-Weld, Socket-Weld |

| Face-to-Face Standard | Manufacturer Standard |

| Disc Type | Ring |

| Guiding | Centre |

| Seating | Metal-to-Metal |

| Flow | Axial |

| Type | Non-Slam Anti-Surge |

| Media Application | Gases |

| Shut-Off Classification | API 598, ISO 5208 Rate E |

Features & Benefits

- The streamlined internals of the axial check valve range allow for a turbulence free flow path through and around the disc

- The high capacity, smooth flow path results in low pressure drop across all of the axial type valves

- Noreva axial check valve designs use no soft parts and are therefore inherently fire-safe

- There are no wearing parts, for clean services, making it maintenance free

- The springs are sized according to the flow rates to ensure that the valves are in the fully open position during normal use

- The axial design ensures that the disc remains light and responsive even in large sizes

- Mounted on a multiple helical spring and radial guide assembly, the disc moves freely without any frictional forces

- With a flow path both around and through the centre of the disc the flow capacity of the valve is best in class

- Low weight discs, short stroke lengths and spring assistance combine to ensure that it responds quickest to change in flow direction

- The fast response ensures reverse velocity cannot build up to a level that can damage pumps, pipes or related equipment

- Pressure surges can occur when a valve is closed against a moving body of fluid, the quick closure results in a considerably lower pressure peak

Standards & Certifications

| Certifications | Canadian Registration Number (CRN) |

|---|---|

| ANSI NSF 61 – Drinking Water System Components – Health Effects | |

| PED 2014/68/EU CE Mark | |

| Design Standards | ASME B16.47 – Large Diameter Steel Flanges |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.9 – Factory-Made Wrought Buttwelding Fittings | |

| ASME B16.10 – Face to Face & End Dimenions of Valves | |

| ASME B16.11 – Forged Fittings, Socket-Welding & Threaded | |

| ASME B16.25 – Buttwelding Ends | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding End | |

| ASME SA Materials | |

| ASTM A Materials | |

| Quality | IS0 9001:2015 |