Flowserve’s history began over 200 years ago, and today Flowserve employs more than 17,500 associates in 300-plus locations around the world, including over 180 quick response centers that provide aftermarket parts and services to customers. And Flowserve offers more than 100 distinct pump models and a wide range of valve and seal products.

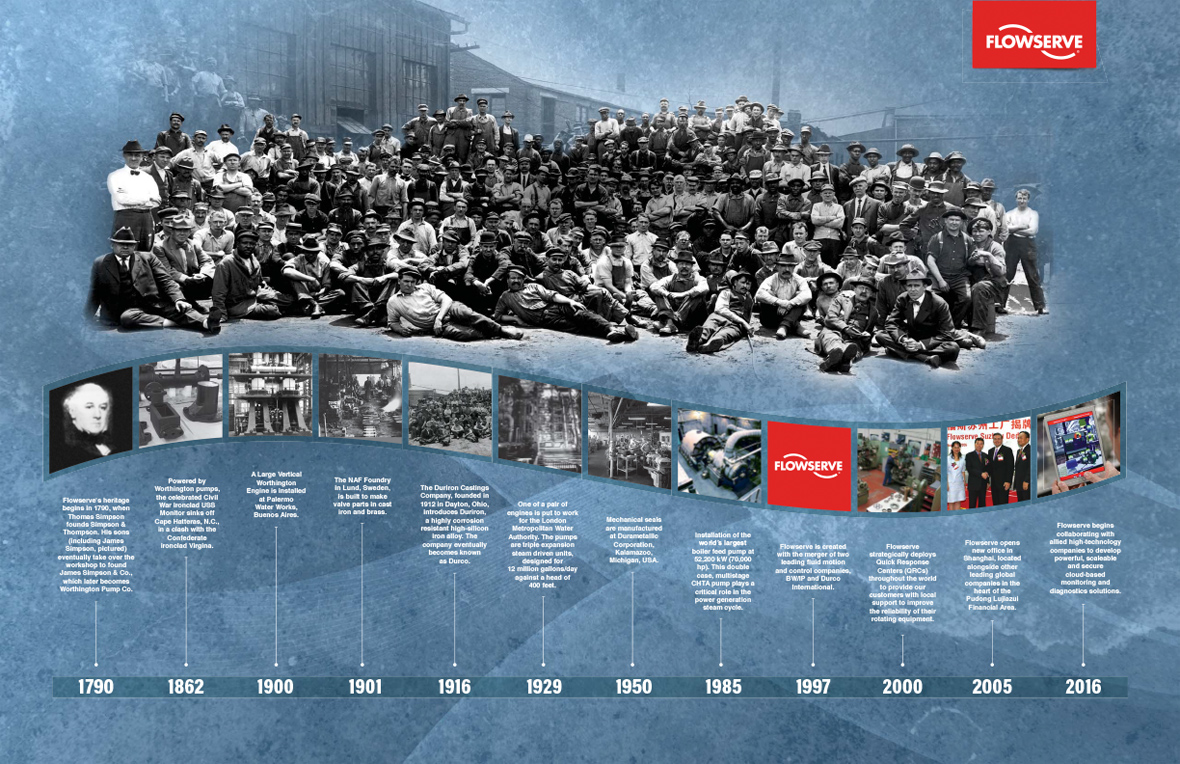

Today’s Flowserve is built on a rich and stable history of innovation. Although incorporated as a public company on the New York Stock Exchange in 1997, their heritage dates back to the founding of Simpson & Thompson in 1790 in Great Britain. This pioneering company later became Worthington Simpson Pumps, now part of the Flowserve family of brands.

Today, Flowserve is a publicly traded corporation with $4 Billion in annual sales, 17,500+ employees, operations in 50+ countries and 300+ locations worldwide.

Through their unmatched combination of products, engineering and aftermarket services, they help customers achieve tangible business results: lower operating costs, optimized performance, prolonged equipment life, mitigated risks and higher productivity.

Around the world, Flowserve is striving to create extraordinary flow control solutions to make the world better for everyone.

From deep ocean floors to remote well fields and oil sands. From up stream production to transportation to refining. No matter how remote the locations, they have the pump, valve and seal solutions you need to construct and maintain your operations.

Flowserve’s high-quality equipment is built to withstand even the most extreme conditions. Backed by service and support teams around the globe, they are also able to provide rapid response in case of outages, thereby minimizing downtime and maximizing productivity. And, as pioneers in the renewable energy industry, Flowserve can guide you through emerging technologies, such as cellulosic ethanol production, to keep you at the forefront of innovation.

Flowserve offers customers an extensive range of design features and corrosion-resistant materials and materials application expertise. Their technology considers safety, reliability, environmental and life cycle solutions for the tough applications in chemical processing.

They introduced and pioneered chemical processing pumps and valves as far back as 75 years ago. Since then, they have created and implemented the industry’s important milestones, including:

Flowserve has earned an unequaled reputation for innovative chemical process pump, valve and seal systems technologies.

Power industries, such as nuclear, conventional steam, combined cycle, concentrated solar power, biomass and MSW, and geothermal have stringent quality and safety standards. Flowserve designs high-quality powerful solutions that can get you up and running quickly and keep you up and running. We are constantly innovating to deliver improved efficiency with an eye on emerging clean power generation technologies.

Flowserve solutions have been hard at work providing fresh water to major urban projects and supporting some of the world’s largest environment restoration projects. As the water industry faces supply and demand challenges related to global population growth, increased consumption and urbanization, Flowserve continues to provide reliable and efficient solutions in industries, such as water, wastewater, agriculture, water management, and desalination.

Regardless of application, Flowserve can provide the solution. Whether your main concern is weathering corrosive and other exceptionally tough conditions, or ensuring consistent and precise output, Flowserve has solutions to handle the demands of your industry. They can equip your plant with products and deliver service offerings ranging from front-end project engineering support to reliable and responsive maintenance and repair that minimizes unexpected downtime. All the while, they help maintain the safety of your people and the integrity of the surrounding environment. Flowserve provides products and support for the following:

Contact us for more information about how Flowserve products can meet your operation needs.