-

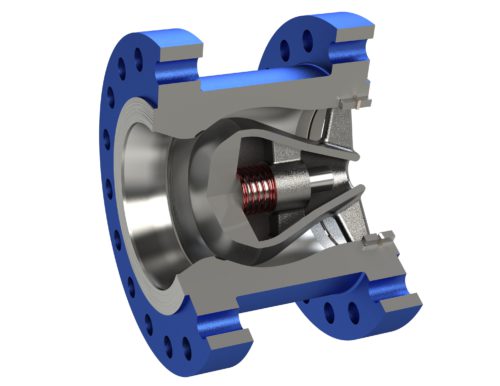

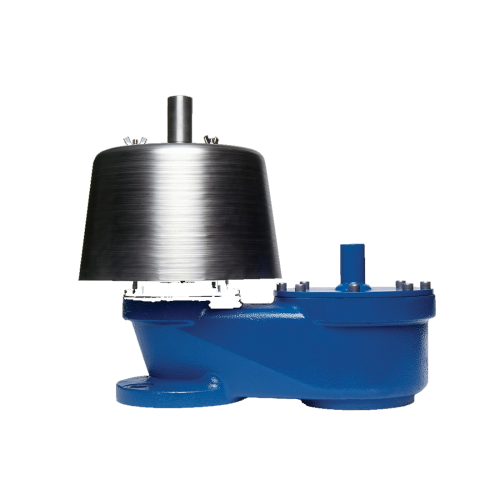

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. -

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD)

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD) -

The Vahn-Tech Series VT-BV-TE is an API 6D compliant and monogrammed top entry trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed.

The Vahn-Tech Series VT-BV-TE is an API 6D compliant and monogrammed top entry trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed. -

The Vahn-Tech Series VT-BV-T is an API 6D compliant and monogrammed trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed.

The Vahn-Tech Series VT-BV-T is an API 6D compliant and monogrammed trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed. -

The Vahn-Tech Series VT-BV floating ball valves are designed to provide maximum service life and durability. Designed with extensive safety considerations including provision of locking devices, blow-out proof stems and prevention of misalignment of lever handles provide safe handling in the field. To ensure smooth plant operation, antistatic devices, fire safe seal design and cavity pressure relief features are provided.

The Vahn-Tech Series VT-BV floating ball valves are designed to provide maximum service life and durability. Designed with extensive safety considerations including provision of locking devices, blow-out proof stems and prevention of misalignment of lever handles provide safe handling in the field. To ensure smooth plant operation, antistatic devices, fire safe seal design and cavity pressure relief features are provided. -

The Vahn-Tech Series TOV and TOBF triple offset butterfly valves are designed to meet the critical zero-leakage isolation requirements for industry applications. Split into two primary design categories, floating and fixed seats, there's versatility in the selection to match your process requirements and project economics.

The Vahn-Tech Series TOV and TOBF triple offset butterfly valves are designed to meet the critical zero-leakage isolation requirements for industry applications. Split into two primary design categories, floating and fixed seats, there's versatility in the selection to match your process requirements and project economics. -

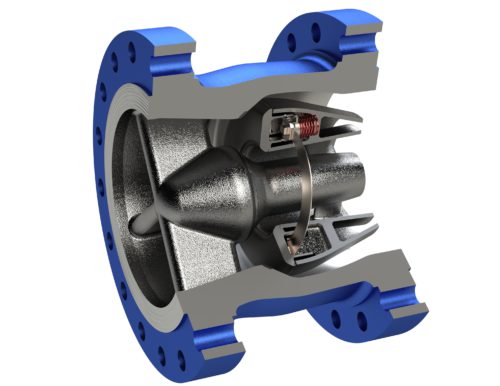

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

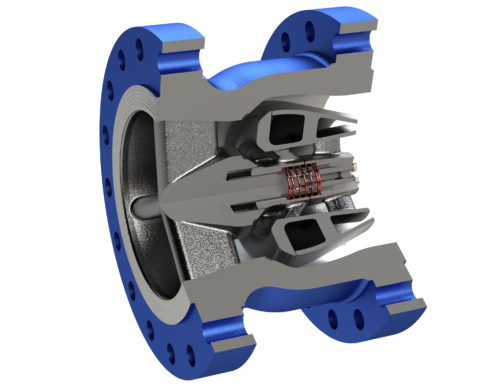

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together.

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND)

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND) -

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

Vahn-Tech Series DOBF is a cost-effective butterfly valve solution for isolation valve applications. Providing lighter weight, smaller face-to-face, and simple quarter-turn rotary movement, a double-offset butterfly valve design is a great solution for zero-leakage isolation relative to ball valves for large sizes. With the eccentric disc designed to reduce the rubbing of the seat it drastically reduces torque requirements for actuation while extending seat life expectancy.

Vahn-Tech Series DOBF is a cost-effective butterfly valve solution for isolation valve applications. Providing lighter weight, smaller face-to-face, and simple quarter-turn rotary movement, a double-offset butterfly valve design is a great solution for zero-leakage isolation relative to ball valves for large sizes. With the eccentric disc designed to reduce the rubbing of the seat it drastically reduces torque requirements for actuation while extending seat life expectancy. -

Vahn-Tech DK Series knife gate valves are soft sealing shut off valves that are light weight with compact construction, and convenient to install and use. Valves are in full port design and with small flow resistance. When the gate is open, direct current flows between valve and pipeline. Valves can be operated manually with handwheel, or with automatic actuator for remote operation. The cone-shape design of the gates provides strong cutting force. The die-casting rubber seats are with bi-directional sealing. The main advantage of the valves is that when fully open, the medium will not flow into the valve chest, which prevents the pulp from settling in the valve chest and thus reducing the maintenance cost.

Vahn-Tech DK Series knife gate valves are soft sealing shut off valves that are light weight with compact construction, and convenient to install and use. Valves are in full port design and with small flow resistance. When the gate is open, direct current flows between valve and pipeline. Valves can be operated manually with handwheel, or with automatic actuator for remote operation. The cone-shape design of the gates provides strong cutting force. The die-casting rubber seats are with bi-directional sealing. The main advantage of the valves is that when fully open, the medium will not flow into the valve chest, which prevents the pulp from settling in the valve chest and thus reducing the maintenance cost. -

Vahn-Tech DF Series square knife gate valve is mainly used as pneumatic on/off valve for process control in pulp making slurry or sewage treatment. It is particularly suitable to serve as a residue discharger on equipment such as stock cleaners, gravity separators and hydra pulper in the paper making industry.

Vahn-Tech DF Series square knife gate valve is mainly used as pneumatic on/off valve for process control in pulp making slurry or sewage treatment. It is particularly suitable to serve as a residue discharger on equipment such as stock cleaners, gravity separators and hydra pulper in the paper making industry. -

Vahn-Tech DC Series knife gate valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with handwheel, or can be automated with pneumatic cylinder or electric actuator for remote operation. The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles. The knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing.

Vahn-Tech DC Series knife gate valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with handwheel, or can be automated with pneumatic cylinder or electric actuator for remote operation. The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles. The knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing. -

Vahn-Tech DB Series funnel knife gate valve is used in service as a pneumatic residue discharge valve in pulp making, paper making and sewage treatment. This type of valve is well suited for high consistency media containing solids, fiber or residue, serving as a residue discharge valve on stock cleaners, gravity separators or pressurized screens. The "funnel" at the bottom of the collects waste discharged from the valve body during the closing stroke. This greatly reduces the wear between the body and gate, and prolongs the life cycle of the valve.

Vahn-Tech DB Series funnel knife gate valve is used in service as a pneumatic residue discharge valve in pulp making, paper making and sewage treatment. This type of valve is well suited for high consistency media containing solids, fiber or residue, serving as a residue discharge valve on stock cleaners, gravity separators or pressurized screens. The "funnel" at the bottom of the collects waste discharged from the valve body during the closing stroke. This greatly reduces the wear between the body and gate, and prolongs the life cycle of the valve. -

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience.

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience. -

The Ranger QCT is a universal eccentric plug valve with a pneumatic spring diaphragm actuator that can be utilized in many valve applications, most common in steam service. With a different body and trim constructions, it can provide longer life on difficult services. The QCT concept (Quick Change Trim) allows access to the valve body, allowing the use of many valves inserts to meet specific application needs. This feature makes the Ranger QCT very maintenance friendly.

The Ranger QCT is a universal eccentric plug valve with a pneumatic spring diaphragm actuator that can be utilized in many valve applications, most common in steam service. With a different body and trim constructions, it can provide longer life on difficult services. The QCT concept (Quick Change Trim) allows access to the valve body, allowing the use of many valves inserts to meet specific application needs. This feature makes the Ranger QCT very maintenance friendly. -

The Flowserve Limitorque QX, non-intrusive electric actuator is designed for a wide range of environmental applications in power, chemicals, water, oil & gas, and general industries. The QX design builds on more than 20 years of proven MX technology to provide all the user-preferred features in a quarter-turn smart actuator package.

The Flowserve Limitorque QX, non-intrusive electric actuator is designed for a wide range of environmental applications in power, chemicals, water, oil & gas, and general industries. The QX design builds on more than 20 years of proven MX technology to provide all the user-preferred features in a quarter-turn smart actuator package. -

The Model POSR-1 is a pressure-reducing regulator that can be used as a pressure-loaded regulator or as a pilot operated by supplying an external pilot through the main body by a tapped connection. The external pilot valve is supplied from a main valve body-tapped connection. It can handle pressure drops up to 200 psi (13.8 Bar).

The Model POSR-1 is a pressure-reducing regulator that can be used as a pressure-loaded regulator or as a pilot operated by supplying an external pilot through the main body by a tapped connection. The external pilot valve is supplied from a main valve body-tapped connection. It can handle pressure drops up to 200 psi (13.8 Bar). -

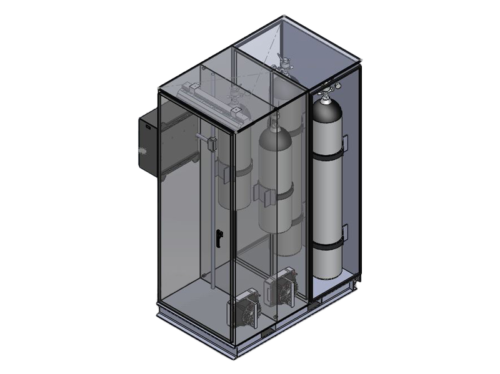

The POD series is engineered for ultimate temperature control and accessibility. It encloses the control system and required plenums in a cabinet large enough for site personnel to enter. The rear of the cabinet has a drop down ramp access to the high-pressure nitrogen cylinders for when replacements are required. Nitrogen adjustment can be made without opening the heated area.With our ability to fabricate and test in the USA and Canada, we can design to build the POD series control system to your required specifications. All engineering phases necessary will be exercised with this elite control system technology.

The POD series is engineered for ultimate temperature control and accessibility. It encloses the control system and required plenums in a cabinet large enough for site personnel to enter. The rear of the cabinet has a drop down ramp access to the high-pressure nitrogen cylinders for when replacements are required. Nitrogen adjustment can be made without opening the heated area.With our ability to fabricate and test in the USA and Canada, we can design to build the POD series control system to your required specifications. All engineering phases necessary will be exercised with this elite control system technology. -

The Model P1 is a single stage pressure reducing regulator designed for gases and liquids with inlet pressures up to 3600 psig (248 Barg) and outlet pressure up to 750 psig. It comes in a wide variety of different trim combinations to adapt to different application requirements such as Hydrogen, high-purity gases, and sour services.

The Model P1 is a single stage pressure reducing regulator designed for gases and liquids with inlet pressures up to 3600 psig (248 Barg) and outlet pressure up to 750 psig. It comes in a wide variety of different trim combinations to adapt to different application requirements such as Hydrogen, high-purity gases, and sour services. -

The Valtek NT 3000 Series Electro-Pneumatic Transducer is an active I/P Transducer that is used with a milliamp electricl control signal. It is interchangeable with the XL Series or Beta Series Pneumatic Positioners and can be mounted on either Valtek Linear or Valtek Rotary Actuators without modification.

The Valtek NT 3000 Series Electro-Pneumatic Transducer is an active I/P Transducer that is used with a milliamp electricl control signal. It is interchangeable with the XL Series or Beta Series Pneumatic Positioners and can be mounted on either Valtek Linear or Valtek Rotary Actuators without modification. -

The Valtek NR diaphragm actuator is a compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 80 psi (6 Bar). The high stiffness and rolling diaphragm provides firm control from 0 to 90 degrees.

The Valtek NR diaphragm actuator is a compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 80 psi (6 Bar). The high stiffness and rolling diaphragm provides firm control from 0 to 90 degrees. -

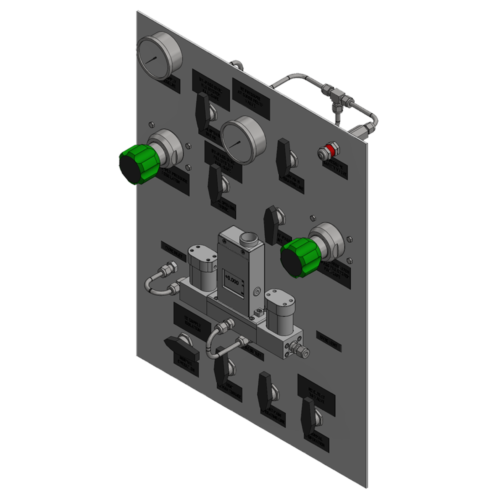

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems.

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems. -

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results.

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results. -

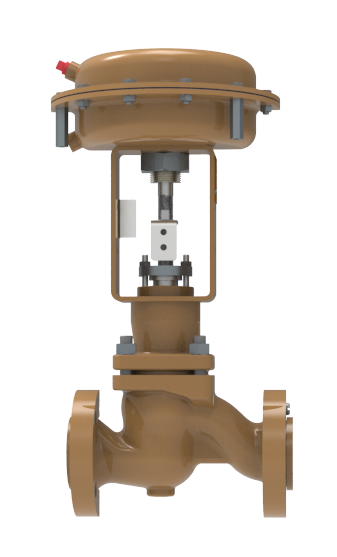

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST. Model 989 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in flanged.

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST. Model 989 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in flanged. -

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST, or CW-12MW/Hast. Model 988 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in various end connections such as raised face flanged, socket weld and NPT.

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST, or CW-12MW/Hast. Model 988 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in various end connections such as raised face flanged, socket weld and NPT. -

Pneumatic Control Valve that can be utilized in general service. The body/trim comes in a variety of material selection that includes Ductile Iron ASTM: A395, Carbon Steel (WCB). Model 964 comes in two different seat constructions: metal (Class IV) and a composition seat (Class VI). This model is available in flanged, socket weld, or NPT.

Pneumatic Control Valve that can be utilized in general service. The body/trim comes in a variety of material selection that includes Ductile Iron ASTM: A395, Carbon Steel (WCB). Model 964 comes in two different seat constructions: metal (Class IV) and a composition seat (Class VI). This model is available in flanged, socket weld, or NPT. -

The Model 4381 is a stainless steel pressure-reducing regulator designed to handle small to mid-capacity flow rates in general. This model is capable of controlling outlet pressure to a level between 2 and 500 psig (0.14 and 34.5 Barg) with a maximum inlet pressure up to 1500 psig. By having thirteen different trim combinations with the option of a soft or metal seat, the model 4381 can be utilized in different applications such as industrial gases, air, oil, steam, water, and, chemical or cryogenic services.

The Model 4381 is a stainless steel pressure-reducing regulator designed to handle small to mid-capacity flow rates in general. This model is capable of controlling outlet pressure to a level between 2 and 500 psig (0.14 and 34.5 Barg) with a maximum inlet pressure up to 1500 psig. By having thirteen different trim combinations with the option of a soft or metal seat, the model 4381 can be utilized in different applications such as industrial gases, air, oil, steam, water, and, chemical or cryogenic services. -

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.