-

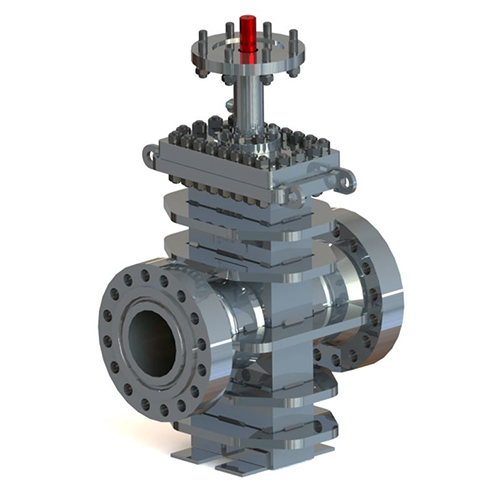

The Valbart TCSGV through conduit slab gate valve is the oil and gas industry's choice for liquid and gas applications requiring reliable, tight shut-off to prevent leakage and minimize losses from process contamination. It is ideal for pipeline applications requiring pigging capability. Its full-bore design features spring-energized seats and a floating slab gate to ensure both low- and high-pressure sealing capabilities. The Valbart TCSGV is manufactured and tested in accordance with API 6D, latest edition. Its design is fully compliant to ASME Section VIII, Division 1. Its design meets API 6D isolation features of block and bleed, double isolation bleed (DIB), double block and bleed, cavity relief, and other requirements commonly specified in the pipeline industry.

The Valbart TCSGV through conduit slab gate valve is the oil and gas industry's choice for liquid and gas applications requiring reliable, tight shut-off to prevent leakage and minimize losses from process contamination. It is ideal for pipeline applications requiring pigging capability. Its full-bore design features spring-energized seats and a floating slab gate to ensure both low- and high-pressure sealing capabilities. The Valbart TCSGV is manufactured and tested in accordance with API 6D, latest edition. Its design is fully compliant to ASME Section VIII, Division 1. Its design meets API 6D isolation features of block and bleed, double isolation bleed (DIB), double block and bleed, cavity relief, and other requirements commonly specified in the pipeline industry. -

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction.

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction. -

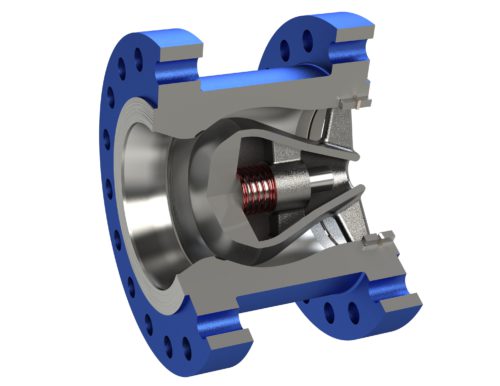

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD)

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD) -

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together.

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. -

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. -

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. -

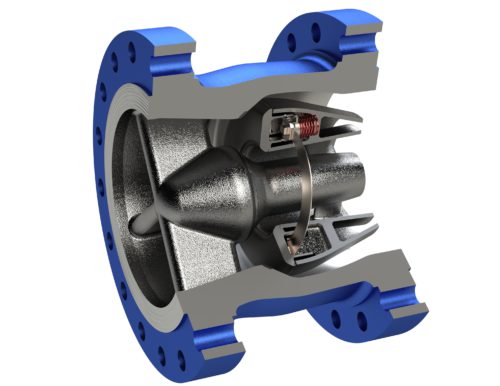

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND)

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND) -

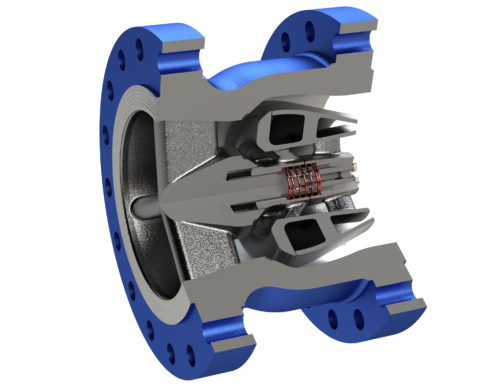

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance. -

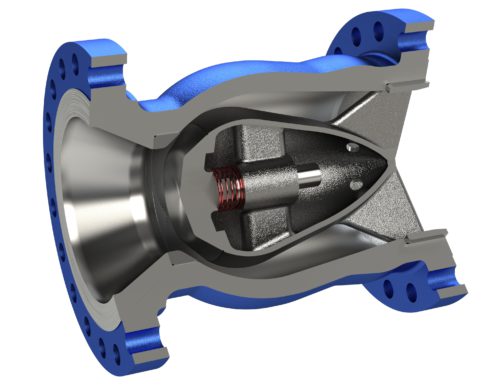

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow.

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow. -

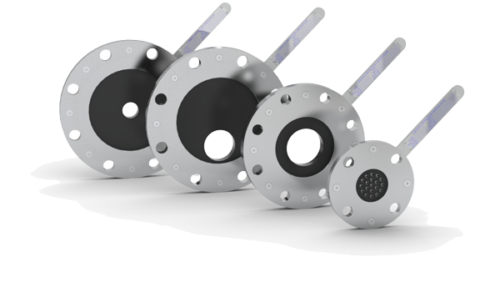

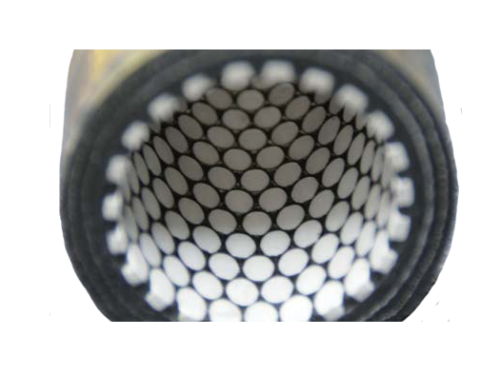

Ceresist ceramic lined pipe spools are designed to outlast linings such as glass, rubber, basalt, hard facings, coatings, trowelable linings, cure-in-place linings, and plastics that are commonly used to extend the life of piping systems. These materials are only a fraction of the hardness and wear resistance of our ceramics, and in the presence of corrosion or high temperatures, most linings become severely incompatible and their use is extremely limited

Ceresist ceramic lined pipe spools are designed to outlast linings such as glass, rubber, basalt, hard facings, coatings, trowelable linings, cure-in-place linings, and plastics that are commonly used to extend the life of piping systems. These materials are only a fraction of the hardness and wear resistance of our ceramics, and in the presence of corrosion or high temperatures, most linings become severely incompatible and their use is extremely limited -

Ceresist ceramic-lined chokes are specified for use in extremely erosive slurries that contain a very high percentage of solids. The large radius entry of the chokes exhibit better consistency and flow recovery characteristics than sharp-edged orifice plates. Furthermore, our ceramic-lined chokes are more compact than venturi-style chokes. The silicon carbide ceramic choke insert is 30 times more wear-resistant than stainless steel, and offers years of maintenance-free service.

Ceresist ceramic-lined chokes are specified for use in extremely erosive slurries that contain a very high percentage of solids. The large radius entry of the chokes exhibit better consistency and flow recovery characteristics than sharp-edged orifice plates. Furthermore, our ceramic-lined chokes are more compact than venturi-style chokes. The silicon carbide ceramic choke insert is 30 times more wear-resistant than stainless steel, and offers years of maintenance-free service. -

Ceresist's CER-1200 fine-grain alumina ceramic is next to diamond in hardness and outlasts steel by 12 times and Ni-hard by 5 times. Ceresist wear-resistant products are a long-term, maintenance-free solution in systems that experience rapid degradation due to sliding abrasion, erosion, and impact - even in highly corrosive or high-temperature services.

Ceresist's CER-1200 fine-grain alumina ceramic is next to diamond in hardness and outlasts steel by 12 times and Ni-hard by 5 times. Ceresist wear-resistant products are a long-term, maintenance-free solution in systems that experience rapid degradation due to sliding abrasion, erosion, and impact - even in highly corrosive or high-temperature services. -

Ceresist CeramFlex™ Series ceramic-lined flexible hoses are ideal for use in highly aggressive services where conventional unlined rubber hoses require frequent replacement. CeramFlex™ hoses may also be used to isolate mechanical vibration or to connect non-stationary equipment. Eliminate unscheduled shut-downs, increase production throughput, and increase profits.

Ceresist CeramFlex™ Series ceramic-lined flexible hoses are ideal for use in highly aggressive services where conventional unlined rubber hoses require frequent replacement. CeramFlex™ hoses may also be used to isolate mechanical vibration or to connect non-stationary equipment. Eliminate unscheduled shut-downs, increase production throughput, and increase profits. -

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs.

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs. -

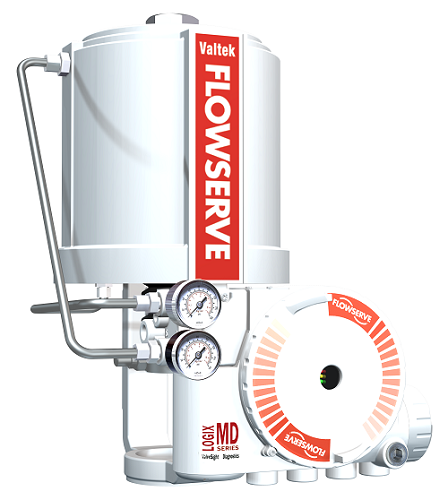

The Logix™ 3200MD+ Digital HART Positioner from Flowserve utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3200MD+ can be easily configured using the local buttons or the ValveSight™ DTM. The Logix 3200MD+ is designed to withstand severe environments; it is equipped with over 100 helpful warning alarms that can warn against potential failure of the valve, actuator and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues.

The Logix™ 3200MD+ Digital HART Positioner from Flowserve utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3200MD+ can be easily configured using the local buttons or the ValveSight™ DTM. The Logix 3200MD+ is designed to withstand severe environments; it is equipped with over 100 helpful warning alarms that can warn against potential failure of the valve, actuator and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues. -

The Flowserve Logix 3400MD Digital Foundation Fieldbus positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3400MD can be easily configured using the local buttons or the ValveSight DTM. Logix 3400MD has a complete diagnostics package that can alert the user to developing conditions that may cause unnecessary upset conditions in the plant.

The Flowserve Logix 3400MD Digital Foundation Fieldbus positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3400MD can be easily configured using the local buttons or the ValveSight DTM. Logix 3400MD has a complete diagnostics package that can alert the user to developing conditions that may cause unnecessary upset conditions in the plant. -

The Flowserve Logix 520MD+ Digital HART Positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 520MD+ Positioner is designed to withstand severe environments; it is equipped with over 130 helpful warning alarms that can warn against potential failure of the valve, actuator, and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues.

The Flowserve Logix 520MD+ Digital HART Positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 520MD+ Positioner is designed to withstand severe environments; it is equipped with over 130 helpful warning alarms that can warn against potential failure of the valve, actuator, and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues. -

The Logix 520MD Series digital positioner combines superior positioning and tuning functions with convenient setup and powerful diagnostic tools. The Logix 520MD positioner uses a multi-variable gain tuning algorithm which allows the positioner to make large step changes with minimal overshoot while achieving the resolution to respond to very small step changes. The Auto-tune procedure cycles the actuator to produce a measured response and selects gain values that provide appropriate actuator performance. The Auto-tune function includes a gain modifier selector that can be used to increase or decrease the calculated gain in order to achieve optimal performance. Easy DIP switch configuration for tuning mode and other common settings. For custom settings, tuning sets can be modified with a handheld or with ValveSight software, to accommodate a wide range of actuator sizes and types.

The Logix 520MD Series digital positioner combines superior positioning and tuning functions with convenient setup and powerful diagnostic tools. The Logix 520MD positioner uses a multi-variable gain tuning algorithm which allows the positioner to make large step changes with minimal overshoot while achieving the resolution to respond to very small step changes. The Auto-tune procedure cycles the actuator to produce a measured response and selects gain values that provide appropriate actuator performance. The Auto-tune function includes a gain modifier selector that can be used to increase or decrease the calculated gain in order to achieve optimal performance. Easy DIP switch configuration for tuning mode and other common settings. For custom settings, tuning sets can be modified with a handheld or with ValveSight software, to accommodate a wide range of actuator sizes and types. -

The Valtek XL Series (XL and XL90), two-stage positioners offer fast and sensitive dynamic response characteristics to meet extremely demanding control objectives. The positioners are available with either an electro-pneumatic (I/P) transducer module for milliamp current control signals or a pneumatic module for aircontrol signals. Designed for high performance, these positioners are field reversible and ruggedly built for reliability in severe industrial environments.

The Valtek XL Series (XL and XL90), two-stage positioners offer fast and sensitive dynamic response characteristics to meet extremely demanding control objectives. The positioners are available with either an electro-pneumatic (I/P) transducer module for milliamp current control signals or a pneumatic module for aircontrol signals. Designed for high performance, these positioners are field reversible and ruggedly built for reliability in severe industrial environments. -

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments.

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments. -

The Valtek NT 3000 Series Electro-Pneumatic Transducer is an active I/P Transducer that is used with a milliamp electricl control signal. It is interchangeable with the XL Series or Beta Series Pneumatic Positioners and can be mounted on either Valtek Linear or Valtek Rotary Actuators without modification.

The Valtek NT 3000 Series Electro-Pneumatic Transducer is an active I/P Transducer that is used with a milliamp electricl control signal. It is interchangeable with the XL Series or Beta Series Pneumatic Positioners and can be mounted on either Valtek Linear or Valtek Rotary Actuators without modification. -

The StarPac 3 intelligent control system offers repeatability, accuracy and quick system response time with a small footprint and simple installation. It can stand alone or be integrated into a system, and is available for a variety of applications including oil and gas, chemical, paper, mining, industrial gases and power generation. Unique to the market, StarPac intelligent control systems give users an integrated view of the process at a single point and can improve plant operation at a lower installed cost than conventional control systems. The StarPac 3 builds on previous designs. Upgraded features include explosion-proof housing, USB and infrared interface, updated electronics, stainless steel options and enhanced positioner functions.

The StarPac 3 intelligent control system offers repeatability, accuracy and quick system response time with a small footprint and simple installation. It can stand alone or be integrated into a system, and is available for a variety of applications including oil and gas, chemical, paper, mining, industrial gases and power generation. Unique to the market, StarPac intelligent control systems give users an integrated view of the process at a single point and can improve plant operation at a lower installed cost than conventional control systems. The StarPac 3 builds on previous designs. Upgraded features include explosion-proof housing, USB and infrared interface, updated electronics, stainless steel options and enhanced positioner functions. -

Valtek VL series spring cylinder linear actuators are powerful, compact, high-performance pneumatic actuators that provide solid throttling or on-off operation for automatic control valves. The positioner supplies air to both sides of the piston, providing stiff, precise movement and high-frequency response and quick stroke speeds.

Valtek VL series spring cylinder linear actuators are powerful, compact, high-performance pneumatic actuators that provide solid throttling or on-off operation for automatic control valves. The positioner supplies air to both sides of the piston, providing stiff, precise movement and high-frequency response and quick stroke speeds. -

The Kämmer KA & KP Series 2 actuators types P2, P3, P4 and P5 are powerful and compact. By using stainless steel material the actuators have far reaching resistance to corrosion even without a protective coating. Accessories such as positioners, limit switches or solenoid valves etc. can be fitted according to NAMUR. Compact versions with enclosed accessories are also available.

The Kämmer KA & KP Series 2 actuators types P2, P3, P4 and P5 are powerful and compact. By using stainless steel material the actuators have far reaching resistance to corrosion even without a protective coating. Accessories such as positioners, limit switches or solenoid valves etc. can be fitted according to NAMUR. Compact versions with enclosed accessories are also available. -

The Valtek VR rotary cylinder actuator is a high pressure, compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The standard splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 150 psi (10.3 Bar) to eliminate the need for a pressure regulator. The high stiffness provides firm control from 0 to 90 degrees.

The Valtek VR rotary cylinder actuator is a high pressure, compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The standard splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 150 psi (10.3 Bar) to eliminate the need for a pressure regulator. The high stiffness provides firm control from 0 to 90 degrees. -

The Valtek NR diaphragm actuator is a compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 80 psi (6 Bar). The high stiffness and rolling diaphragm provides firm control from 0 to 90 degrees.

The Valtek NR diaphragm actuator is a compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 80 psi (6 Bar). The high stiffness and rolling diaphragm provides firm control from 0 to 90 degrees. -

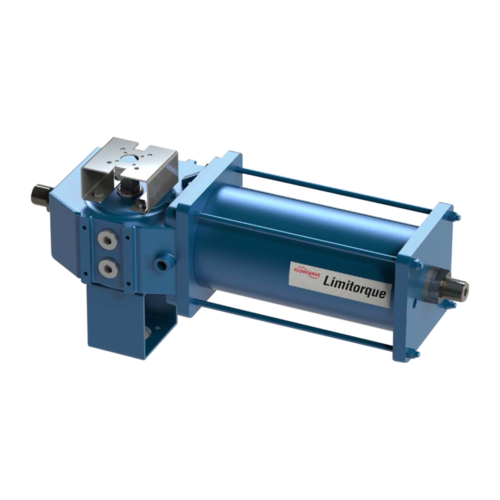

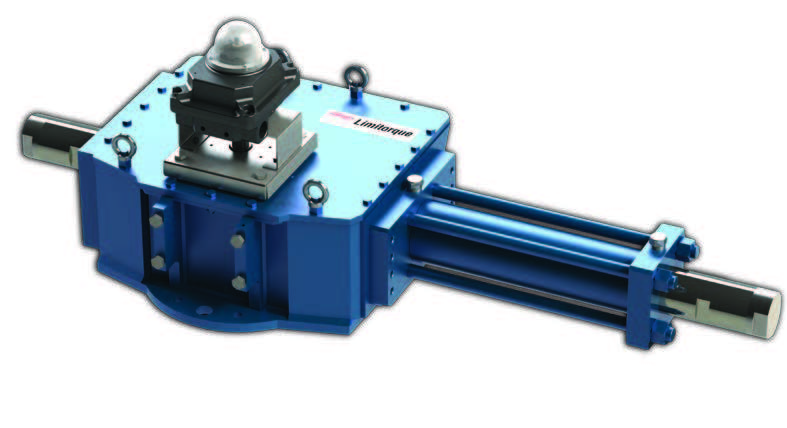

Limitorque's LPS heavy-duty pneumatic scotch yoke actuator is the innovative, reliable choice for on/off, inching and modulating automation applications on quarter-turn medium-to-large sized valves in general and protective services for the oil & gas market. LPS actuators provide up to 550 kNm (405 659 ft-lb) of heavy-duty torque. Enhanced performance is achieved by using a superior Scotch yoke support design that significantly reduces transverse loads. LPS actuators feature modular construction to minimize repair time and initial cost while maximizing process availability.

Limitorque's LPS heavy-duty pneumatic scotch yoke actuator is the innovative, reliable choice for on/off, inching and modulating automation applications on quarter-turn medium-to-large sized valves in general and protective services for the oil & gas market. LPS actuators provide up to 550 kNm (405 659 ft-lb) of heavy-duty torque. Enhanced performance is achieved by using a superior Scotch yoke support design that significantly reduces transverse loads. LPS actuators feature modular construction to minimize repair time and initial cost while maximizing process availability. -

The Limitorque LPC series is a compact pneumatic scotch yoke actuator for on/off, inching and light modulating applications on quarter-turn small-to-medium sized valves in general and protective services for the oil & gas market. Equipment performance and safety standards continue to evolve and increase across the infrastructure industries. These stringent demands are particularly dynamic in oil and gas, where perpetually increasing emphases on personnel safety and equipment uptime is the norm. To more aggressively meet these demands, Flowserve Limitorque is offering the LPC Pneumatic Compact Scotch yoke actuator, specifically designed to meet or exceed the latest and most rigorous of these requirements.

The Limitorque LPC series is a compact pneumatic scotch yoke actuator for on/off, inching and light modulating applications on quarter-turn small-to-medium sized valves in general and protective services for the oil & gas market. Equipment performance and safety standards continue to evolve and increase across the infrastructure industries. These stringent demands are particularly dynamic in oil and gas, where perpetually increasing emphases on personnel safety and equipment uptime is the norm. To more aggressively meet these demands, Flowserve Limitorque is offering the LPC Pneumatic Compact Scotch yoke actuator, specifically designed to meet or exceed the latest and most rigorous of these requirements. -

Ever since its introduction back in the 1980s, NAF Turnex has proven its unique features and maintenance-free operation. The robust linkage system with bushing provides an optimum torque curve for quarter turn valves and eliminates play. This makes it ideal for rotary control applications. NAF Turnex is an integrated part in the NAF control valve package with a unique direct mounting concept. The actuator is also used for on/off service and has adjustable end-stops in both directions. Ever since we developed this state-of-the-art actuator the spare parts have been the same. This, combined with a unique system of sleeves, for different stem diameters, minimizes the number of spare parts.

Ever since its introduction back in the 1980s, NAF Turnex has proven its unique features and maintenance-free operation. The robust linkage system with bushing provides an optimum torque curve for quarter turn valves and eliminates play. This makes it ideal for rotary control applications. NAF Turnex is an integrated part in the NAF control valve package with a unique direct mounting concept. The actuator is also used for on/off service and has adjustable end-stops in both directions. Ever since we developed this state-of-the-art actuator the spare parts have been the same. This, combined with a unique system of sleeves, for different stem diameters, minimizes the number of spare parts. -

The DFS series scotch and Yoke Pneumatic Actuators are heavy-duty actuators for operating large diameter ball valves, butterfly valves, plug valves and other 90˚ rotating mechanism. Available with two yoke deigns namely symmetrical design and canted yoke design. Cylinder blocks are plated with hard chromium to increase the service life of the actuators. The piston rod and guide block connection superior surface finish and the self-lubricating bearings maximize the input energy transfer directly to the valve stem and ensure reliable operation over the service life of the actuator. Can be supplied with the complete line of controls and monitoring accessories, including hand wheel, hydraulic manual override, limit switches, solenoid valves, positioners and other control accessories.

The DFS series scotch and Yoke Pneumatic Actuators are heavy-duty actuators for operating large diameter ball valves, butterfly valves, plug valves and other 90˚ rotating mechanism. Available with two yoke deigns namely symmetrical design and canted yoke design. Cylinder blocks are plated with hard chromium to increase the service life of the actuators. The piston rod and guide block connection superior surface finish and the self-lubricating bearings maximize the input energy transfer directly to the valve stem and ensure reliable operation over the service life of the actuator. Can be supplied with the complete line of controls and monitoring accessories, including hand wheel, hydraulic manual override, limit switches, solenoid valves, positioners and other control accessories. -

The Limitorque LRP provides durable functionality and prolonged service life through unique features such as piston support rods within the actuator, ensuring that side loads generated by the pistons are transmitted through bearings in the end cap and not the body. This eliminates the need for the body to be used as a loadbearing surface and promotes longer service life. The support rod design of the Limitorque LRP actuator distinguishes it from the standard rack and pinion design and offers reliable operation, performance stability and longer service life.

The Limitorque LRP provides durable functionality and prolonged service life through unique features such as piston support rods within the actuator, ensuring that side loads generated by the pistons are transmitted through bearings in the end cap and not the body. This eliminates the need for the body to be used as a loadbearing surface and promotes longer service life. The support rod design of the Limitorque LRP actuator distinguishes it from the standard rack and pinion design and offers reliable operation, performance stability and longer service life. -

The Vahn-Tech Series DFS is an economic rack and pinion style pnuematic actuator, with both captured coil spring-return and double-acting configurations. With standardized accessory (VDI/VDE 3845) and valve (ISO 5211) mounting pads, packaging with Vahn-Tech and third-party valves and accessories is simplified and easy.

The Vahn-Tech Series DFS is an economic rack and pinion style pnuematic actuator, with both captured coil spring-return and double-acting configurations. With standardized accessory (VDI/VDE 3845) and valve (ISO 5211) mounting pads, packaging with Vahn-Tech and third-party valves and accessories is simplified and easy. -

The Vahn-Tech Series 4X4 packs more than double the torque of conventional rack and pinion actuators thanks to its four pistons generating torque around a centrally located pinion. With more pistons in the actuator, this allows the actuator being more compact with size reduced by more than 30% compared to double piston actuator of the same torque. With four small cylinders each located on one of four sides of the unit and at a given air pressure, the 4x4 produces the same torque output as double piston models using smaller diameter pistons and a narrower pinion. The narrower pinion allows the pistons to travel shorter distances so that they can move faster from one position to the next.

The Vahn-Tech Series 4X4 packs more than double the torque of conventional rack and pinion actuators thanks to its four pistons generating torque around a centrally located pinion. With more pistons in the actuator, this allows the actuator being more compact with size reduced by more than 30% compared to double piston actuator of the same torque. With four small cylinders each located on one of four sides of the unit and at a given air pressure, the 4x4 produces the same torque output as double piston models using smaller diameter pistons and a narrower pinion. The narrower pinion allows the pistons to travel shorter distances so that they can move faster from one position to the next. -

The Limitorque LHS and LHH Hydraulic Scotch Yoke actuator series are designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry. LHS and LHH are ideal where hydraulic motive power is preferred for the operation of quarter-turn valves and for applications requiring a robust heavy duty design, long service life, high-torque and high-speed operation.

The Limitorque LHS and LHH Hydraulic Scotch Yoke actuator series are designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry. LHS and LHH are ideal where hydraulic motive power is preferred for the operation of quarter-turn valves and for applications requiring a robust heavy duty design, long service life, high-torque and high-speed operation. -

The Limitorque LDG Direct Gas powered scotch yoke actuator series is specifically designed to be operated by high pressure natural gas, or any other high pressure pneumatic fluid up to a maximum of 105 barg (1500 psig). LDG actuators are ideal for pipeline applications where no external sources of motive power are present and provide a robust heavy duty design and long service life with industry leading maintenance intervals. This makes them the actuator of choice for installation in remote or unmanned facilities.

The Limitorque LDG Direct Gas powered scotch yoke actuator series is specifically designed to be operated by high pressure natural gas, or any other high pressure pneumatic fluid up to a maximum of 105 barg (1500 psig). LDG actuators are ideal for pipeline applications where no external sources of motive power are present and provide a robust heavy duty design and long service life with industry leading maintenance intervals. This makes them the actuator of choice for installation in remote or unmanned facilities. -

The Vahn-Tech Series VT-OMX Explosion Proof Electric Actuators offer torque ranges from 35 Nm to 1,500 Nm (310 in-lb to 13,280 in-lb). All models are ISO 5211 compliant and are equipped with a visual position indicator. The manual override can be operated without clutch and brake. VT-OMX series explosion-proof quarter-turn electric actuators are structured as flame-proof and combustible dust-proof. The directive and standards marking are II2GD Ex db IIB T4 Gb, Ex tb IIIC T130°C Db. They are classified as Zone 1 or Zone 2, containing Group II A and Group II B gases, Zone 21 or Zone 22, containing combustible dust atmospheres or explosive gas atmospheres and combustible dust atmospheres. Temperature group T1 to T4.

The Vahn-Tech Series VT-OMX Explosion Proof Electric Actuators offer torque ranges from 35 Nm to 1,500 Nm (310 in-lb to 13,280 in-lb). All models are ISO 5211 compliant and are equipped with a visual position indicator. The manual override can be operated without clutch and brake. VT-OMX series explosion-proof quarter-turn electric actuators are structured as flame-proof and combustible dust-proof. The directive and standards marking are II2GD Ex db IIB T4 Gb, Ex tb IIIC T130°C Db. They are classified as Zone 1 or Zone 2, containing Group II A and Group II B gases, Zone 21 or Zone 22, containing combustible dust atmospheres or explosive gas atmospheres and combustible dust atmospheres. Temperature group T1 to T4. -

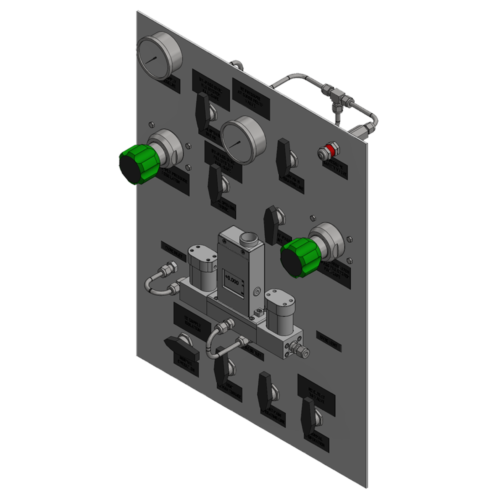

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems.

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems. -

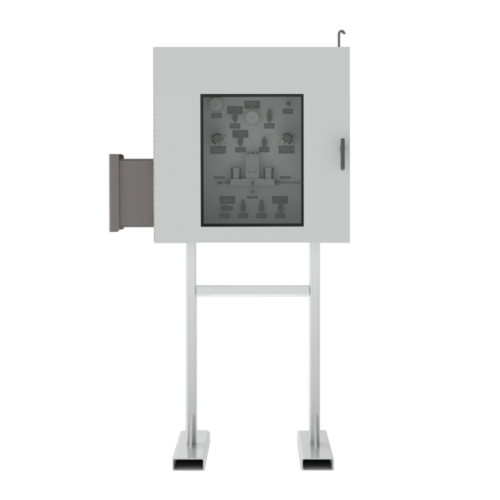

The HK control system provides NCS series functionality with the added protection of an enclosure as well as temperature compensation through internal heating and regulation. This series encloses the entire control system with only externals components being the plenums and nitrogen cylinders. Our stands provide the ability to affix plenums or nitrogen cylinders. Other customer requested options can be integrated into this control system.With the plenum bottles still likely being exposed to the elements, we would recommend investing in our Temperature Control Accessories to minimize pressure compensation within the system.

The HK control system provides NCS series functionality with the added protection of an enclosure as well as temperature compensation through internal heating and regulation. This series encloses the entire control system with only externals components being the plenums and nitrogen cylinders. Our stands provide the ability to affix plenums or nitrogen cylinders. Other customer requested options can be integrated into this control system.With the plenum bottles still likely being exposed to the elements, we would recommend investing in our Temperature Control Accessories to minimize pressure compensation within the system. -

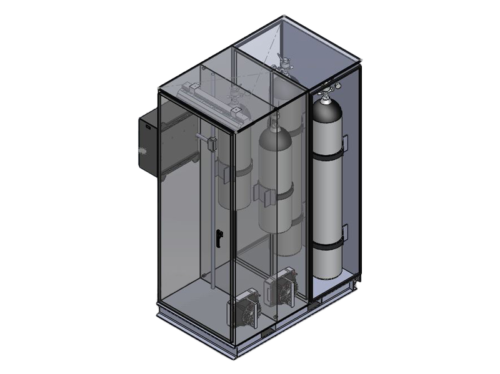

The POD series is engineered for ultimate temperature control and accessibility. It encloses the control system and required plenums in a cabinet large enough for site personnel to enter. The rear of the cabinet has a drop down ramp access to the high-pressure nitrogen cylinders for when replacements are required. Nitrogen adjustment can be made without opening the heated area.With our ability to fabricate and test in the USA and Canada, we can design to build the POD series control system to your required specifications. All engineering phases necessary will be exercised with this elite control system technology.

The POD series is engineered for ultimate temperature control and accessibility. It encloses the control system and required plenums in a cabinet large enough for site personnel to enter. The rear of the cabinet has a drop down ramp access to the high-pressure nitrogen cylinders for when replacements are required. Nitrogen adjustment can be made without opening the heated area.With our ability to fabricate and test in the USA and Canada, we can design to build the POD series control system to your required specifications. All engineering phases necessary will be exercised with this elite control system technology. -

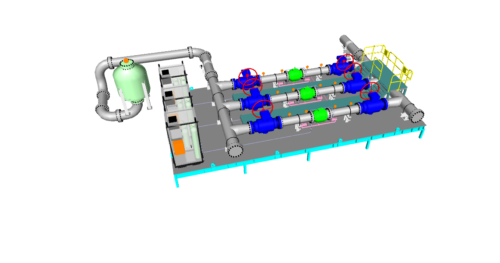

N2X complete surge relief skid system can provide a cost-effective modular solution in lieu of on-site construction. It includes N2X's industry leading NCS nitrogen control system housed in the POD nitrogen control cabinet, surge relief valves, isolation valves, plenums, piping, fitting and platform, all mounted on a skid. Based on the transient hydraulic analysis, the complete sytem is designed to ensure accurate, reliable, and repeatable control accuracy of your pipeline overpressure protection.

N2X complete surge relief skid system can provide a cost-effective modular solution in lieu of on-site construction. It includes N2X's industry leading NCS nitrogen control system housed in the POD nitrogen control cabinet, surge relief valves, isolation valves, plenums, piping, fitting and platform, all mounted on a skid. Based on the transient hydraulic analysis, the complete sytem is designed to ensure accurate, reliable, and repeatable control accuracy of your pipeline overpressure protection. -

The Vahn-Tech Series VT-S Spring-Return Fail-Safe Electric Actuators in addition to the normal function (floating control, on-off control, modulating control) are designed to provide fail-safe positioning of valves and dampers upon loss of power supply. A mechanical spring set is used to position the controlled device to either the fully OPEN or fully CLOSED position without any external power source. For ON-OFF type, a mechanical buffer is employed at the end of the spring stroke in order to reduce the dynamic effects of the spring return system. A clutch-free manual override is available as an option for standard units to provide full-time manual positioning of the valve.

The Vahn-Tech Series VT-S Spring-Return Fail-Safe Electric Actuators in addition to the normal function (floating control, on-off control, modulating control) are designed to provide fail-safe positioning of valves and dampers upon loss of power supply. A mechanical spring set is used to position the controlled device to either the fully OPEN or fully CLOSED position without any external power source. For ON-OFF type, a mechanical buffer is employed at the end of the spring stroke in order to reduce the dynamic effects of the spring return system. A clutch-free manual override is available as an option for standard units to provide full-time manual positioning of the valve. -

The Vahn-Tech Series VT-SX Explosion Proof Spring-Return Fail-Safe Electric Actuators in addition to the normal function (floating control, on-off control, modulating control) are designed to provide fail-safe positioning of valves and dampers upon loss of power supply. A mechanical spring set is used to position the controlled device to either the fully OPEN or fully CLOSED position without any external power source. For ON-OFF type, a mechanical buffer is employed at the end of the spring stroke in order to reduce the dynamic effects of the spring return system. A clutch-free manual override is available as an option for standard units to provide full-time manual positioning of the valve.

The Vahn-Tech Series VT-SX Explosion Proof Spring-Return Fail-Safe Electric Actuators in addition to the normal function (floating control, on-off control, modulating control) are designed to provide fail-safe positioning of valves and dampers upon loss of power supply. A mechanical spring set is used to position the controlled device to either the fully OPEN or fully CLOSED position without any external power source. For ON-OFF type, a mechanical buffer is employed at the end of the spring stroke in order to reduce the dynamic effects of the spring return system. A clutch-free manual override is available as an option for standard units to provide full-time manual positioning of the valve. -

The Valtek GS is a fully integrated valve-actuator-instrumentation package for a continuous process, non-critical flow loop controlled throughout the plant. Engineered from the ground up, the Valtek GS has achieved optimum performance at minimum total cost. It does this by pursuing the simple design philosophy of building an instrumented control valve package that is “everything it needs to be” by providing the breadth and depth of engineered control under the Valtek trusted name.

The Valtek GS is a fully integrated valve-actuator-instrumentation package for a continuous process, non-critical flow loop controlled throughout the plant. Engineered from the ground up, the Valtek GS has achieved optimum performance at minimum total cost. It does this by pursuing the simple design philosophy of building an instrumented control valve package that is “everything it needs to be” by providing the breadth and depth of engineered control under the Valtek trusted name. -

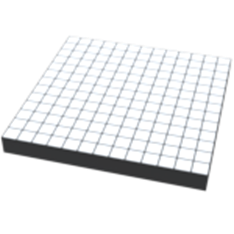

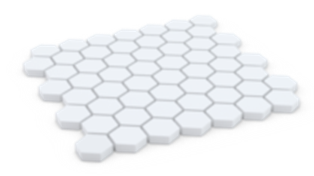

N2X stocks and distributes a full range of high-density, fine-grain, wear-resistant alumina ceramic hex mats (hexagonal tiles). Our CER-1200 grade of alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Wear-resistant hex mats prevent erosion and abrasive wear in conveying and bulk material handling systems. Their flexible design allows for lining of intricate systems including fan blades, chutes, hoppers, and more.

N2X stocks and distributes a full range of high-density, fine-grain, wear-resistant alumina ceramic hex mats (hexagonal tiles). Our CER-1200 grade of alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Wear-resistant hex mats prevent erosion and abrasive wear in conveying and bulk material handling systems. Their flexible design allows for lining of intricate systems including fan blades, chutes, hoppers, and more. -

The Vahn-Tech Series VT-BV-T is an API 6D compliant and monogrammed trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed.

The Vahn-Tech Series VT-BV-T is an API 6D compliant and monogrammed trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed. -

The Vahn-Tech Series VT-BV floating ball valves are designed to provide maximum service life and durability. Designed with extensive safety considerations including provision of locking devices, blow-out proof stems and prevention of misalignment of lever handles provide safe handling in the field. To ensure smooth plant operation, antistatic devices, fire safe seal design and cavity pressure relief features are provided.

The Vahn-Tech Series VT-BV floating ball valves are designed to provide maximum service life and durability. Designed with extensive safety considerations including provision of locking devices, blow-out proof stems and prevention of misalignment of lever handles provide safe handling in the field. To ensure smooth plant operation, antistatic devices, fire safe seal design and cavity pressure relief features are provided. -

The Vahn-Tech Series VT-BV-TE is an API 6D compliant and monogrammed top entry trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed.

The Vahn-Tech Series VT-BV-TE is an API 6D compliant and monogrammed top entry trunnion mounted ball valve available in standard pipeline soft-seated configuration, as well as specialty metal-seated, high-temperature, acid gas and CO2 configurations. Seats designs can be configured as Single Piston Effect (SPE) and Double Piston Effect (DPE), providing verstatility to suit any application requirement for Double Block & Bleed and Double Isolation & Bleed. -

Vahn-Tech Series DOBF is a cost-effective butterfly valve solution for isolation valve applications. Providing lighter weight, smaller face-to-face, and simple quarter-turn rotary movement, a double-offset butterfly valve design is a great solution for zero-leakage isolation relative to ball valves for large sizes. With the eccentric disc designed to reduce the rubbing of the seat it drastically reduces torque requirements for actuation while extending seat life expectancy.

Vahn-Tech Series DOBF is a cost-effective butterfly valve solution for isolation valve applications. Providing lighter weight, smaller face-to-face, and simple quarter-turn rotary movement, a double-offset butterfly valve design is a great solution for zero-leakage isolation relative to ball valves for large sizes. With the eccentric disc designed to reduce the rubbing of the seat it drastically reduces torque requirements for actuation while extending seat life expectancy.