-

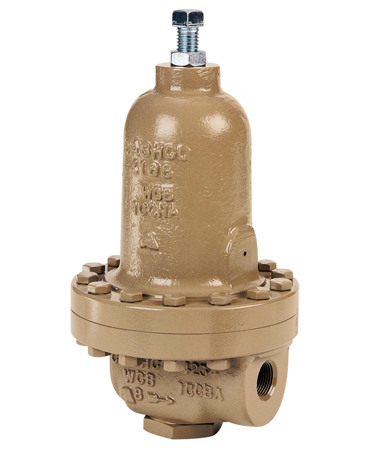

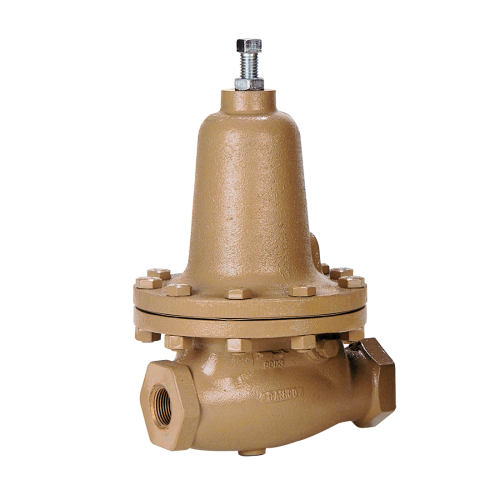

The Model POSR-1 is a pressure-reducing regulator that can be used as a pressure-loaded regulator or as a pilot operated by supplying an external pilot through the main body by a tapped connection. The external pilot valve is supplied from a main valve body-tapped connection. It can handle pressure drops up to 200 psi (13.8 Bar).

The Model POSR-1 is a pressure-reducing regulator that can be used as a pressure-loaded regulator or as a pilot operated by supplying an external pilot through the main body by a tapped connection. The external pilot valve is supplied from a main valve body-tapped connection. It can handle pressure drops up to 200 psi (13.8 Bar). -

Cashco’s Model CA-2 is a compact bronze or stainless steel back pressure regulator used to control inlet pressure levels between atmospheric and 610 psig (42.0 Barg) by relieving excess pressure. This model can be utilized in various services such as liquid recirculation around pumps, cryogenic gas, or liquid or sour service and can be used as a bypass flow regulator in fuel oil systems.

Cashco’s Model CA-2 is a compact bronze or stainless steel back pressure regulator used to control inlet pressure levels between atmospheric and 610 psig (42.0 Barg) by relieving excess pressure. This model can be utilized in various services such as liquid recirculation around pumps, cryogenic gas, or liquid or sour service and can be used as a bypass flow regulator in fuel oil systems. -

The Model BQ is a relief regulator suitable as a back pressure regulator or bypass valve for controlling inlet pressures between 5 and 300 psig (0.34 to 20.7 Barg). This model is designed for controlling a wide range of fluids, including air, inert gases, cryogenic gas or liquids, chemicals, water, fuel oil, and steam.

The Model BQ is a relief regulator suitable as a back pressure regulator or bypass valve for controlling inlet pressures between 5 and 300 psig (0.34 to 20.7 Barg). This model is designed for controlling a wide range of fluids, including air, inert gases, cryogenic gas or liquids, chemicals, water, fuel oil, and steam. -

Cashco’s Model DA5 is a high-capacity self-contained, spring-operated, back-pressure regulator with a top-guided piston cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous services. It can handle both an inlet pressure and pressure drop up to 675 psi.

Cashco’s Model DA5 is a high-capacity self-contained, spring-operated, back-pressure regulator with a top-guided piston cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous services. It can handle both an inlet pressure and pressure drop up to 675 psi. -

The Cashco Model DA1 is a high-performance, spring-operated, flow-to-open, pressure-reducing regulator with internal pressure balancing piston-cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous or liquid services. It can handle an inlet pressure of up to 1480 psi and an outlet pressure of 450 psi in multiple spring ranges.

The Cashco Model DA1 is a high-performance, spring-operated, flow-to-open, pressure-reducing regulator with internal pressure balancing piston-cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous or liquid services. It can handle an inlet pressure of up to 1480 psi and an outlet pressure of 450 psi in multiple spring ranges. -

The Cashco Model DA4 is a high-performance, pressure-loaded diaphragm-type, flow-to-open pressure-reducing regulator. It can handle an inlet pressure of up to 3705 psi and up to 1500 psig pressure drop in multiple spring ranges. The model DA4 can be utilized in a wide variety of applications such as clean fluids, natural gas, air, oil, and corrosive and non-corrosive chemical services. With the pressure-loaded diaphragm and the balanced trim design, the DA4 can meet or exceeds that of the competitive pressure-loaded or pilot-operated designs by providing high flow capacity and high-pressure drop capability.

The Cashco Model DA4 is a high-performance, pressure-loaded diaphragm-type, flow-to-open pressure-reducing regulator. It can handle an inlet pressure of up to 3705 psi and up to 1500 psig pressure drop in multiple spring ranges. The model DA4 can be utilized in a wide variety of applications such as clean fluids, natural gas, air, oil, and corrosive and non-corrosive chemical services. With the pressure-loaded diaphragm and the balanced trim design, the DA4 can meet or exceeds that of the competitive pressure-loaded or pilot-operated designs by providing high flow capacity and high-pressure drop capability. -

The Cashco Model D is a pressure-reducing regulator that is proven to be widely used in different applications including gases, liquids, cryogenics, and steam. One of the main features of the Model D is that it can handle mid-range pressure drops while maintaining good stability. This regulator handles inlet pressures up to 600 psig and outlet pressures up to 250 psig in multiple spring ranges.

The Cashco Model D is a pressure-reducing regulator that is proven to be widely used in different applications including gases, liquids, cryogenics, and steam. One of the main features of the Model D is that it can handle mid-range pressure drops while maintaining good stability. This regulator handles inlet pressures up to 600 psig and outlet pressures up to 250 psig in multiple spring ranges. -

The Ranger QCT is a universal eccentric plug valve with a pneumatic spring diaphragm actuator that can be utilized in many valve applications, most common in steam service. With a different body and trim constructions, it can provide longer life on difficult services. The QCT concept (Quick Change Trim) allows access to the valve body, allowing the use of many valves inserts to meet specific application needs. This feature makes the Ranger QCT very maintenance friendly.

The Ranger QCT is a universal eccentric plug valve with a pneumatic spring diaphragm actuator that can be utilized in many valve applications, most common in steam service. With a different body and trim constructions, it can provide longer life on difficult services. The QCT concept (Quick Change Trim) allows access to the valve body, allowing the use of many valves inserts to meet specific application needs. This feature makes the Ranger QCT very maintenance friendly. -

The Cashco’s Model HP-1+6+S is a heavy-duty, high-pressure reducing differential regulator. The internal trim is of a pressure-balanced design, with the diaphragm having both up and down stops. Inlet pressure may be as high as 3000 psig (207 Barg). Outlet pressure may be as high as 1500 psig (103 Barg). Differential pressure may vary from 15-150 psid (1.0-10.3 Bard). The model HP-1+6+S is most used in gaseous and non-cavitating liquid services.

The Cashco’s Model HP-1+6+S is a heavy-duty, high-pressure reducing differential regulator. The internal trim is of a pressure-balanced design, with the diaphragm having both up and down stops. Inlet pressure may be as high as 3000 psig (207 Barg). Outlet pressure may be as high as 1500 psig (103 Barg). Differential pressure may vary from 15-150 psid (1.0-10.3 Bard). The model HP-1+6+S is most used in gaseous and non-cavitating liquid services. -

Cashco model 1000HP is a high performance self contained pressure reducing regulator. The unique internal design and the straight-through flow path plays a significant role in isolating the diaphragm from fluid velocity effects and increasing capacity and stability at both high or flow rates. The model 1000HP was designed to be utilized in different applications such as steam, industrial gases, air, and water condensate for an inlet pressure of up to 740 psig and outlet pressure of up to 300 psig.

Cashco model 1000HP is a high performance self contained pressure reducing regulator. The unique internal design and the straight-through flow path plays a significant role in isolating the diaphragm from fluid velocity effects and increasing capacity and stability at both high or flow rates. The model 1000HP was designed to be utilized in different applications such as steam, industrial gases, air, and water condensate for an inlet pressure of up to 740 psig and outlet pressure of up to 300 psig. -

Goodwin’s streamlined flow path through an Axial Control Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the seat sealing arrangement. With an annular flow area and an unrestricted, symmetrical, streamlined flow path through the valve, Axial Control Valves have a higher inherent flow capacity compared to conventional globe control valves. Actuation Options Include:

Goodwin’s streamlined flow path through an Axial Control Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the seat sealing arrangement. With an annular flow area and an unrestricted, symmetrical, streamlined flow path through the valve, Axial Control Valves have a higher inherent flow capacity compared to conventional globe control valves. Actuation Options Include:- Manual Operation

- Pneumatic

- Hydraulic

- Electric

- Electro-hydraulic

-

Goodwin’s Axial Isolation Valves can be operated fully open to fully closed or vice-versa in less than 2 seconds. This is compared to a ball valve which usually requires 1 second per inch of bore to do the same operation. The streamlined flow path through an Axial Isolation Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the sealing arrangement. This valve has a bi-directional flow because of the pressure-energized seals, bubble-tight shut-off is achieved in both directions. Actuation Options Include:

Goodwin’s Axial Isolation Valves can be operated fully open to fully closed or vice-versa in less than 2 seconds. This is compared to a ball valve which usually requires 1 second per inch of bore to do the same operation. The streamlined flow path through an Axial Isolation Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the sealing arrangement. This valve has a bi-directional flow because of the pressure-energized seals, bubble-tight shut-off is achieved in both directions. Actuation Options Include:- Manual Operation

- Pneumatic

- Hydraulic

- Electric

- Electro-hydraulic

-

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning.

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning. -

The Model 3300 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3300 can easily be field converted to an end-of-line pressure/vacuum relief vent with the addition of weather hood components or an in-line pressure/vacuum relief with the addition of pipe away body components.

The Model 3300 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3300 can easily be field converted to an end-of-line pressure/vacuum relief vent with the addition of weather hood components or an in-line pressure/vacuum relief with the addition of pipe away body components. -

The Model 3K00 Pressure / Vacuum Vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.

The Model 3K00 Pressure / Vacuum Vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank. -

The Model 1049 offers the best pilot-operated vent technology on the market today. The unit allows for bubble-tight seat leakage until the pilot starts to exhaust. At that time, the vent starts to open and is fully open at 10% overpressure. Unlike non-pilot operated units that require substantial overpressure in order to obtain full lift. On Model 1049, the blowdown is limited, and the valve reseats at the set point, where the non-pilot-operated units will go below the set point in order to reseat.

The Model 1049 offers the best pilot-operated vent technology on the market today. The unit allows for bubble-tight seat leakage until the pilot starts to exhaust. At that time, the vent starts to open and is fully open at 10% overpressure. Unlike non-pilot operated units that require substantial overpressure in order to obtain full lift. On Model 1049, the blowdown is limited, and the valve reseats at the set point, where the non-pilot-operated units will go below the set point in order to reseat.