-

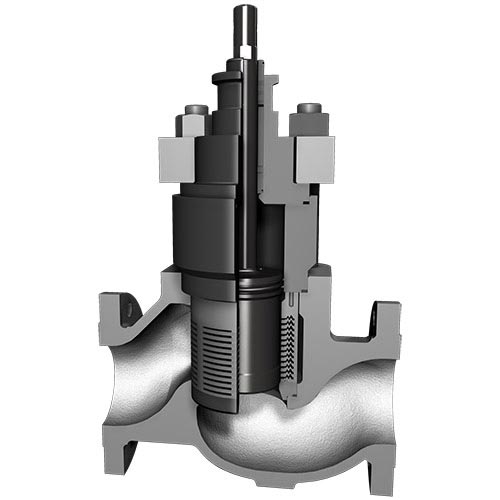

The Kammer TotalFlow (Series 035000 & 335000) is a general service valve portfolio designed to include special configurations. Designed mainly in special materials such as Hastelloy, Alloy 20 or other rare materials, the TotalFlow becomes the solution for your application in any pressure class up to CL2500. For pressure classes up to CL600 it is also available in stainless steel or carbon steel. The series is available as ANSI or DIN and in globe, angle or 3-way valve design. It is a perfect extension to Flowserve‘s FlowTop General Service valve series.

The Kammer TotalFlow (Series 035000 & 335000) is a general service valve portfolio designed to include special configurations. Designed mainly in special materials such as Hastelloy, Alloy 20 or other rare materials, the TotalFlow becomes the solution for your application in any pressure class up to CL2500. For pressure classes up to CL600 it is also available in stainless steel or carbon steel. The series is available as ANSI or DIN and in globe, angle or 3-way valve design. It is a perfect extension to Flowserve‘s FlowTop General Service valve series. -

The NAF Torex, High-Performance butterfly valve is available with either metal-to-metal or soft seats. Due to its unique design and triple offset, it closes extremely tight. It can be used both as a control valve and as a shut-off valve.This valve can be supplied in either wafer or lugged versions. The valves are also available in other materials e.g. Carbon steel, and Titanium, other stainless steel materials and in Fire-safe design.

The NAF Torex, High-Performance butterfly valve is available with either metal-to-metal or soft seats. Due to its unique design and triple offset, it closes extremely tight. It can be used both as a control valve and as a shut-off valve.This valve can be supplied in either wafer or lugged versions. The valves are also available in other materials e.g. Carbon steel, and Titanium, other stainless steel materials and in Fire-safe design. -

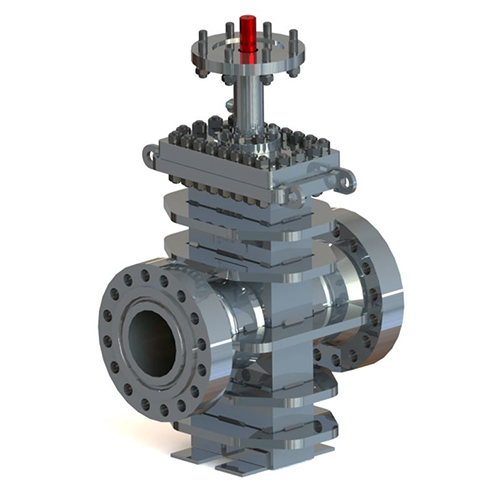

Valbart designed the Trunnion Mounted Control Ball Valve (TMCBV) to operate at high pressures while minimizing the torque needed to operate the valve. The spring-loaded, process energized seats offer tight (Class IV and Class V) shutoff at any pressure. In most cases, the TMCBV's capacity is greater than that of a comparable globe valve. This allows the customer to use a smaller, lighter valve and experience cascading savings. This valve also requires a smaller, less expensive actuator and less expensive pipe supports.

Valbart designed the Trunnion Mounted Control Ball Valve (TMCBV) to operate at high pressures while minimizing the torque needed to operate the valve. The spring-loaded, process energized seats offer tight (Class IV and Class V) shutoff at any pressure. In most cases, the TMCBV's capacity is greater than that of a comparable globe valve. This allows the customer to use a smaller, lighter valve and experience cascading savings. This valve also requires a smaller, less expensive actuator and less expensive pipe supports. -

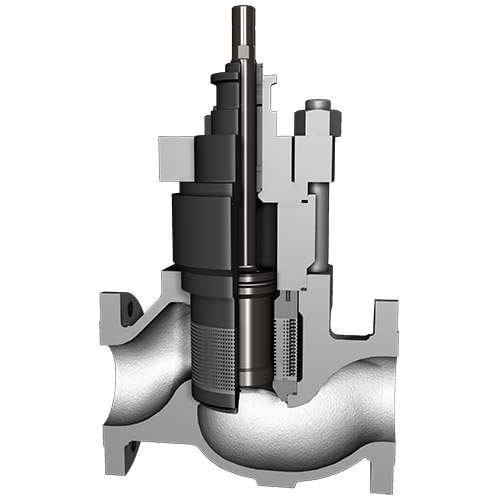

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services.

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services. -

The Valbart TCSGV through conduit slab gate valve is the oil and gas industry's choice for liquid and gas applications requiring reliable, tight shut-off to prevent leakage and minimize losses from process contamination. It is ideal for pipeline applications requiring pigging capability. Its full-bore design features spring-energized seats and a floating slab gate to ensure both low- and high-pressure sealing capabilities. The Valbart TCSGV is manufactured and tested in accordance with API 6D, latest edition. Its design is fully compliant to ASME Section VIII, Division 1. Its design meets API 6D isolation features of block and bleed, double isolation bleed (DIB), double block and bleed, cavity relief, and other requirements commonly specified in the pipeline industry.

The Valbart TCSGV through conduit slab gate valve is the oil and gas industry's choice for liquid and gas applications requiring reliable, tight shut-off to prevent leakage and minimize losses from process contamination. It is ideal for pipeline applications requiring pigging capability. Its full-bore design features spring-energized seats and a floating slab gate to ensure both low- and high-pressure sealing capabilities. The Valbart TCSGV is manufactured and tested in accordance with API 6D, latest edition. Its design is fully compliant to ASME Section VIII, Division 1. Its design meets API 6D isolation features of block and bleed, double isolation bleed (DIB), double block and bleed, cavity relief, and other requirements commonly specified in the pipeline industry. -

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids.

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids. -

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise.

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise. -

The StarPac 3 intelligent control system offers repeatability, accuracy and quick system response time with a small footprint and simple installation. It can stand alone or be integrated into a system, and is available for a variety of applications including oil and gas, chemical, paper, mining, industrial gases and power generation. Unique to the market, StarPac intelligent control systems give users an integrated view of the process at a single point and can improve plant operation at a lower installed cost than conventional control systems. The StarPac 3 builds on previous designs. Upgraded features include explosion-proof housing, USB and infrared interface, updated electronics, stainless steel options and enhanced positioner functions.

The StarPac 3 intelligent control system offers repeatability, accuracy and quick system response time with a small footprint and simple installation. It can stand alone or be integrated into a system, and is available for a variety of applications including oil and gas, chemical, paper, mining, industrial gases and power generation. Unique to the market, StarPac intelligent control systems give users an integrated view of the process at a single point and can improve plant operation at a lower installed cost than conventional control systems. The StarPac 3 builds on previous designs. Upgraded features include explosion-proof housing, USB and infrared interface, updated electronics, stainless steel options and enhanced positioner functions. -

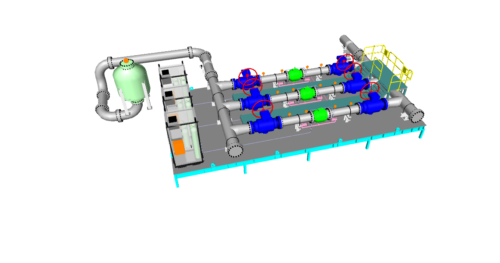

N2X complete surge relief skid system can provide a cost-effective modular solution in lieu of on-site construction. It includes N2X's industry leading NCS nitrogen control system housed in the POD nitrogen control cabinet, surge relief valves, isolation valves, plenums, piping, fitting and platform, all mounted on a skid. Based on the transient hydraulic analysis, the complete sytem is designed to ensure accurate, reliable, and repeatable control accuracy of your pipeline overpressure protection.

N2X complete surge relief skid system can provide a cost-effective modular solution in lieu of on-site construction. It includes N2X's industry leading NCS nitrogen control system housed in the POD nitrogen control cabinet, surge relief valves, isolation valves, plenums, piping, fitting and platform, all mounted on a skid. Based on the transient hydraulic analysis, the complete sytem is designed to ensure accurate, reliable, and repeatable control accuracy of your pipeline overpressure protection. -

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions.

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions. -

The Valtek ShearStream is a segmented, ball control valve that provides exceptional control and rangeability for the process industries. Designed to overcome the problems of harsh, particle entrained processes, ShearStream also provides accurate, reliable control in a broad range of applications, such as chemical, power and petroleum.

The Valtek ShearStream is a segmented, ball control valve that provides exceptional control and rangeability for the process industries. Designed to overcome the problems of harsh, particle entrained processes, ShearStream also provides accurate, reliable control in a broad range of applications, such as chemical, power and petroleum. -

The NAF Setball for Middle Consistency (MC) pulp is a ball sector valve with metal-to-metal seating and combines the best control characteristics of the ball valve and the butterfly valve. It can be used both as control valve and as shut-off valve and is available in flanged version. This valve type is developed for MC-pulp 8-19%. It has an enlarged outlet with one size bigger flange on the outlet to get an excellent flow characteristic for the MC-pulp out of the valve. It is available as standard in 1.4408/CF8M, CG8M and SMO254.

The NAF Setball for Middle Consistency (MC) pulp is a ball sector valve with metal-to-metal seating and combines the best control characteristics of the ball valve and the butterfly valve. It can be used both as control valve and as shut-off valve and is available in flanged version. This valve type is developed for MC-pulp 8-19%. It has an enlarged outlet with one size bigger flange on the outlet to get an excellent flow characteristic for the MC-pulp out of the valve. It is available as standard in 1.4408/CF8M, CG8M and SMO254. -

Setball Segmented Ball Valves are cost-competitive general service valves that offer excellent rangeability and high-flow capacity. NAF Setball can be used in a wide variety of applications and meets the highest demands for control accuracy provided by the equal percentage characteristic and the splined connection between shaft and sector.

Setball Segmented Ball Valves are cost-competitive general service valves that offer excellent rangeability and high-flow capacity. NAF Setball can be used in a wide variety of applications and meets the highest demands for control accuracy provided by the equal percentage characteristic and the splined connection between shaft and sector. -

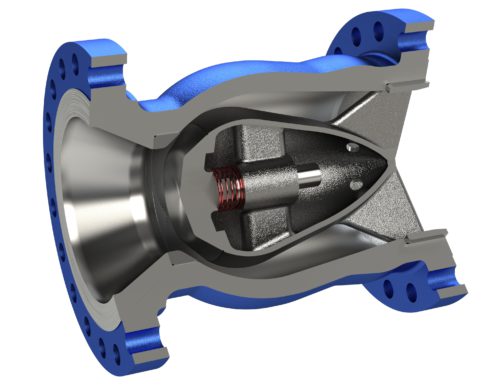

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.