-

The Vahn-Tech Series TOV and TOBF triple offset butterfly valves are designed to meet the critical zero-leakage isolation requirements for industry applications. Split into two primary design categories, floating and fixed seats, there's versatility in the selection to match your process requirements and project economics.

The Vahn-Tech Series TOV and TOBF triple offset butterfly valves are designed to meet the critical zero-leakage isolation requirements for industry applications. Split into two primary design categories, floating and fixed seats, there's versatility in the selection to match your process requirements and project economics. -

Vahn-Tech DC Series knife gate valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with handwheel, or can be automated with pneumatic cylinder or electric actuator for remote operation. The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles. The knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing.

Vahn-Tech DC Series knife gate valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with handwheel, or can be automated with pneumatic cylinder or electric actuator for remote operation. The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles. The knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing. -

Vahn-Tech DK Series knife gate valves are soft sealing shut off valves that are light weight with compact construction, and convenient to install and use. Valves are in full port design and with small flow resistance. When the gate is open, direct current flows between valve and pipeline. Valves can be operated manually with handwheel, or with automatic actuator for remote operation. The cone-shape design of the gates provides strong cutting force. The die-casting rubber seats are with bi-directional sealing. The main advantage of the valves is that when fully open, the medium will not flow into the valve chest, which prevents the pulp from settling in the valve chest and thus reducing the maintenance cost.

Vahn-Tech DK Series knife gate valves are soft sealing shut off valves that are light weight with compact construction, and convenient to install and use. Valves are in full port design and with small flow resistance. When the gate is open, direct current flows between valve and pipeline. Valves can be operated manually with handwheel, or with automatic actuator for remote operation. The cone-shape design of the gates provides strong cutting force. The die-casting rubber seats are with bi-directional sealing. The main advantage of the valves is that when fully open, the medium will not flow into the valve chest, which prevents the pulp from settling in the valve chest and thus reducing the maintenance cost. -

Vahn-Tech DF Series square knife gate valve is mainly used as pneumatic on/off valve for process control in pulp making slurry or sewage treatment. It is particularly suitable to serve as a residue discharger on equipment such as stock cleaners, gravity separators and hydra pulper in the paper making industry.

Vahn-Tech DF Series square knife gate valve is mainly used as pneumatic on/off valve for process control in pulp making slurry or sewage treatment. It is particularly suitable to serve as a residue discharger on equipment such as stock cleaners, gravity separators and hydra pulper in the paper making industry. -

Vahn-Tech DB Series funnel knife gate valve is used in service as a pneumatic residue discharge valve in pulp making, paper making and sewage treatment. This type of valve is well suited for high consistency media containing solids, fiber or residue, serving as a residue discharge valve on stock cleaners, gravity separators or pressurized screens. The "funnel" at the bottom of the collects waste discharged from the valve body during the closing stroke. This greatly reduces the wear between the body and gate, and prolongs the life cycle of the valve.

Vahn-Tech DB Series funnel knife gate valve is used in service as a pneumatic residue discharge valve in pulp making, paper making and sewage treatment. This type of valve is well suited for high consistency media containing solids, fiber or residue, serving as a residue discharge valve on stock cleaners, gravity separators or pressurized screens. The "funnel" at the bottom of the collects waste discharged from the valve body during the closing stroke. This greatly reduces the wear between the body and gate, and prolongs the life cycle of the valve. -

The Flowserve Valtek Mark Six is a globe-style, single-seat, top-entry automatic control valve with a fabricated extension for cold box cryogenic applications to -425°F/‑218°C. Mark Six bodies are constructed of bronze or austenitic stainless steel for high impact strength at low temperature and minimum heat transfer. Mark Six is designed for high flow capacity with a minimum of mass to reduce boil-off on valve cool-down.

The Flowserve Valtek Mark Six is a globe-style, single-seat, top-entry automatic control valve with a fabricated extension for cold box cryogenic applications to -425°F/‑218°C. Mark Six bodies are constructed of bronze or austenitic stainless steel for high impact strength at low temperature and minimum heat transfer. Mark Six is designed for high flow capacity with a minimum of mass to reduce boil-off on valve cool-down. -

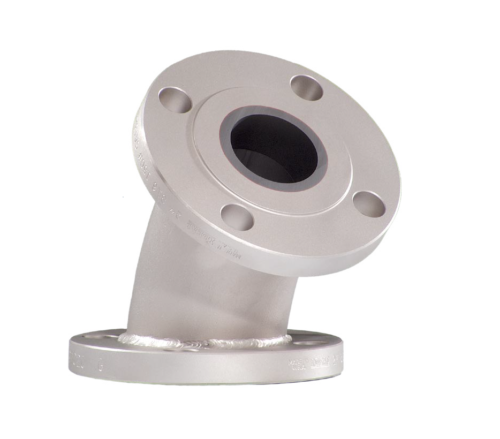

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve.

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve. -

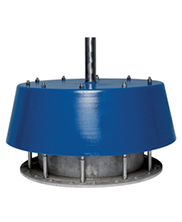

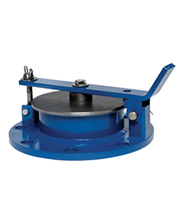

The Model 8700 emergency pressure/vacuum vents provide emergency pressure and vacuum relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks, as well as providing convenient access for tank cleaning, inspection, and repair. The vacuum relief allows the intake of air necessary to maintain the tank pressure within the permissible vacuum limit to avoid damage to the tank.

The Model 8700 emergency pressure/vacuum vents provide emergency pressure and vacuum relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks, as well as providing convenient access for tank cleaning, inspection, and repair. The vacuum relief allows the intake of air necessary to maintain the tank pressure within the permissible vacuum limit to avoid damage to the tank. -

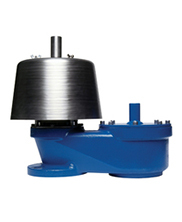

The Model 3700 manhole and emergency pressure vents provide emergency pressure relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks, as well as providing convenient access for tank cleaning, inspection, and repair. Emergency relief valves provide relief from excessive internal pressure, which an abnormal condition, such as ruptured internal heating coils or an external fire may cause.

The Model 3700 manhole and emergency pressure vents provide emergency pressure relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks, as well as providing convenient access for tank cleaning, inspection, and repair. Emergency relief valves provide relief from excessive internal pressure, which an abnormal condition, such as ruptured internal heating coils or an external fire may cause. -

The 8900 Series manway pressure and pressure/vacuum relief vents provide emergency pressure relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks, as well as convenient access for tank cleaning, inspection, and repair. Emergency relief vents provide relief from excessive internal pressure which may be caused by an abnormal condition; such as ruptured internal heating coils, an external fire, a failure of the tank blanketing system, a sudden cooling of the tank or a break in the tank wall.

The 8900 Series manway pressure and pressure/vacuum relief vents provide emergency pressure relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks, as well as convenient access for tank cleaning, inspection, and repair. Emergency relief vents provide relief from excessive internal pressure which may be caused by an abnormal condition; such as ruptured internal heating coils, an external fire, a failure of the tank blanketing system, a sudden cooling of the tank or a break in the tank wall. -

The Model 2100 provides ready access to storage tanks for gauging or obtaining samples. The gauge hatch may also provide additional pressure relief as a supplement for normal or emergency venting. These gauge hatches are intended for use where the fire protection afforded by flame arresters is not considered necessary. Common applications where it is commonly used includes atmospheric and low pressure tanks.

The Model 2100 provides ready access to storage tanks for gauging or obtaining samples. The gauge hatch may also provide additional pressure relief as a supplement for normal or emergency venting. These gauge hatches are intended for use where the fire protection afforded by flame arresters is not considered necessary. Common applications where it is commonly used includes atmospheric and low pressure tanks. -

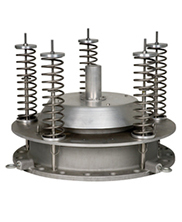

The Model 2199 pressure/vacuum relief hatch provides overpressure relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks. The Model 2199 can also be used as a spring-operated conservation vent and tank hatch that provides convenient access for tank cleaning, inspection, and repair.

The Model 2199 pressure/vacuum relief hatch provides overpressure relief beyond that furnished by the normal pressure vent for atmospheric and low-pressure tanks. The Model 2199 can also be used as a spring-operated conservation vent and tank hatch that provides convenient access for tank cleaning, inspection, and repair. -

The Model 1088 is a valve specifically designed for small tank blanketing applications. It opens and closes automatically as required to maintain a closely controlled blanket pressure. Standard valve material provides added corrosion protection at no additional cost The simple design increases reliability and lowers maintenance cost.

The Model 1088 is a valve specifically designed for small tank blanketing applications. It opens and closes automatically as required to maintain a closely controlled blanket pressure. Standard valve material provides added corrosion protection at no additional cost The simple design increases reliability and lowers maintenance cost. -

The Model 1100 is a stainless steel sanitary vent designed to operate at multiple set points as a breather valve to avoid vacuum or over-pressurization inside a tank or piping system. This unit comes with a true sanitary blanketing connection and is designed so that it can be used with our sanitary blanketing valve; VCI model 1088.

The Model 1100 is a stainless steel sanitary vent designed to operate at multiple set points as a breather valve to avoid vacuum or over-pressurization inside a tank or piping system. This unit comes with a true sanitary blanketing connection and is designed so that it can be used with our sanitary blanketing valve; VCI model 1088. -

The Model 4200 pipe-away conservation vent is part of the Valve Concepts, Inc. modular vent product line. The Model 4200 can easily be converted to a vacuum-only vent or end-of-line pressure/vacuum vent and can either be direct-acting or pilot-operated. Only Valve Concepts, Inc. offers complete modularity throughout its complete vent product line.

The Model 4200 pipe-away conservation vent is part of the Valve Concepts, Inc. modular vent product line. The Model 4200 can easily be converted to a vacuum-only vent or end-of-line pressure/vacuum vent and can either be direct-acting or pilot-operated. Only Valve Concepts, Inc. offers complete modularity throughout its complete vent product line. -

The Model 1049 offers the best pilot-operated vent technology on the market today. The unit allows for bubble-tight seat leakage until the pilot starts to exhaust. At that time, the vent starts to open and is fully open at 10% overpressure. Unlike non-pilot operated units that require substantial overpressure in order to obtain full lift. On Model 1049, the blowdown is limited, and the valve reseats at the set point, where the non-pilot-operated units will go below the set point in order to reseat.

The Model 1049 offers the best pilot-operated vent technology on the market today. The unit allows for bubble-tight seat leakage until the pilot starts to exhaust. At that time, the vent starts to open and is fully open at 10% overpressure. Unlike non-pilot operated units that require substantial overpressure in order to obtain full lift. On Model 1049, the blowdown is limited, and the valve reseats at the set point, where the non-pilot-operated units will go below the set point in order to reseat. -

The Model 3K00 Pressure / Vacuum Vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.

The Model 3K00 Pressure / Vacuum Vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank. -

The Model 3300 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3300 can easily be field converted to an end-of-line pressure/vacuum relief vent with the addition of weather hood components or an in-line pressure/vacuum relief with the addition of pipe away body components.

The Model 3300 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3300 can easily be field converted to an end-of-line pressure/vacuum relief vent with the addition of weather hood components or an in-line pressure/vacuum relief with the addition of pipe away body components. -

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning.

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning. -

Goodwin’s Axial Isolation Valves can be operated fully open to fully closed or vice-versa in less than 2 seconds. This is compared to a ball valve which usually requires 1 second per inch of bore to do the same operation. The streamlined flow path through an Axial Isolation Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the sealing arrangement. This valve has a bi-directional flow because of the pressure-energized seals, bubble-tight shut-off is achieved in both directions. Actuation Options Include:

Goodwin’s Axial Isolation Valves can be operated fully open to fully closed or vice-versa in less than 2 seconds. This is compared to a ball valve which usually requires 1 second per inch of bore to do the same operation. The streamlined flow path through an Axial Isolation Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the sealing arrangement. This valve has a bi-directional flow because of the pressure-energized seals, bubble-tight shut-off is achieved in both directions. Actuation Options Include:- Manual Operation

- Pneumatic

- Hydraulic

- Electric

- Electro-hydraulic

-

Goodwin’s streamlined flow path through an Axial Control Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the seat sealing arrangement. With an annular flow area and an unrestricted, symmetrical, streamlined flow path through the valve, Axial Control Valves have a higher inherent flow capacity compared to conventional globe control valves. Actuation Options Include:

Goodwin’s streamlined flow path through an Axial Control Valve has minimal pressure drop. The flow is directed through the valve to avoid critical sealing areas, promoting the longevity of the seat sealing arrangement. With an annular flow area and an unrestricted, symmetrical, streamlined flow path through the valve, Axial Control Valves have a higher inherent flow capacity compared to conventional globe control valves. Actuation Options Include:- Manual Operation

- Pneumatic

- Hydraulic

- Electric

- Electro-hydraulic