-

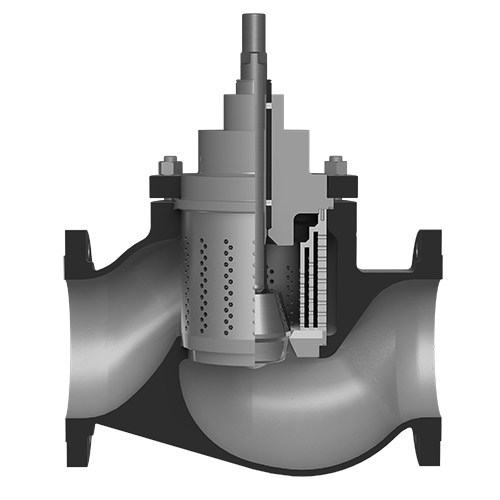

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise.

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise. -

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety.

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety. -

Built from the same basis of design principles as the Mark One but fabricated from bar stock, the Mark Two is an extremely versatile control valve. Due to its constructions, it is available in many different configurations with shorter lead times than conventionally cast valve bodies, even in high-pressure classes or special alloys.

Built from the same basis of design principles as the Mark One but fabricated from bar stock, the Mark Two is an extremely versatile control valve. Due to its constructions, it is available in many different configurations with shorter lead times than conventionally cast valve bodies, even in high-pressure classes or special alloys. -

The Flowserve Valtek Mark Six is a globe-style, single-seat, top-entry automatic control valve with a fabricated extension for cold box cryogenic applications to -425°F/‑218°C. Mark Six bodies are constructed of bronze or austenitic stainless steel for high impact strength at low temperature and minimum heat transfer. Mark Six is designed for high flow capacity with a minimum of mass to reduce boil-off on valve cool-down.

The Flowserve Valtek Mark Six is a globe-style, single-seat, top-entry automatic control valve with a fabricated extension for cold box cryogenic applications to -425°F/‑218°C. Mark Six bodies are constructed of bronze or austenitic stainless steel for high impact strength at low temperature and minimum heat transfer. Mark Six is designed for high flow capacity with a minimum of mass to reduce boil-off on valve cool-down. -

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform.

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform. -

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow.

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow. -

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes.

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes. -

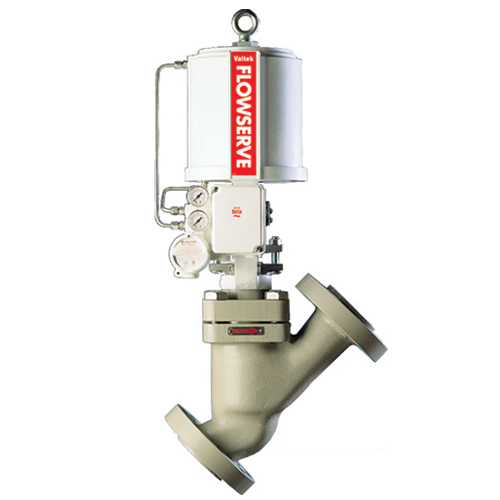

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback -

The Valtek Mark 100 control valve is designed to meet the needs of large applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 100 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes.

The Valtek Mark 100 control valve is designed to meet the needs of large applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 100 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes. -

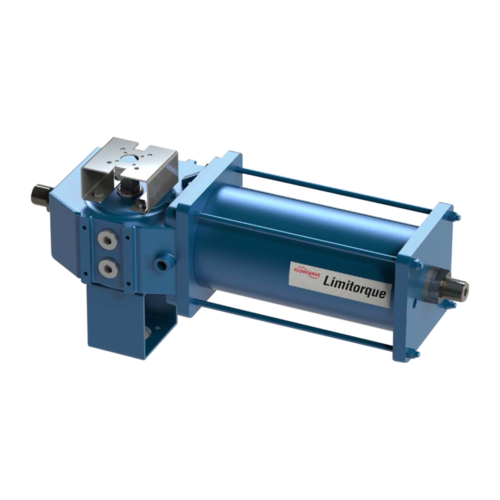

The Limitorque LRP provides durable functionality and prolonged service life through unique features such as piston support rods within the actuator, ensuring that side loads generated by the pistons are transmitted through bearings in the end cap and not the body. This eliminates the need for the body to be used as a loadbearing surface and promotes longer service life. The support rod design of the Limitorque LRP actuator distinguishes it from the standard rack and pinion design and offers reliable operation, performance stability and longer service life.

The Limitorque LRP provides durable functionality and prolonged service life through unique features such as piston support rods within the actuator, ensuring that side loads generated by the pistons are transmitted through bearings in the end cap and not the body. This eliminates the need for the body to be used as a loadbearing surface and promotes longer service life. The support rod design of the Limitorque LRP actuator distinguishes it from the standard rack and pinion design and offers reliable operation, performance stability and longer service life. -

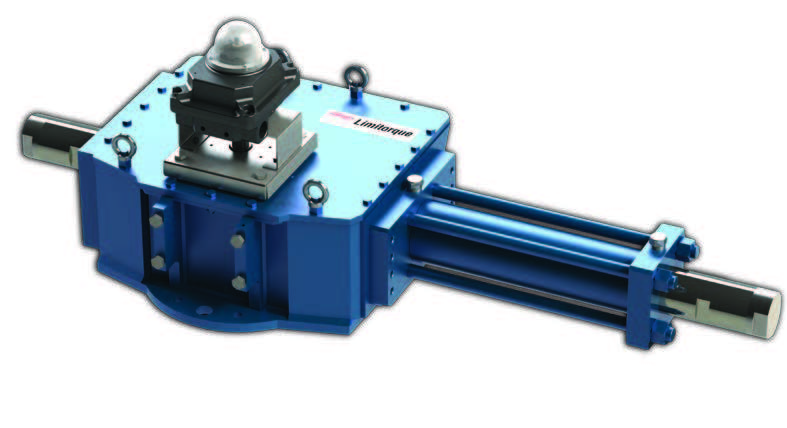

Limitorque's LPS heavy-duty pneumatic scotch yoke actuator is the innovative, reliable choice for on/off, inching and modulating automation applications on quarter-turn medium-to-large sized valves in general and protective services for the oil & gas market. LPS actuators provide up to 550 kNm (405 659 ft-lb) of heavy-duty torque. Enhanced performance is achieved by using a superior Scotch yoke support design that significantly reduces transverse loads. LPS actuators feature modular construction to minimize repair time and initial cost while maximizing process availability.

Limitorque's LPS heavy-duty pneumatic scotch yoke actuator is the innovative, reliable choice for on/off, inching and modulating automation applications on quarter-turn medium-to-large sized valves in general and protective services for the oil & gas market. LPS actuators provide up to 550 kNm (405 659 ft-lb) of heavy-duty torque. Enhanced performance is achieved by using a superior Scotch yoke support design that significantly reduces transverse loads. LPS actuators feature modular construction to minimize repair time and initial cost while maximizing process availability. -

The Limitorque LPC series is a compact pneumatic scotch yoke actuator for on/off, inching and light modulating applications on quarter-turn small-to-medium sized valves in general and protective services for the oil & gas market. Equipment performance and safety standards continue to evolve and increase across the infrastructure industries. These stringent demands are particularly dynamic in oil and gas, where perpetually increasing emphases on personnel safety and equipment uptime is the norm. To more aggressively meet these demands, Flowserve Limitorque is offering the LPC Pneumatic Compact Scotch yoke actuator, specifically designed to meet or exceed the latest and most rigorous of these requirements.

The Limitorque LPC series is a compact pneumatic scotch yoke actuator for on/off, inching and light modulating applications on quarter-turn small-to-medium sized valves in general and protective services for the oil & gas market. Equipment performance and safety standards continue to evolve and increase across the infrastructure industries. These stringent demands are particularly dynamic in oil and gas, where perpetually increasing emphases on personnel safety and equipment uptime is the norm. To more aggressively meet these demands, Flowserve Limitorque is offering the LPC Pneumatic Compact Scotch yoke actuator, specifically designed to meet or exceed the latest and most rigorous of these requirements. -

Many years of experience in the manufacture of lined ball and plug valves and the sophisticated experience of manufacturing excellent reproducible trims for linear valves are combined in this new product. High quality lining materials such as PFA (standard), PVDF, PP, ETFE and FEP as well as PFA antistatic, cover most mediums and applications. The revolutionary PTFE bellows design allows a standard pressure rating of CL150. The increased flow capacity means that the most economical valve can be chosen for the application.

Many years of experience in the manufacture of lined ball and plug valves and the sophisticated experience of manufacturing excellent reproducible trims for linear valves are combined in this new product. High quality lining materials such as PFA (standard), PVDF, PP, ETFE and FEP as well as PFA antistatic, cover most mediums and applications. The revolutionary PTFE bellows design allows a standard pressure rating of CL150. The increased flow capacity means that the most economical valve can be chosen for the application. -

The Limitorque LHS and LHH Hydraulic Scotch Yoke actuator series are designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry. LHS and LHH are ideal where hydraulic motive power is preferred for the operation of quarter-turn valves and for applications requiring a robust heavy duty design, long service life, high-torque and high-speed operation.

The Limitorque LHS and LHH Hydraulic Scotch Yoke actuator series are designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry. LHS and LHH are ideal where hydraulic motive power is preferred for the operation of quarter-turn valves and for applications requiring a robust heavy duty design, long service life, high-torque and high-speed operation. -

The Limitorque LDG Direct Gas powered scotch yoke actuator series is specifically designed to be operated by high pressure natural gas, or any other high pressure pneumatic fluid up to a maximum of 105 barg (1500 psig). LDG actuators are ideal for pipeline applications where no external sources of motive power are present and provide a robust heavy duty design and long service life with industry leading maintenance intervals. This makes them the actuator of choice for installation in remote or unmanned facilities.

The Limitorque LDG Direct Gas powered scotch yoke actuator series is specifically designed to be operated by high pressure natural gas, or any other high pressure pneumatic fluid up to a maximum of 105 barg (1500 psig). LDG actuators are ideal for pipeline applications where no external sources of motive power are present and provide a robust heavy duty design and long service life with industry leading maintenance intervals. This makes them the actuator of choice for installation in remote or unmanned facilities. -

The Kämmer KA & KP Series 2 actuators types P2, P3, P4 and P5 are powerful and compact. By using stainless steel material the actuators have far reaching resistance to corrosion even without a protective coating. Accessories such as positioners, limit switches or solenoid valves etc. can be fitted according to NAMUR. Compact versions with enclosed accessories are also available.

The Kämmer KA & KP Series 2 actuators types P2, P3, P4 and P5 are powerful and compact. By using stainless steel material the actuators have far reaching resistance to corrosion even without a protective coating. Accessories such as positioners, limit switches or solenoid valves etc. can be fitted according to NAMUR. Compact versions with enclosed accessories are also available.