-

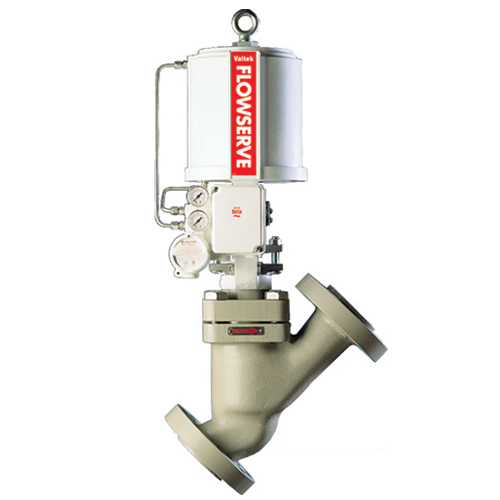

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback -

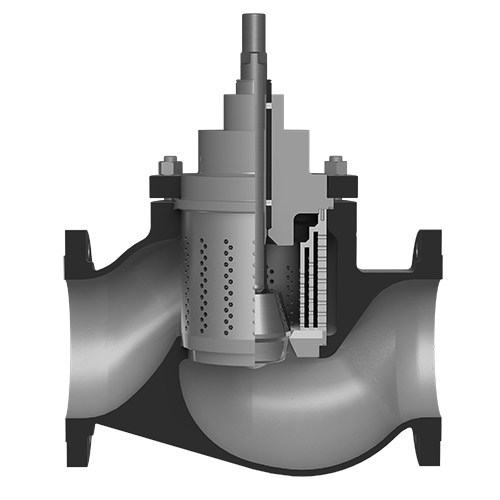

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes.

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes. -

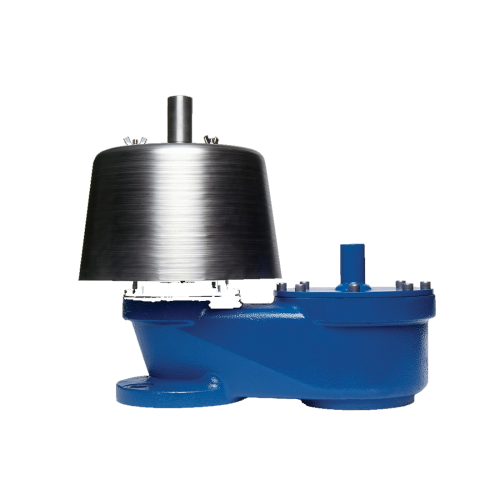

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow.

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow. -

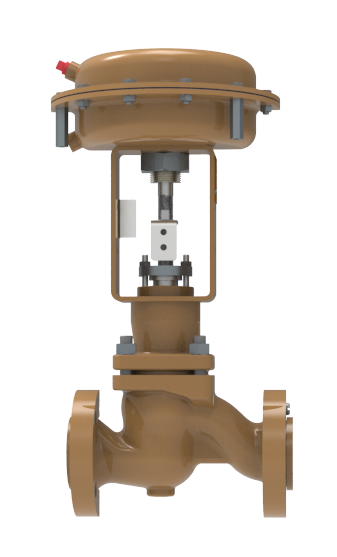

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform.

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform. -

The Flowserve Valtek Mark Six is a globe-style, single-seat, top-entry automatic control valve with a fabricated extension for cold box cryogenic applications to -425°F/‑218°C. Mark Six bodies are constructed of bronze or austenitic stainless steel for high impact strength at low temperature and minimum heat transfer. Mark Six is designed for high flow capacity with a minimum of mass to reduce boil-off on valve cool-down.

The Flowserve Valtek Mark Six is a globe-style, single-seat, top-entry automatic control valve with a fabricated extension for cold box cryogenic applications to -425°F/‑218°C. Mark Six bodies are constructed of bronze or austenitic stainless steel for high impact strength at low temperature and minimum heat transfer. Mark Six is designed for high flow capacity with a minimum of mass to reduce boil-off on valve cool-down. -

Built from the same basis of design principles as the Mark One but fabricated from bar stock, the Mark Two is an extremely versatile control valve. Due to its constructions, it is available in many different configurations with shorter lead times than conventionally cast valve bodies, even in high-pressure classes or special alloys.

Built from the same basis of design principles as the Mark One but fabricated from bar stock, the Mark Two is an extremely versatile control valve. Due to its constructions, it is available in many different configurations with shorter lead times than conventionally cast valve bodies, even in high-pressure classes or special alloys. -

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety.

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety. -

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise.

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise. -

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank. -

The Model 4381 is a stainless steel pressure-reducing regulator designed to handle small to mid-capacity flow rates in general. This model is capable of controlling outlet pressure to a level between 2 and 500 psig (0.14 and 34.5 Barg) with a maximum inlet pressure up to 1500 psig. By having thirteen different trim combinations with the option of a soft or metal seat, the model 4381 can be utilized in different applications such as industrial gases, air, oil, steam, water, and, chemical or cryogenic services.

The Model 4381 is a stainless steel pressure-reducing regulator designed to handle small to mid-capacity flow rates in general. This model is capable of controlling outlet pressure to a level between 2 and 500 psig (0.14 and 34.5 Barg) with a maximum inlet pressure up to 1500 psig. By having thirteen different trim combinations with the option of a soft or metal seat, the model 4381 can be utilized in different applications such as industrial gases, air, oil, steam, water, and, chemical or cryogenic services. -

Pneumatic Control Valve that can be utilized in general service. The body/trim comes in a variety of material selection that includes Ductile Iron ASTM: A395, Carbon Steel (WCB). Model 964 comes in two different seat constructions: metal (Class IV) and a composition seat (Class VI). This model is available in flanged, socket weld, or NPT.

Pneumatic Control Valve that can be utilized in general service. The body/trim comes in a variety of material selection that includes Ductile Iron ASTM: A395, Carbon Steel (WCB). Model 964 comes in two different seat constructions: metal (Class IV) and a composition seat (Class VI). This model is available in flanged, socket weld, or NPT. -

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST, or CW-12MW/Hast. Model 988 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in various end connections such as raised face flanged, socket weld and NPT.

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST, or CW-12MW/Hast. Model 988 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in various end connections such as raised face flanged, socket weld and NPT. -

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST. Model 989 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in flanged.

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST. Model 989 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in flanged. -

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results.

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results. -

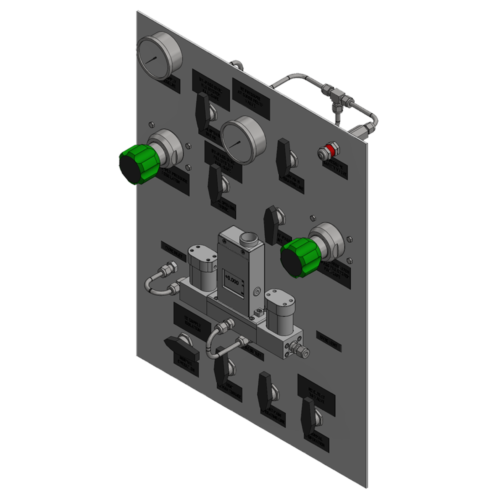

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems.

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems.