-

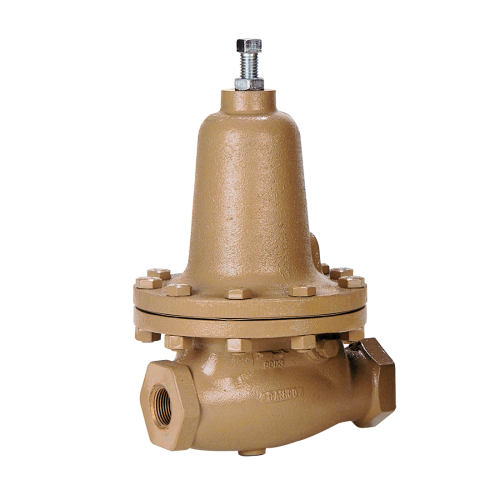

Cashco model 1000HP is a high performance self contained pressure reducing regulator. The unique internal design and the straight-through flow path plays a significant role in isolating the diaphragm from fluid velocity effects and increasing capacity and stability at both high or flow rates. The model 1000HP was designed to be utilized in different applications such as steam, industrial gases, air, and water condensate for an inlet pressure of up to 740 psig and outlet pressure of up to 300 psig.

Cashco model 1000HP is a high performance self contained pressure reducing regulator. The unique internal design and the straight-through flow path plays a significant role in isolating the diaphragm from fluid velocity effects and increasing capacity and stability at both high or flow rates. The model 1000HP was designed to be utilized in different applications such as steam, industrial gases, air, and water condensate for an inlet pressure of up to 740 psig and outlet pressure of up to 300 psig. -

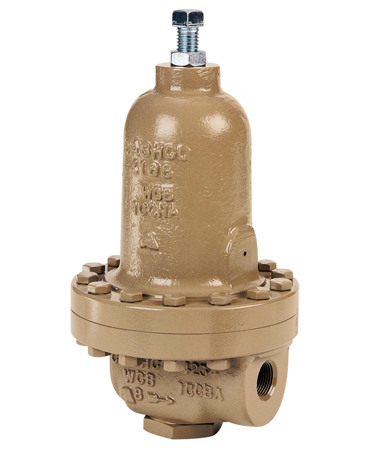

The Cashco’s Model HP-1+6+S is a heavy-duty, high-pressure reducing differential regulator. The internal trim is of a pressure-balanced design, with the diaphragm having both up and down stops. Inlet pressure may be as high as 3000 psig (207 Barg). Outlet pressure may be as high as 1500 psig (103 Barg). Differential pressure may vary from 15-150 psid (1.0-10.3 Bard). The model HP-1+6+S is most used in gaseous and non-cavitating liquid services.

The Cashco’s Model HP-1+6+S is a heavy-duty, high-pressure reducing differential regulator. The internal trim is of a pressure-balanced design, with the diaphragm having both up and down stops. Inlet pressure may be as high as 3000 psig (207 Barg). Outlet pressure may be as high as 1500 psig (103 Barg). Differential pressure may vary from 15-150 psid (1.0-10.3 Bard). The model HP-1+6+S is most used in gaseous and non-cavitating liquid services. -

The Ranger QCT is a universal eccentric plug valve with a pneumatic spring diaphragm actuator that can be utilized in many valve applications, most common in steam service. With a different body and trim constructions, it can provide longer life on difficult services. The QCT concept (Quick Change Trim) allows access to the valve body, allowing the use of many valves inserts to meet specific application needs. This feature makes the Ranger QCT very maintenance friendly.

The Ranger QCT is a universal eccentric plug valve with a pneumatic spring diaphragm actuator that can be utilized in many valve applications, most common in steam service. With a different body and trim constructions, it can provide longer life on difficult services. The QCT concept (Quick Change Trim) allows access to the valve body, allowing the use of many valves inserts to meet specific application needs. This feature makes the Ranger QCT very maintenance friendly. -

The Cashco Model D is a pressure-reducing regulator that is proven to be widely used in different applications including gases, liquids, cryogenics, and steam. One of the main features of the Model D is that it can handle mid-range pressure drops while maintaining good stability. This regulator handles inlet pressures up to 600 psig and outlet pressures up to 250 psig in multiple spring ranges.

The Cashco Model D is a pressure-reducing regulator that is proven to be widely used in different applications including gases, liquids, cryogenics, and steam. One of the main features of the Model D is that it can handle mid-range pressure drops while maintaining good stability. This regulator handles inlet pressures up to 600 psig and outlet pressures up to 250 psig in multiple spring ranges. -

The Cashco Model DA4 is a high-performance, pressure-loaded diaphragm-type, flow-to-open pressure-reducing regulator. It can handle an inlet pressure of up to 3705 psi and up to 1500 psig pressure drop in multiple spring ranges. The model DA4 can be utilized in a wide variety of applications such as clean fluids, natural gas, air, oil, and corrosive and non-corrosive chemical services. With the pressure-loaded diaphragm and the balanced trim design, the DA4 can meet or exceeds that of the competitive pressure-loaded or pilot-operated designs by providing high flow capacity and high-pressure drop capability.

The Cashco Model DA4 is a high-performance, pressure-loaded diaphragm-type, flow-to-open pressure-reducing regulator. It can handle an inlet pressure of up to 3705 psi and up to 1500 psig pressure drop in multiple spring ranges. The model DA4 can be utilized in a wide variety of applications such as clean fluids, natural gas, air, oil, and corrosive and non-corrosive chemical services. With the pressure-loaded diaphragm and the balanced trim design, the DA4 can meet or exceeds that of the competitive pressure-loaded or pilot-operated designs by providing high flow capacity and high-pressure drop capability. -

The Cashco Model DA1 is a high-performance, spring-operated, flow-to-open, pressure-reducing regulator with internal pressure balancing piston-cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous or liquid services. It can handle an inlet pressure of up to 1480 psi and an outlet pressure of 450 psi in multiple spring ranges.

The Cashco Model DA1 is a high-performance, spring-operated, flow-to-open, pressure-reducing regulator with internal pressure balancing piston-cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous or liquid services. It can handle an inlet pressure of up to 1480 psi and an outlet pressure of 450 psi in multiple spring ranges. -

Cashco’s Model DA5 is a high-capacity self-contained, spring-operated, back-pressure regulator with a top-guided piston cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous services. It can handle both an inlet pressure and pressure drop up to 675 psi.

Cashco’s Model DA5 is a high-capacity self-contained, spring-operated, back-pressure regulator with a top-guided piston cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous services. It can handle both an inlet pressure and pressure drop up to 675 psi. -

The Model BQ is a relief regulator suitable as a back pressure regulator or bypass valve for controlling inlet pressures between 5 and 300 psig (0.34 to 20.7 Barg). This model is designed for controlling a wide range of fluids, including air, inert gases, cryogenic gas or liquids, chemicals, water, fuel oil, and steam.

The Model BQ is a relief regulator suitable as a back pressure regulator or bypass valve for controlling inlet pressures between 5 and 300 psig (0.34 to 20.7 Barg). This model is designed for controlling a wide range of fluids, including air, inert gases, cryogenic gas or liquids, chemicals, water, fuel oil, and steam. -

Cashco’s Model CA-2 is a compact bronze or stainless steel back pressure regulator used to control inlet pressure levels between atmospheric and 610 psig (42.0 Barg) by relieving excess pressure. This model can be utilized in various services such as liquid recirculation around pumps, cryogenic gas, or liquid or sour service and can be used as a bypass flow regulator in fuel oil systems.

Cashco’s Model CA-2 is a compact bronze or stainless steel back pressure regulator used to control inlet pressure levels between atmospheric and 610 psig (42.0 Barg) by relieving excess pressure. This model can be utilized in various services such as liquid recirculation around pumps, cryogenic gas, or liquid or sour service and can be used as a bypass flow regulator in fuel oil systems. -

The Model POSR-1 is a pressure-reducing regulator that can be used as a pressure-loaded regulator or as a pilot operated by supplying an external pilot through the main body by a tapped connection. The external pilot valve is supplied from a main valve body-tapped connection. It can handle pressure drops up to 200 psi (13.8 Bar).

The Model POSR-1 is a pressure-reducing regulator that can be used as a pressure-loaded regulator or as a pilot operated by supplying an external pilot through the main body by a tapped connection. The external pilot valve is supplied from a main valve body-tapped connection. It can handle pressure drops up to 200 psi (13.8 Bar). -

The Model P1 is a single stage pressure reducing regulator designed for gases and liquids with inlet pressures up to 3600 psig (248 Barg) and outlet pressure up to 750 psig. It comes in a wide variety of different trim combinations to adapt to different application requirements such as Hydrogen, high-purity gases, and sour services.

The Model P1 is a single stage pressure reducing regulator designed for gases and liquids with inlet pressures up to 3600 psig (248 Barg) and outlet pressure up to 750 psig. It comes in a wide variety of different trim combinations to adapt to different application requirements such as Hydrogen, high-purity gases, and sour services. -

The Model 4381 is a stainless steel pressure-reducing regulator designed to handle small to mid-capacity flow rates in general. This model is capable of controlling outlet pressure to a level between 2 and 500 psig (0.14 and 34.5 Barg) with a maximum inlet pressure up to 1500 psig. By having thirteen different trim combinations with the option of a soft or metal seat, the model 4381 can be utilized in different applications such as industrial gases, air, oil, steam, water, and, chemical or cryogenic services.

The Model 4381 is a stainless steel pressure-reducing regulator designed to handle small to mid-capacity flow rates in general. This model is capable of controlling outlet pressure to a level between 2 and 500 psig (0.14 and 34.5 Barg) with a maximum inlet pressure up to 1500 psig. By having thirteen different trim combinations with the option of a soft or metal seat, the model 4381 can be utilized in different applications such as industrial gases, air, oil, steam, water, and, chemical or cryogenic services. -

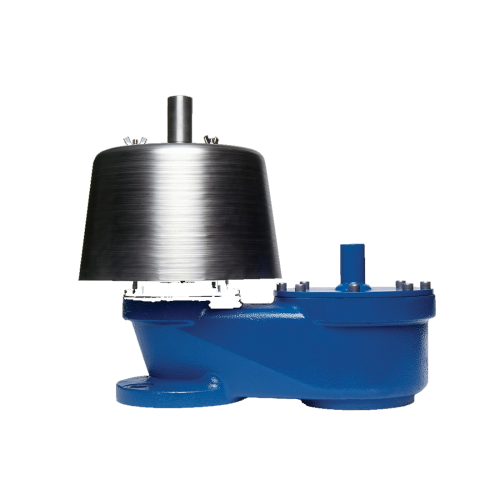

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank. -

Pneumatic Control Valve that can be utilized in general service. The body/trim comes in a variety of material selection that includes Ductile Iron ASTM: A395, Carbon Steel (WCB). Model 964 comes in two different seat constructions: metal (Class IV) and a composition seat (Class VI). This model is available in flanged, socket weld, or NPT.

Pneumatic Control Valve that can be utilized in general service. The body/trim comes in a variety of material selection that includes Ductile Iron ASTM: A395, Carbon Steel (WCB). Model 964 comes in two different seat constructions: metal (Class IV) and a composition seat (Class VI). This model is available in flanged, socket weld, or NPT. -

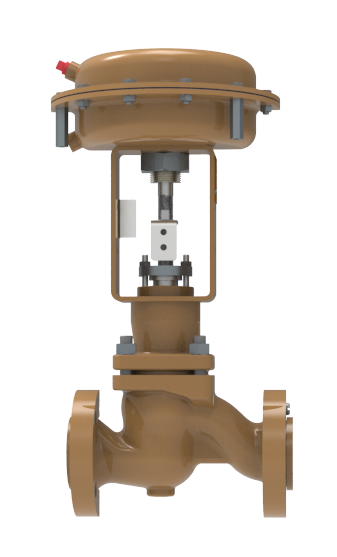

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST, or CW-12MW/Hast. Model 988 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in various end connections such as raised face flanged, socket weld and NPT.

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST, or CW-12MW/Hast. Model 988 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in various end connections such as raised face flanged, socket weld and NPT. -

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST. Model 989 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in flanged.

Pneumatic Control Valve that can be utilized in general and chemical service. The body/trim comes in a variety of material selection that includes: WCB/316L SST, CF3M/316L SST. Model 989 comes in two different seat constructions: metal and (Class IV) and a composition seat (Class VI). This model is available in flanged. -

Goodwin choke valves utilize solid tungsten carbide trim, therefore, minimizing the erosion of critical components, thereby providing long-term reliability of performance in severe service. With the use of “torturous path” technology, it dissipates and controls the high energy, velocity, and turbulence within its trim. Consisting of one or more concentric sleeves with specifically aligned holes in each, the trim provides controlled staged pressure reduction. Actuation Options Include: • Manual Operation • Pneumatic • Hydraulic • Electric • Electro-hydraulic

Goodwin choke valves utilize solid tungsten carbide trim, therefore, minimizing the erosion of critical components, thereby providing long-term reliability of performance in severe service. With the use of “torturous path” technology, it dissipates and controls the high energy, velocity, and turbulence within its trim. Consisting of one or more concentric sleeves with specifically aligned holes in each, the trim provides controlled staged pressure reduction. Actuation Options Include: • Manual Operation • Pneumatic • Hydraulic • Electric • Electro-hydraulic