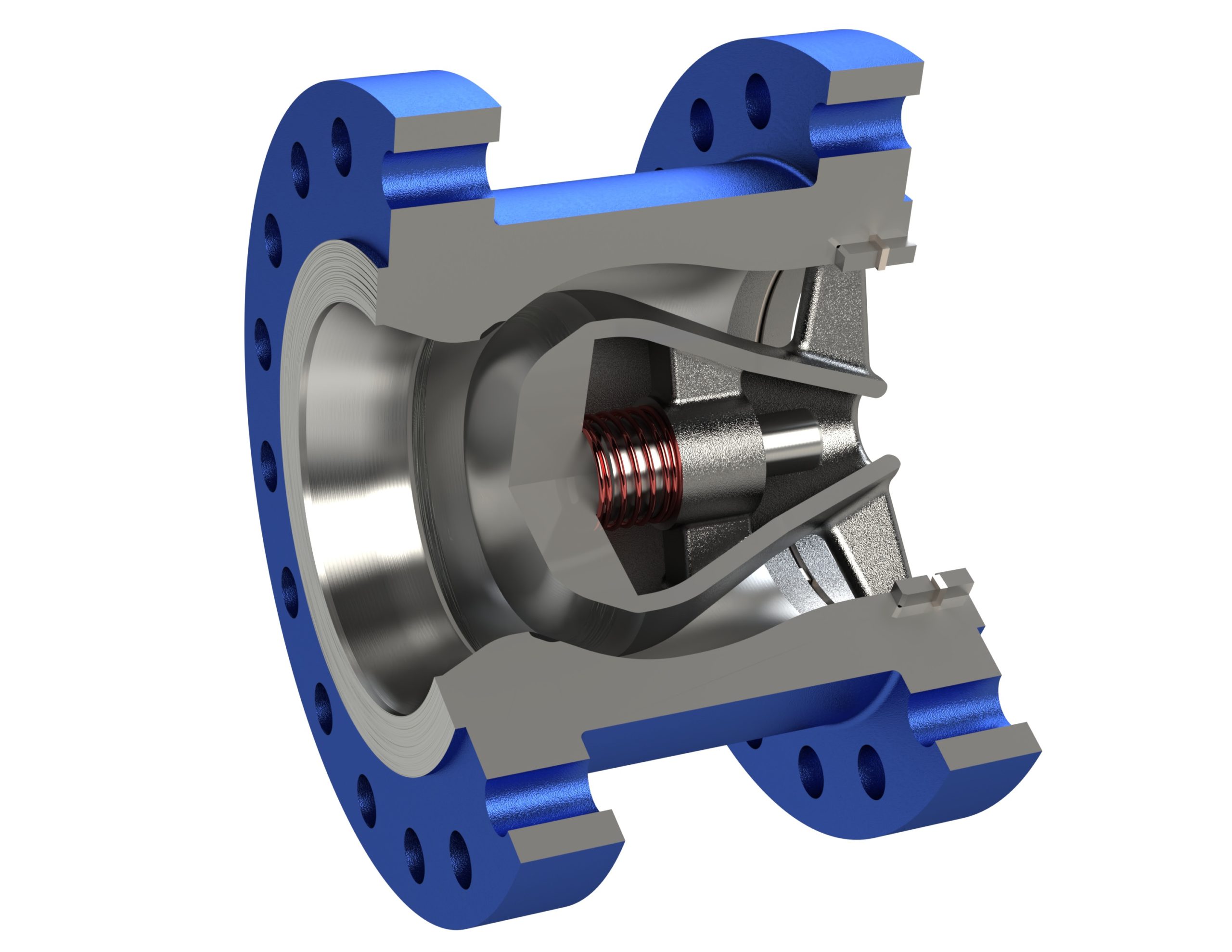

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD)

Additional information

| Valve Size | 1" to 10" |

|---|---|

| Pressure Class Standard | ASME B16.34, API 6A |

| Pressure Class Range | Class 150, 300, 600, 900, 1500, 2500, 4500; API 2000, 3000, 5000, 10000, 15000, 20000 |

| Body | One-Piece Body |

| End Connections | Flanged, Hub-End, Butt-Weld, Socket-Weld, Threaded |

| Face-to-Face Standard | Manufacturer Standard |

| Disc Type | Solid |

| Guiding | Centre |

| Seating | Metal-to-Metal |

| Flow | Axial |

| Type | Non-Slam Anti-Surge |

| Media Application | Liquids, Gases |

| Shut-Off Classification | API 598, ISO 5208 Rate E |

Features & Benefits

- The streamlined internals of the axial check valve range allow for a turbulence free flow path around the disc

- The high capacity, smooth flow path results in low pressure drop across all of the axial type valves

- Noreva axial check valve designs use no soft parts and are therefore inherently fire-safe

- There are no wearing parts, for clean services, making it maintenance free

- The springs are sized according to the flow rates to ensure that the valves are in the fully open position during normal use

- The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimizing pressure drop across the valve

- A short stroke length provides the quick response required by a non-slam check valve

- Low weight discs, short stroke lengths and spring assistance combine to ensure that it responds quickest to change in flow direction

- The fast response ensures reverse velocity cannot build up to a level that can damage pumps, pipes or related equipment

- Pressure surges can occur when a valve is closed against a moving body of fluid, the quick closure results in a considerably lower pressure peak

Standards & Certifications

| Certifications | Canadian Registration Number (CRN) |

|---|---|

| ANSI NSF 61 – Drinking Water System Components – Health Effects | |

| PED 2014/68/EU CE Mark | |

| Design Standards | ASME B16.47 – Large Diameter Steel Flanges |

| ASME B16.5 – Pipe Flanges & Flanged Fittings | |

| ASME B16.9 – Factory-Made Wrought Buttwelding Fittings | |

| ASME B16.10 – Face to Face & End Dimenions of Valves | |

| ASME B16.11 – Forged Fittings, Socket-Welding & Threaded | |

| ASME B16.25 – Buttwelding Ends | |

| ASME B16.34 – Valve Flanged, Threaded, and Welding End | |

| ASME SA Materials | |

| ASTM A Materials | |

| Quality | IS0 9001:2015 |