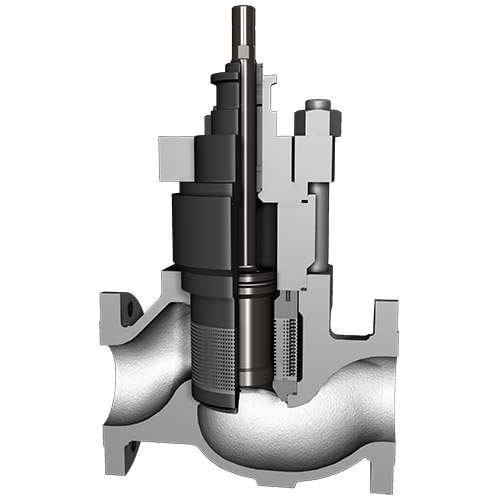

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise.

Additional information

| Function | Gaseous Noise Reduction |

|---|---|

| Pressure Stages | 6 to 20 |

| Cv Range | 4 to 4000 |

| Noise Attenuation | 40 dBa |

| Trim Design | Stacked Discs |

| Solids Capable | No |

| Materials | Alloy |

| Base Valve | Flowserve Valtek Mark Series |

| Valve Size | 3" to 36" |

| Pressure Class Standard | ASME B16.34 |

| Pressure Class Range | Class 150, 300, 600, 900, 1500, 2500, 4500 |

Features & Benefits

- Noise attenuation of up to 40 dBa

- Stealth is the most efficient high pressure drop noise attenuation trim ever developed

- Stealth uses laser-cut discs to create stacked disc seat retainers

- The cuts in the discs form channels for the fluid to pass through

- Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise

- WaveCracker technology provides extra noise attenuation without creating extra pressure drops in the valve

- Trim exit flow paths on the Stealth are angled to direct the flow to the valve exit