-

The Logix™ 3200MD+ Digital HART Positioner from Flowserve utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3200MD+ can be easily configured using the local buttons or the ValveSight™ DTM. The Logix 3200MD+ is designed to withstand severe environments; it is equipped with over 100 helpful warning alarms that can warn against potential failure of the valve, actuator and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues.

The Logix™ 3200MD+ Digital HART Positioner from Flowserve utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3200MD+ can be easily configured using the local buttons or the ValveSight™ DTM. The Logix 3200MD+ is designed to withstand severe environments; it is equipped with over 100 helpful warning alarms that can warn against potential failure of the valve, actuator and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues. -

The Flowserve Logix 3400MD Digital Foundation Fieldbus positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3400MD can be easily configured using the local buttons or the ValveSight DTM. Logix 3400MD has a complete diagnostics package that can alert the user to developing conditions that may cause unnecessary upset conditions in the plant.

The Flowserve Logix 3400MD Digital Foundation Fieldbus positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3400MD can be easily configured using the local buttons or the ValveSight DTM. Logix 3400MD has a complete diagnostics package that can alert the user to developing conditions that may cause unnecessary upset conditions in the plant. -

Compatible with linear and rotary valves and actuators, Logix 3800 digital positioner delivers high reliability in tough environments. It provides unparalleled modularity and versatility within a single unit. Its ability to handle double- or single-acting, linear and rotary applications reduces inventory and operating costs. Installation is simplified with an innovative, one-button quick calibration feature.

Compatible with linear and rotary valves and actuators, Logix 3800 digital positioner delivers high reliability in tough environments. It provides unparalleled modularity and versatility within a single unit. Its ability to handle double- or single-acting, linear and rotary applications reduces inventory and operating costs. Installation is simplified with an innovative, one-button quick calibration feature. -

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs.

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs. -

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning.

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning. -

The Logix 520MD Series digital positioner combines superior positioning and tuning functions with convenient setup and powerful diagnostic tools. The Logix 520MD positioner uses a multi-variable gain tuning algorithm which allows the positioner to make large step changes with minimal overshoot while achieving the resolution to respond to very small step changes. The Auto-tune procedure cycles the actuator to produce a measured response and selects gain values that provide appropriate actuator performance. The Auto-tune function includes a gain modifier selector that can be used to increase or decrease the calculated gain in order to achieve optimal performance. Easy DIP switch configuration for tuning mode and other common settings. For custom settings, tuning sets can be modified with a handheld or with ValveSight software, to accommodate a wide range of actuator sizes and types.

The Logix 520MD Series digital positioner combines superior positioning and tuning functions with convenient setup and powerful diagnostic tools. The Logix 520MD positioner uses a multi-variable gain tuning algorithm which allows the positioner to make large step changes with minimal overshoot while achieving the resolution to respond to very small step changes. The Auto-tune procedure cycles the actuator to produce a measured response and selects gain values that provide appropriate actuator performance. The Auto-tune function includes a gain modifier selector that can be used to increase or decrease the calculated gain in order to achieve optimal performance. Easy DIP switch configuration for tuning mode and other common settings. For custom settings, tuning sets can be modified with a handheld or with ValveSight software, to accommodate a wide range of actuator sizes and types. -

The Flowserve Logix 520MD+ Digital HART Positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 520MD+ Positioner is designed to withstand severe environments; it is equipped with over 130 helpful warning alarms that can warn against potential failure of the valve, actuator, and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues.

The Flowserve Logix 520MD+ Digital HART Positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 520MD+ Positioner is designed to withstand severe environments; it is equipped with over 130 helpful warning alarms that can warn against potential failure of the valve, actuator, and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues. -

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments.

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments. -

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction.

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction. -

By using an extended bonnet, the packing, gaskets and seals of ColdFlow valves are protected from cryogenic temperatures, thus ensuring their sealing properties. Optional special gaskets and packing can be used to operate at temperatures as low as -69 °C. Depending on the application, Flowserve cryogenic valves are available with a top entry design for the easy maintenance of valves located in a cold box or with a simple extended bonnet attached to the valve body.

By using an extended bonnet, the packing, gaskets and seals of ColdFlow valves are protected from cryogenic temperatures, thus ensuring their sealing properties. Optional special gaskets and packing can be used to operate at temperatures as low as -69 °C. Depending on the application, Flowserve cryogenic valves are available with a top entry design for the easy maintenance of valves located in a cold box or with a simple extended bonnet attached to the valve body. -

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief.

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief. -

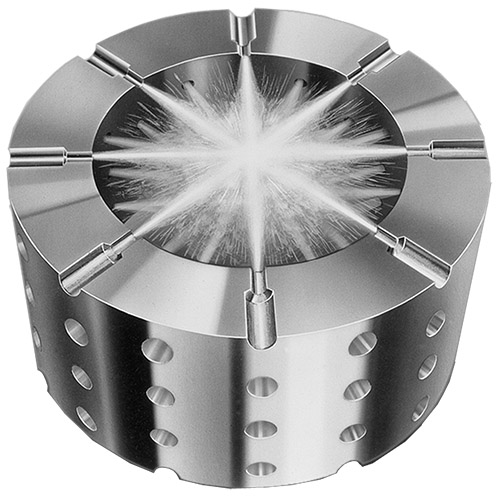

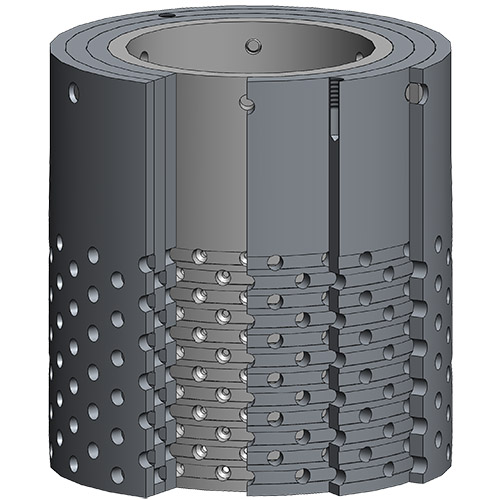

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services.

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services. -

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators.

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators. -

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve.

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve.