-

The Logix™ 3200MD+ Digital HART Positioner from Flowserve utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3200MD+ can be easily configured using the local buttons or the ValveSight™ DTM. The Logix 3200MD+ is designed to withstand severe environments; it is equipped with over 100 helpful warning alarms that can warn against potential failure of the valve, actuator and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues.

The Logix™ 3200MD+ Digital HART Positioner from Flowserve utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3200MD+ can be easily configured using the local buttons or the ValveSight™ DTM. The Logix 3200MD+ is designed to withstand severe environments; it is equipped with over 100 helpful warning alarms that can warn against potential failure of the valve, actuator and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues. -

The Flowserve Logix 3400MD Digital Foundation Fieldbus positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3400MD can be easily configured using the local buttons or the ValveSight DTM. Logix 3400MD has a complete diagnostics package that can alert the user to developing conditions that may cause unnecessary upset conditions in the plant.

The Flowserve Logix 3400MD Digital Foundation Fieldbus positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 3400MD can be easily configured using the local buttons or the ValveSight DTM. Logix 3400MD has a complete diagnostics package that can alert the user to developing conditions that may cause unnecessary upset conditions in the plant. -

Compatible with linear and rotary valves and actuators, Logix 3800 digital positioner delivers high reliability in tough environments. It provides unparalleled modularity and versatility within a single unit. Its ability to handle double- or single-acting, linear and rotary applications reduces inventory and operating costs. Installation is simplified with an innovative, one-button quick calibration feature.

Compatible with linear and rotary valves and actuators, Logix 3800 digital positioner delivers high reliability in tough environments. It provides unparalleled modularity and versatility within a single unit. Its ability to handle double- or single-acting, linear and rotary applications reduces inventory and operating costs. Installation is simplified with an innovative, one-button quick calibration feature. -

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs.

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs. -

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning.

The Flowserve Logix Zero-Bleed automation package is a comprehensive solution designed to help eliminate emissions in accordance to industry regulations governing steady-state bleed from pneumatic devices. The 3800zb control unit, which serves as the heart of the Zero Bleed Automation Package, brings simplicity and effectiveness to process control. It leverages the advanced features of the 3800 Smart Positioner device and integrates a zero-bleed system to achieve emissions reduction during steady-state positioning. -

The Vahn-Tech Series 4X4 packs more than double the torque of conventional rack and pinion actuators thanks to its four pistons generating torque around a centrally located pinion. With more pistons in the actuator, this allows the actuator being more compact with size reduced by more than 30% compared to double piston actuator of the same torque. With four small cylinders each located on one of four sides of the unit and at a given air pressure, the 4x4 produces the same torque output as double piston models using smaller diameter pistons and a narrower pinion. The narrower pinion allows the pistons to travel shorter distances so that they can move faster from one position to the next.

The Vahn-Tech Series 4X4 packs more than double the torque of conventional rack and pinion actuators thanks to its four pistons generating torque around a centrally located pinion. With more pistons in the actuator, this allows the actuator being more compact with size reduced by more than 30% compared to double piston actuator of the same torque. With four small cylinders each located on one of four sides of the unit and at a given air pressure, the 4x4 produces the same torque output as double piston models using smaller diameter pistons and a narrower pinion. The narrower pinion allows the pistons to travel shorter distances so that they can move faster from one position to the next. -

The Logix 520MD Series digital positioner combines superior positioning and tuning functions with convenient setup and powerful diagnostic tools. The Logix 520MD positioner uses a multi-variable gain tuning algorithm which allows the positioner to make large step changes with minimal overshoot while achieving the resolution to respond to very small step changes. The Auto-tune procedure cycles the actuator to produce a measured response and selects gain values that provide appropriate actuator performance. The Auto-tune function includes a gain modifier selector that can be used to increase or decrease the calculated gain in order to achieve optimal performance. Easy DIP switch configuration for tuning mode and other common settings. For custom settings, tuning sets can be modified with a handheld or with ValveSight software, to accommodate a wide range of actuator sizes and types.

The Logix 520MD Series digital positioner combines superior positioning and tuning functions with convenient setup and powerful diagnostic tools. The Logix 520MD positioner uses a multi-variable gain tuning algorithm which allows the positioner to make large step changes with minimal overshoot while achieving the resolution to respond to very small step changes. The Auto-tune procedure cycles the actuator to produce a measured response and selects gain values that provide appropriate actuator performance. The Auto-tune function includes a gain modifier selector that can be used to increase or decrease the calculated gain in order to achieve optimal performance. Easy DIP switch configuration for tuning mode and other common settings. For custom settings, tuning sets can be modified with a handheld or with ValveSight software, to accommodate a wide range of actuator sizes and types. -

The Flowserve Logix 520MD+ Digital HART Positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 520MD+ Positioner is designed to withstand severe environments; it is equipped with over 130 helpful warning alarms that can warn against potential failure of the valve, actuator, and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues.

The Flowserve Logix 520MD+ Digital HART Positioner utilizes state-of-the-art piezo technology to provide superior performance and reliability. The Logix 520MD+ Positioner is designed to withstand severe environments; it is equipped with over 130 helpful warning alarms that can warn against potential failure of the valve, actuator, and positioner. When utilized with the ValveSight DTM Software many diagnostic tools are available to quickly diagnose problems and potential issues. -

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments.

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments. -

The DFS series scotch and Yoke Pneumatic Actuators are heavy-duty actuators for operating large diameter ball valves, butterfly valves, plug valves and other 90˚ rotating mechanism. Available with two yoke deigns namely symmetrical design and canted yoke design. Cylinder blocks are plated with hard chromium to increase the service life of the actuators. The piston rod and guide block connection superior surface finish and the self-lubricating bearings maximize the input energy transfer directly to the valve stem and ensure reliable operation over the service life of the actuator. Can be supplied with the complete line of controls and monitoring accessories, including hand wheel, hydraulic manual override, limit switches, solenoid valves, positioners and other control accessories.

The DFS series scotch and Yoke Pneumatic Actuators are heavy-duty actuators for operating large diameter ball valves, butterfly valves, plug valves and other 90˚ rotating mechanism. Available with two yoke deigns namely symmetrical design and canted yoke design. Cylinder blocks are plated with hard chromium to increase the service life of the actuators. The piston rod and guide block connection superior surface finish and the self-lubricating bearings maximize the input energy transfer directly to the valve stem and ensure reliable operation over the service life of the actuator. Can be supplied with the complete line of controls and monitoring accessories, including hand wheel, hydraulic manual override, limit switches, solenoid valves, positioners and other control accessories. -

The Vahn-Tech Series DFS is an economic rack and pinion style pnuematic actuator, with both captured coil spring-return and double-acting configurations. With standardized accessory (VDI/VDE 3845) and valve (ISO 5211) mounting pads, packaging with Vahn-Tech and third-party valves and accessories is simplified and easy.

The Vahn-Tech Series DFS is an economic rack and pinion style pnuematic actuator, with both captured coil spring-return and double-acting configurations. With standardized accessory (VDI/VDE 3845) and valve (ISO 5211) mounting pads, packaging with Vahn-Tech and third-party valves and accessories is simplified and easy. -

The Kämmer KA & KP Series 2 actuators types P2, P3, P4 and P5 are powerful and compact. By using stainless steel material the actuators have far reaching resistance to corrosion even without a protective coating. Accessories such as positioners, limit switches or solenoid valves etc. can be fitted according to NAMUR. Compact versions with enclosed accessories are also available.

The Kämmer KA & KP Series 2 actuators types P2, P3, P4 and P5 are powerful and compact. By using stainless steel material the actuators have far reaching resistance to corrosion even without a protective coating. Accessories such as positioners, limit switches or solenoid valves etc. can be fitted according to NAMUR. Compact versions with enclosed accessories are also available. -

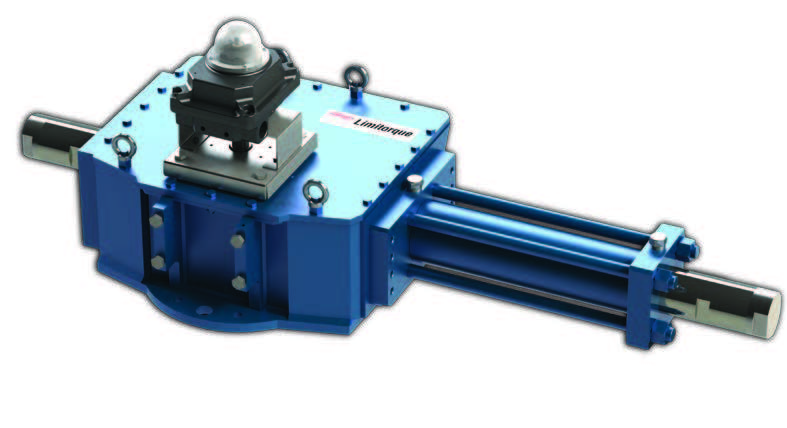

The Limitorque LDG Direct Gas powered scotch yoke actuator series is specifically designed to be operated by high pressure natural gas, or any other high pressure pneumatic fluid up to a maximum of 105 barg (1500 psig). LDG actuators are ideal for pipeline applications where no external sources of motive power are present and provide a robust heavy duty design and long service life with industry leading maintenance intervals. This makes them the actuator of choice for installation in remote or unmanned facilities.

The Limitorque LDG Direct Gas powered scotch yoke actuator series is specifically designed to be operated by high pressure natural gas, or any other high pressure pneumatic fluid up to a maximum of 105 barg (1500 psig). LDG actuators are ideal for pipeline applications where no external sources of motive power are present and provide a robust heavy duty design and long service life with industry leading maintenance intervals. This makes them the actuator of choice for installation in remote or unmanned facilities. -

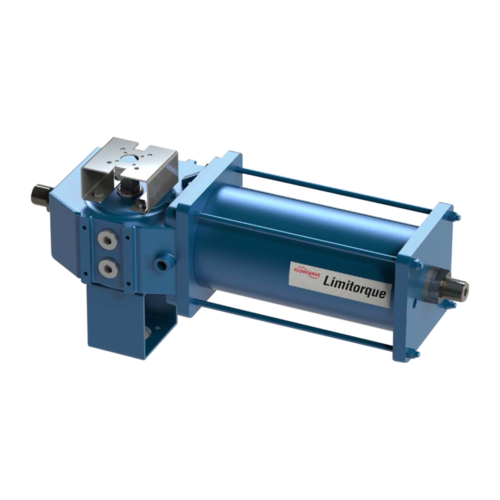

The Limitorque LHS and LHH Hydraulic Scotch Yoke actuator series are designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry. LHS and LHH are ideal where hydraulic motive power is preferred for the operation of quarter-turn valves and for applications requiring a robust heavy duty design, long service life, high-torque and high-speed operation.

The Limitorque LHS and LHH Hydraulic Scotch Yoke actuator series are designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry. LHS and LHH are ideal where hydraulic motive power is preferred for the operation of quarter-turn valves and for applications requiring a robust heavy duty design, long service life, high-torque and high-speed operation. -

The Limitorque LPC series is a compact pneumatic scotch yoke actuator for on/off, inching and light modulating applications on quarter-turn small-to-medium sized valves in general and protective services for the oil & gas market. Equipment performance and safety standards continue to evolve and increase across the infrastructure industries. These stringent demands are particularly dynamic in oil and gas, where perpetually increasing emphases on personnel safety and equipment uptime is the norm. To more aggressively meet these demands, Flowserve Limitorque is offering the LPC Pneumatic Compact Scotch yoke actuator, specifically designed to meet or exceed the latest and most rigorous of these requirements.

The Limitorque LPC series is a compact pneumatic scotch yoke actuator for on/off, inching and light modulating applications on quarter-turn small-to-medium sized valves in general and protective services for the oil & gas market. Equipment performance and safety standards continue to evolve and increase across the infrastructure industries. These stringent demands are particularly dynamic in oil and gas, where perpetually increasing emphases on personnel safety and equipment uptime is the norm. To more aggressively meet these demands, Flowserve Limitorque is offering the LPC Pneumatic Compact Scotch yoke actuator, specifically designed to meet or exceed the latest and most rigorous of these requirements. -

Limitorque's LPS heavy-duty pneumatic scotch yoke actuator is the innovative, reliable choice for on/off, inching and modulating automation applications on quarter-turn medium-to-large sized valves in general and protective services for the oil & gas market. LPS actuators provide up to 550 kNm (405 659 ft-lb) of heavy-duty torque. Enhanced performance is achieved by using a superior Scotch yoke support design that significantly reduces transverse loads. LPS actuators feature modular construction to minimize repair time and initial cost while maximizing process availability.

Limitorque's LPS heavy-duty pneumatic scotch yoke actuator is the innovative, reliable choice for on/off, inching and modulating automation applications on quarter-turn medium-to-large sized valves in general and protective services for the oil & gas market. LPS actuators provide up to 550 kNm (405 659 ft-lb) of heavy-duty torque. Enhanced performance is achieved by using a superior Scotch yoke support design that significantly reduces transverse loads. LPS actuators feature modular construction to minimize repair time and initial cost while maximizing process availability.