-

By using an extended bonnet, the packing, gaskets and seals of ColdFlow valves are protected from cryogenic temperatures, thus ensuring their sealing properties. Optional special gaskets and packing can be used to operate at temperatures as low as -69 °C. Depending on the application, Flowserve cryogenic valves are available with a top entry design for the easy maintenance of valves located in a cold box or with a simple extended bonnet attached to the valve body.

By using an extended bonnet, the packing, gaskets and seals of ColdFlow valves are protected from cryogenic temperatures, thus ensuring their sealing properties. Optional special gaskets and packing can be used to operate at temperatures as low as -69 °C. Depending on the application, Flowserve cryogenic valves are available with a top entry design for the easy maintenance of valves located in a cold box or with a simple extended bonnet attached to the valve body. -

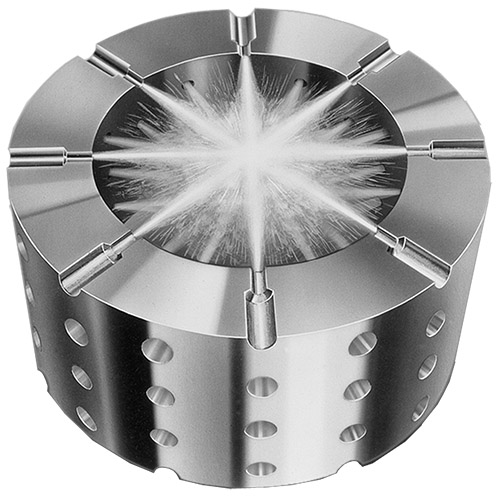

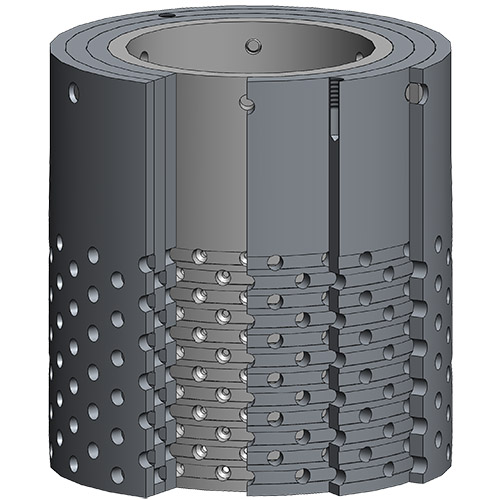

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services.

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services. -

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve.

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve. -

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance.

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance. -

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications.

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications. -

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated.

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated. -

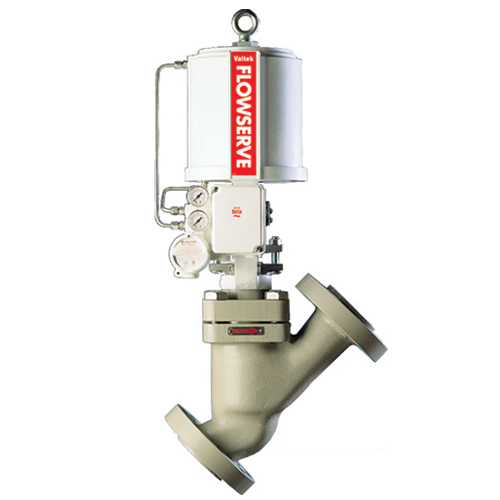

The Valtek FlowTop GS control valve (types V746 and V748) improves the reliability and uptime of production processes while minimizing operating and maintenance costs. Designed for general service applications, the FlowTop GS globe valve is a competitively priced, fully integrated valve-actuator-instrumentation package for continuous process flow loop control throughout the plant.

The Valtek FlowTop GS control valve (types V746 and V748) improves the reliability and uptime of production processes while minimizing operating and maintenance costs. Designed for general service applications, the FlowTop GS globe valve is a competitively priced, fully integrated valve-actuator-instrumentation package for continuous process flow loop control throughout the plant. -

The Valtek GS is a fully integrated valve-actuator-instrumentation package for a continuous process, non-critical flow loop controlled throughout the plant. Engineered from the ground up, the Valtek GS has achieved optimum performance at minimum total cost. It does this by pursuing the simple design philosophy of building an instrumented control valve package that is “everything it needs to be” by providing the breadth and depth of engineered control under the Valtek trusted name.

The Valtek GS is a fully integrated valve-actuator-instrumentation package for a continuous process, non-critical flow loop controlled throughout the plant. Engineered from the ground up, the Valtek GS has achieved optimum performance at minimum total cost. It does this by pursuing the simple design philosophy of building an instrumented control valve package that is “everything it needs to be” by providing the breadth and depth of engineered control under the Valtek trusted name. -

The HPFlow is designed for high pressure applications up to 60,000 psi for very special needs. With the unique split body design it is possible to clamp the seat in between the body parts to handle these extreme pressure ratings. In combination with high pressure there is very often the need to handle also high diferential pressure. In this case the HPFlow series offers an axial multi-stage trim design.

The HPFlow is designed for high pressure applications up to 60,000 psi for very special needs. With the unique split body design it is possible to clamp the seat in between the body parts to handle these extreme pressure ratings. In combination with high pressure there is very often the need to handle also high diferential pressure. In this case the HPFlow series offers an axial multi-stage trim design. -

Many years of experience in the manufacture of lined ball and plug valves and the sophisticated experience of manufacturing excellent reproducible trims for linear valves are combined in this new product. High quality lining materials such as PFA (standard), PVDF, PP, ETFE and FEP as well as PFA antistatic, cover most mediums and applications. The revolutionary PTFE bellows design allows a standard pressure rating of CL150. The increased flow capacity means that the most economical valve can be chosen for the application.

Many years of experience in the manufacture of lined ball and plug valves and the sophisticated experience of manufacturing excellent reproducible trims for linear valves are combined in this new product. High quality lining materials such as PFA (standard), PVDF, PP, ETFE and FEP as well as PFA antistatic, cover most mediums and applications. The revolutionary PTFE bellows design allows a standard pressure rating of CL150. The increased flow capacity means that the most economical valve can be chosen for the application. -

The Valtek Mark 100 control valve is designed to meet the needs of large applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 100 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes.

The Valtek Mark 100 control valve is designed to meet the needs of large applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 100 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes. -

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback -

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes.

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes. -

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform.

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform.