-

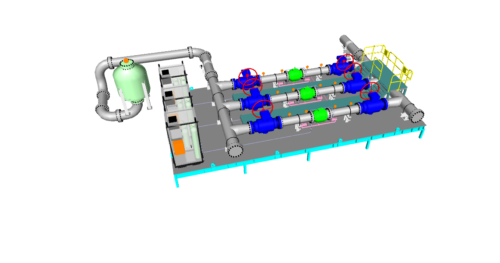

N2X complete surge relief skid system can provide a cost-effective modular solution in lieu of on-site construction. It includes N2X's industry leading NCS nitrogen control system housed in the POD nitrogen control cabinet, surge relief valves, isolation valves, plenums, piping, fitting and platform, all mounted on a skid. Based on the transient hydraulic analysis, the complete sytem is designed to ensure accurate, reliable, and repeatable control accuracy of your pipeline overpressure protection.

N2X complete surge relief skid system can provide a cost-effective modular solution in lieu of on-site construction. It includes N2X's industry leading NCS nitrogen control system housed in the POD nitrogen control cabinet, surge relief valves, isolation valves, plenums, piping, fitting and platform, all mounted on a skid. Based on the transient hydraulic analysis, the complete sytem is designed to ensure accurate, reliable, and repeatable control accuracy of your pipeline overpressure protection. -

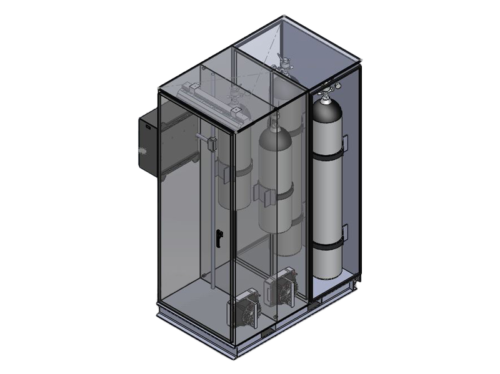

The POD series is engineered for ultimate temperature control and accessibility. It encloses the control system and required plenums in a cabinet large enough for site personnel to enter. The rear of the cabinet has a drop down ramp access to the high-pressure nitrogen cylinders for when replacements are required. Nitrogen adjustment can be made without opening the heated area.With our ability to fabricate and test in the USA and Canada, we can design to build the POD series control system to your required specifications. All engineering phases necessary will be exercised with this elite control system technology.

The POD series is engineered for ultimate temperature control and accessibility. It encloses the control system and required plenums in a cabinet large enough for site personnel to enter. The rear of the cabinet has a drop down ramp access to the high-pressure nitrogen cylinders for when replacements are required. Nitrogen adjustment can be made without opening the heated area.With our ability to fabricate and test in the USA and Canada, we can design to build the POD series control system to your required specifications. All engineering phases necessary will be exercised with this elite control system technology. -

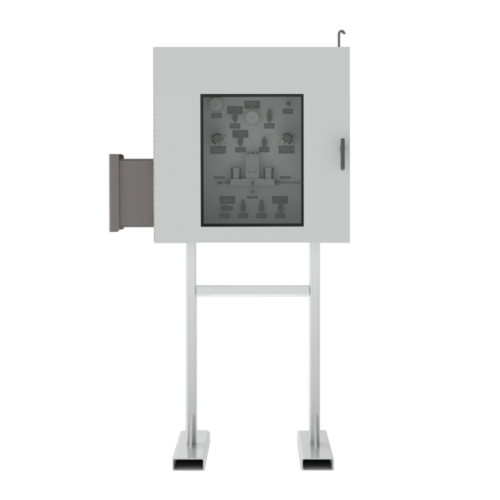

The HK control system provides NCS series functionality with the added protection of an enclosure as well as temperature compensation through internal heating and regulation. This series encloses the entire control system with only externals components being the plenums and nitrogen cylinders. Our stands provide the ability to affix plenums or nitrogen cylinders. Other customer requested options can be integrated into this control system.With the plenum bottles still likely being exposed to the elements, we would recommend investing in our Temperature Control Accessories to minimize pressure compensation within the system.

The HK control system provides NCS series functionality with the added protection of an enclosure as well as temperature compensation through internal heating and regulation. This series encloses the entire control system with only externals components being the plenums and nitrogen cylinders. Our stands provide the ability to affix plenums or nitrogen cylinders. Other customer requested options can be integrated into this control system.With the plenum bottles still likely being exposed to the elements, we would recommend investing in our Temperature Control Accessories to minimize pressure compensation within the system. -

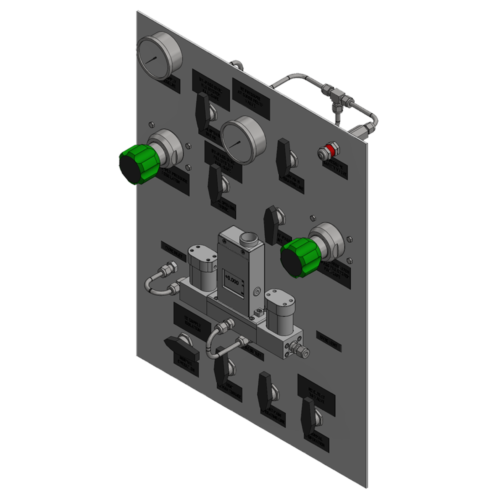

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems.

N2X's unique Dual Valve Regulating Control system (DVRC) can control the nitrogen set point with a market leading accuracy of +/- 0.25 psi control. Using patented control algorithms while implementing a complete understanding of the application, N2X can assure you that required relief set points are accurately and reliably maintained.Not only does this technology assure that no unexpected events result in environmental release and/or OHS incidents, it reduces costly and frequent field visits due to system alarms. Our systems also increase the life of typical nitrogen consumption by not exhausting as much nitrogen as non-proportionally controlled systems. -

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow.

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow. -

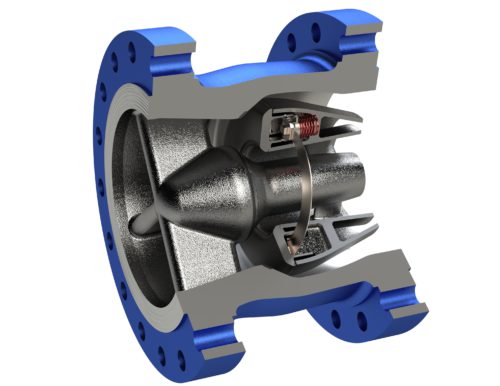

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

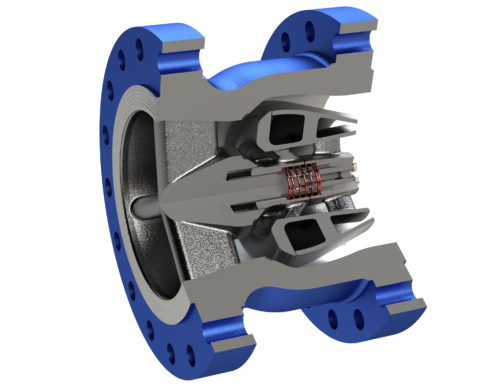

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

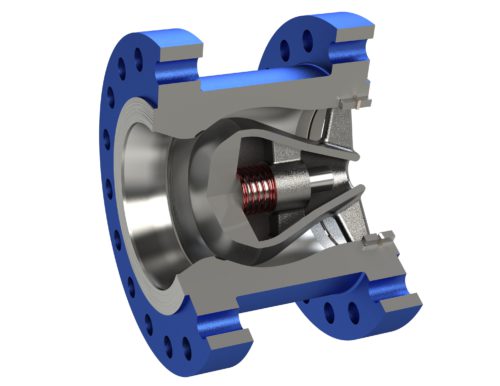

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND)

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND) -

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. -

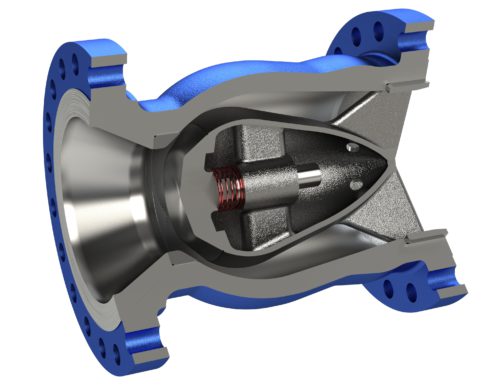

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. -

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together.

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. -

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD)

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD) -

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback