-

Cashco’s Model 3200 in-line conservation breather vent is part of the Valve Concepts, Inc. modular vent product line. The Model 3200 can easily be field converted to a vacuum-only vent, a pressure/vacuum vent to the atmosphere, and can either be direct acting or pilot operated. Only Valve Concepts offers complete modularity throughout its complete vent product line.

Cashco’s Model 3200 in-line conservation breather vent is part of the Valve Concepts, Inc. modular vent product line. The Model 3200 can easily be field converted to a vacuum-only vent, a pressure/vacuum vent to the atmosphere, and can either be direct acting or pilot operated. Only Valve Concepts offers complete modularity throughout its complete vent product line. -

The Model 3300 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3300 can easily be field converted to an end-of-line pressure/vacuum relief vent with the addition of weather hood components or an in-line pressure/vacuum relief with the addition of pipe away body components.

The Model 3300 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3300 can easily be field converted to an end-of-line pressure/vacuum relief vent with the addition of weather hood components or an in-line pressure/vacuum relief with the addition of pipe away body components. -

The Model 3600 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3600 can easily be field converted to a pressure-only vent, a pressure/vacuum vent with pipe away, and can either be direct acting or pilot operated. Only Valve Concepts offers complete modularity throughout its complete vent product line.

The Model 3600 end-of-line conservation breather vent is part of Valve Concepts, Inc. modular vent product line. The Model 3600 can easily be field converted to a pressure-only vent, a pressure/vacuum vent with pipe away, and can either be direct acting or pilot operated. Only Valve Concepts offers complete modularity throughout its complete vent product line. -

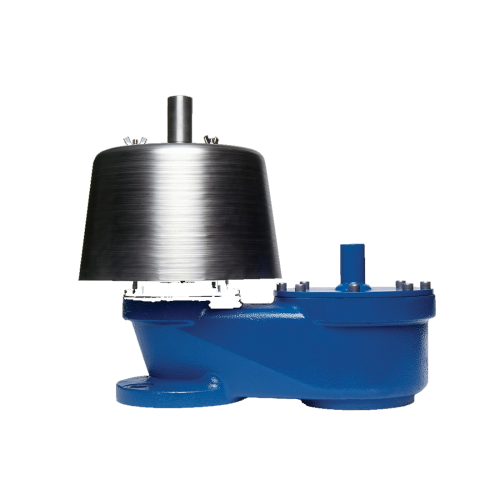

The Model 3K00 Pressure / Vacuum Vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.

The Model 3K00 Pressure / Vacuum Vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank. -

The Model 4200 pipe-away conservation vent is part of the Valve Concepts, Inc. modular vent product line. The Model 4200 can easily be converted to a vacuum-only vent or end-of-line pressure/vacuum vent and can either be direct-acting or pilot-operated. Only Valve Concepts, Inc. offers complete modularity throughout its complete vent product line.

The Model 4200 pipe-away conservation vent is part of the Valve Concepts, Inc. modular vent product line. The Model 4200 can easily be converted to a vacuum-only vent or end-of-line pressure/vacuum vent and can either be direct-acting or pilot-operated. Only Valve Concepts, Inc. offers complete modularity throughout its complete vent product line. -

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.

The Model 3100 end-of-line conservation breather vent is designed for use on atmospheric and low-pressure storage tanks where pressure and vacuum relief are required. Weight-loaded pallets in the vent housing allow the intake of air and the escape of vapors as the tank breathes due to thermal changes and product movement in and out of the tank. The pallets open and close to permit in-breathing and out-breathing necessary to maintain the tank pressure within permissible limits to avoid damage to the tank.