-

Ceresist ceramic lined pipe spools are designed to outlast linings such as glass, rubber, basalt, hard facings, coatings, trowelable linings, cure-in-place linings, and plastics that are commonly used to extend the life of piping systems. These materials are only a fraction of the hardness and wear resistance of our ceramics, and in the presence of corrosion or high temperatures, most linings become severely incompatible and their use is extremely limited

Ceresist ceramic lined pipe spools are designed to outlast linings such as glass, rubber, basalt, hard facings, coatings, trowelable linings, cure-in-place linings, and plastics that are commonly used to extend the life of piping systems. These materials are only a fraction of the hardness and wear resistance of our ceramics, and in the presence of corrosion or high temperatures, most linings become severely incompatible and their use is extremely limited -

Ceresist's CER-1200 fine-grain alumina ceramic is next to diamond in hardness and outlasts steel by 12 times and Ni-hard by 5 times. Ceresist wear-resistant products are a long-term, maintenance-free solution in systems that experience rapid degradation due to sliding abrasion, erosion, and impact - even in highly corrosive or high-temperature services.

Ceresist's CER-1200 fine-grain alumina ceramic is next to diamond in hardness and outlasts steel by 12 times and Ni-hard by 5 times. Ceresist wear-resistant products are a long-term, maintenance-free solution in systems that experience rapid degradation due to sliding abrasion, erosion, and impact - even in highly corrosive or high-temperature services. -

The Cashco Model D is a pressure-reducing regulator that is proven to be widely used in different applications including gases, liquids, cryogenics, and steam. One of the main features of the Model D is that it can handle mid-range pressure drops while maintaining good stability. This regulator handles inlet pressures up to 600 psig and outlet pressures up to 250 psig in multiple spring ranges.

The Cashco Model D is a pressure-reducing regulator that is proven to be widely used in different applications including gases, liquids, cryogenics, and steam. One of the main features of the Model D is that it can handle mid-range pressure drops while maintaining good stability. This regulator handles inlet pressures up to 600 psig and outlet pressures up to 250 psig in multiple spring ranges. -

The Cashco Model DA1 is a high-performance, spring-operated, flow-to-open, pressure-reducing regulator with internal pressure balancing piston-cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous or liquid services. It can handle an inlet pressure of up to 1480 psi and an outlet pressure of 450 psi in multiple spring ranges.

The Cashco Model DA1 is a high-performance, spring-operated, flow-to-open, pressure-reducing regulator with internal pressure balancing piston-cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous or liquid services. It can handle an inlet pressure of up to 1480 psi and an outlet pressure of 450 psi in multiple spring ranges. -

The Cashco Model DA4 is a high-performance, pressure-loaded diaphragm-type, flow-to-open pressure-reducing regulator. It can handle an inlet pressure of up to 3705 psi and up to 1500 psig pressure drop in multiple spring ranges. The model DA4 can be utilized in a wide variety of applications such as clean fluids, natural gas, air, oil, and corrosive and non-corrosive chemical services. With the pressure-loaded diaphragm and the balanced trim design, the DA4 can meet or exceeds that of the competitive pressure-loaded or pilot-operated designs by providing high flow capacity and high-pressure drop capability.

The Cashco Model DA4 is a high-performance, pressure-loaded diaphragm-type, flow-to-open pressure-reducing regulator. It can handle an inlet pressure of up to 3705 psi and up to 1500 psig pressure drop in multiple spring ranges. The model DA4 can be utilized in a wide variety of applications such as clean fluids, natural gas, air, oil, and corrosive and non-corrosive chemical services. With the pressure-loaded diaphragm and the balanced trim design, the DA4 can meet or exceeds that of the competitive pressure-loaded or pilot-operated designs by providing high flow capacity and high-pressure drop capability. -

Cashco’s Model DA5 is a high-capacity self-contained, spring-operated, back-pressure regulator with a top-guided piston cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous services. It can handle both an inlet pressure and pressure drop up to 675 psi.

Cashco’s Model DA5 is a high-capacity self-contained, spring-operated, back-pressure regulator with a top-guided piston cylinder that provides high flow capacity and high-pressure drop capability. It can be utilized in different applications, but its proven specialty appeared in clean gaseous services. It can handle both an inlet pressure and pressure drop up to 675 psi. -

The DFS series scotch and Yoke Pneumatic Actuators are heavy-duty actuators for operating large diameter ball valves, butterfly valves, plug valves and other 90˚ rotating mechanism. Available with two yoke deigns namely symmetrical design and canted yoke design. Cylinder blocks are plated with hard chromium to increase the service life of the actuators. The piston rod and guide block connection superior surface finish and the self-lubricating bearings maximize the input energy transfer directly to the valve stem and ensure reliable operation over the service life of the actuator. Can be supplied with the complete line of controls and monitoring accessories, including hand wheel, hydraulic manual override, limit switches, solenoid valves, positioners and other control accessories.

The DFS series scotch and Yoke Pneumatic Actuators are heavy-duty actuators for operating large diameter ball valves, butterfly valves, plug valves and other 90˚ rotating mechanism. Available with two yoke deigns namely symmetrical design and canted yoke design. Cylinder blocks are plated with hard chromium to increase the service life of the actuators. The piston rod and guide block connection superior surface finish and the self-lubricating bearings maximize the input energy transfer directly to the valve stem and ensure reliable operation over the service life of the actuator. Can be supplied with the complete line of controls and monitoring accessories, including hand wheel, hydraulic manual override, limit switches, solenoid valves, positioners and other control accessories. -

The Vahn-Tech Series DFS is an economic rack and pinion style pnuematic actuator, with both captured coil spring-return and double-acting configurations. With standardized accessory (VDI/VDE 3845) and valve (ISO 5211) mounting pads, packaging with Vahn-Tech and third-party valves and accessories is simplified and easy.

The Vahn-Tech Series DFS is an economic rack and pinion style pnuematic actuator, with both captured coil spring-return and double-acting configurations. With standardized accessory (VDI/VDE 3845) and valve (ISO 5211) mounting pads, packaging with Vahn-Tech and third-party valves and accessories is simplified and easy. -

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services.

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services. -

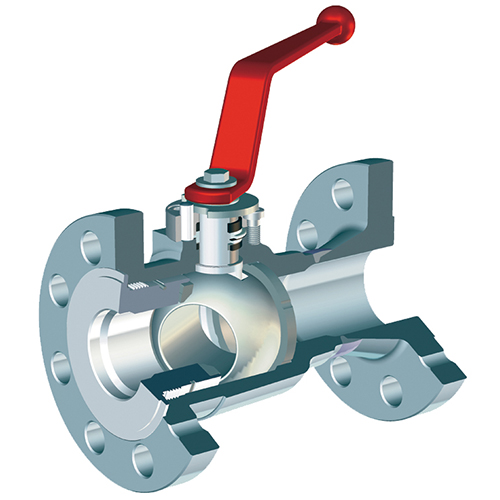

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators.

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators. -

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve.

The DrainFlow Series 051000 valve is typically used for on-off bottom drain tank applications, where flushing or fluid transfer is necessary. The valve mounts flush to the tank with a plug extending into the tank and with the seat ring flush with the inner wall of the tank. The valve’s compact, lightweight design is ideal for in-line maintenance under the tank. It can be specified with either a 45° or 60° outlet angle. Other options include bellows seal, normalising fins, a special pocketfree body, steam jacketing or a plug that retracts into the body (as opposed to the standard design with an extending plug). The tank flush valve can also be supplied as a control valve. -

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance.

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance. -

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance.

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance. -

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications.

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications. -

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications.

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications. -

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated.

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated. -

The NAF Duball DL Pocket Valve is the pulp and paper industry's choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated.

The NAF Duball DL Pocket Valve is the pulp and paper industry's choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated. -

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements.

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements. -

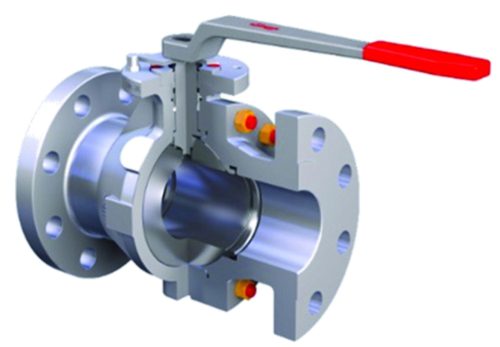

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads. -

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements.

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements.