-

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607.

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607. -

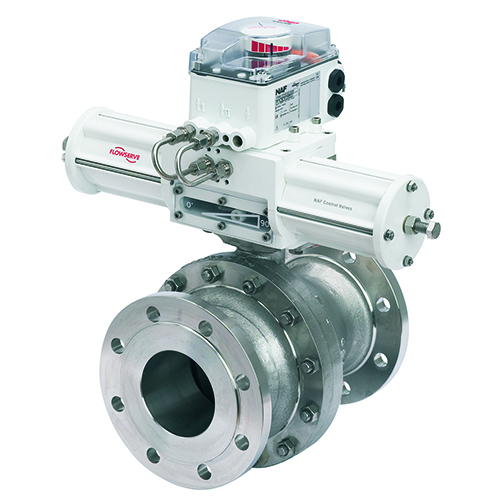

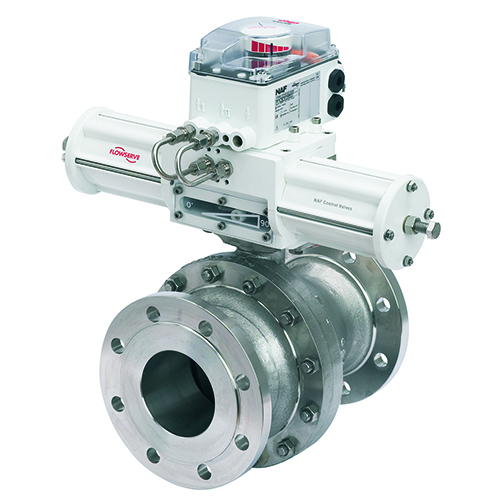

The NAF Trunnball DL is a full-bore trunnion-mounted ball valve, developed by Flowserve engineers with more than 80 years of experience manufacturing ball valves. The ball is supported by two large, low friction trunnion bearings for consistent low torque even at high differential pressures. Due to its bi-directional tightness, low friction and high controllability, it is an excellent choice for isolation, on/off and modulating control applications.

The NAF Trunnball DL is a full-bore trunnion-mounted ball valve, developed by Flowserve engineers with more than 80 years of experience manufacturing ball valves. The ball is supported by two large, low friction trunnion bearings for consistent low torque even at high differential pressures. Due to its bi-directional tightness, low friction and high controllability, it is an excellent choice for isolation, on/off and modulating control applications. -

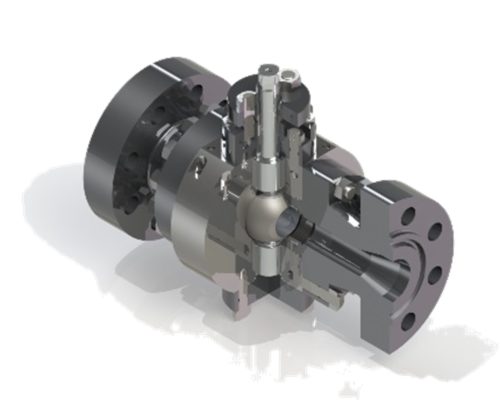

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators.

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators. -

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief.

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief. -

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory.

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory. -

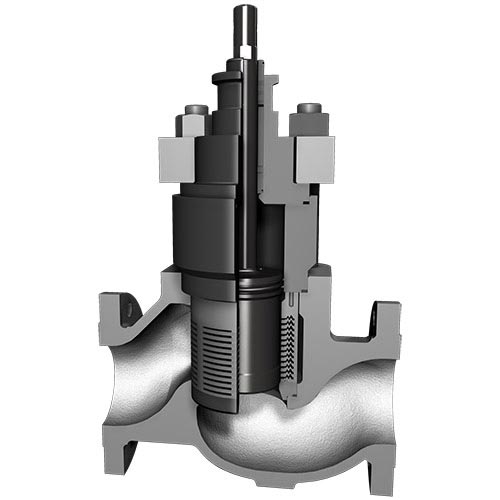

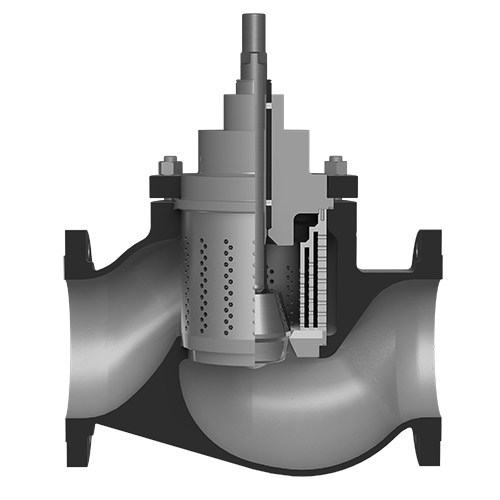

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids.

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids. -

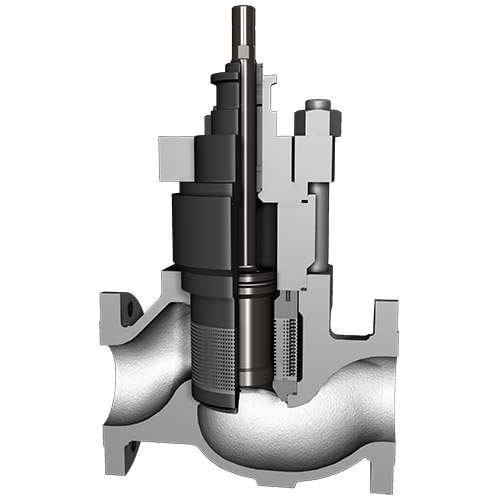

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services.

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services. -

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise.

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise. -

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise.

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise. -

The NAF Torex, High-Performance butterfly valve is available with either metal-to-metal or soft seats. Due to its unique design and triple offset, it closes extremely tight. It can be used both as a control valve and as a shut-off valve.This valve can be supplied in either wafer or lugged versions. The valves are also available in other materials e.g. Carbon steel, and Titanium, other stainless steel materials and in Fire-safe design.

The NAF Torex, High-Performance butterfly valve is available with either metal-to-metal or soft seats. Due to its unique design and triple offset, it closes extremely tight. It can be used both as a control valve and as a shut-off valve.This valve can be supplied in either wafer or lugged versions. The valves are also available in other materials e.g. Carbon steel, and Titanium, other stainless steel materials and in Fire-safe design. -

The Valdisk TX3 is a high performance triple offset butterfly control valve capable of closing with zero leakage. The precision seat and seal are machined at an offset angle creating even seat loading around the entire seat ring and eliminating rubbing between the seat and seal during opening and throttling. This design provides repeatable long-lasting zero leakage shut-off.

The Valdisk TX3 is a high performance triple offset butterfly control valve capable of closing with zero leakage. The precision seat and seal are machined at an offset angle creating even seat loading around the entire seat ring and eliminating rubbing between the seat and seal during opening and throttling. This design provides repeatable long-lasting zero leakage shut-off. -

The Valtek Valdisk valve is a high-performance butterfly control valve. Its double-offset shaft provides eccentric-cammed disc rotation to lift it out of the seat, thus immediately eliminating seat friction, to improve throttling control and reduce seat wear. A one-piece splined shaft connected to a clamped actuator lever provides excellent throttling control. Its soft seating arrangement is designed for bubble-tight shutoff while maintaining low breakout torque.

The Valtek Valdisk valve is a high-performance butterfly control valve. Its double-offset shaft provides eccentric-cammed disc rotation to lift it out of the seat, thus immediately eliminating seat friction, to improve throttling control and reduce seat wear. A one-piece splined shaft connected to a clamped actuator lever provides excellent throttling control. Its soft seating arrangement is designed for bubble-tight shutoff while maintaining low breakout torque. -

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety.

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety. -

The NAF Trunnball DL is a full-bore trunnion-mounted ball valve, developed by Flowserve engineers with more than 80 years of experience manufacturing ball valves. The ball is supported by two large, low friction trunnion bearings for consistent low torque even at high differential pressures. Due to its bi-directional tightness, low friction and high controllability, it is an excellent choice for isolation, on/off and modulating control applications.

The NAF Trunnball DL is a full-bore trunnion-mounted ball valve, developed by Flowserve engineers with more than 80 years of experience manufacturing ball valves. The ball is supported by two large, low friction trunnion bearings for consistent low torque even at high differential pressures. Due to its bi-directional tightness, low friction and high controllability, it is an excellent choice for isolation, on/off and modulating control applications. -

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications.

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications. -

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated.

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated.