-

The Valtek GS is a fully integrated valve-actuator-instrumentation package for a continuous process, non-critical flow loop controlled throughout the plant. Engineered from the ground up, the Valtek GS has achieved optimum performance at minimum total cost. It does this by pursuing the simple design philosophy of building an instrumented control valve package that is “everything it needs to be” by providing the breadth and depth of engineered control under the Valtek trusted name.

The Valtek GS is a fully integrated valve-actuator-instrumentation package for a continuous process, non-critical flow loop controlled throughout the plant. Engineered from the ground up, the Valtek GS has achieved optimum performance at minimum total cost. It does this by pursuing the simple design philosophy of building an instrumented control valve package that is “everything it needs to be” by providing the breadth and depth of engineered control under the Valtek trusted name. -

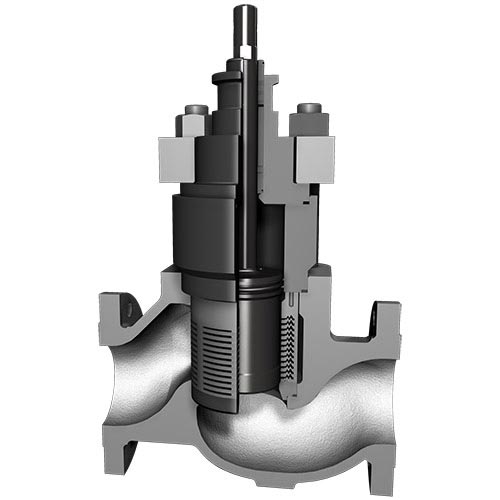

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions.

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions. -

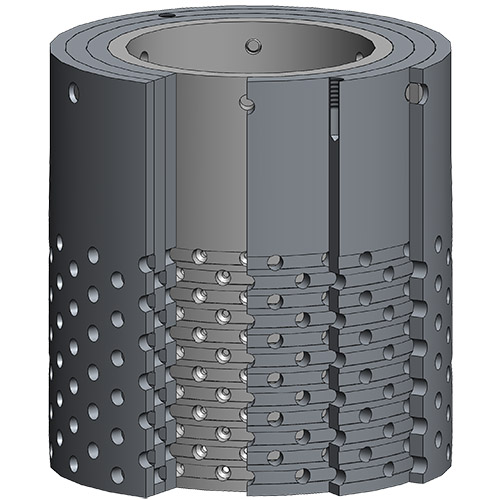

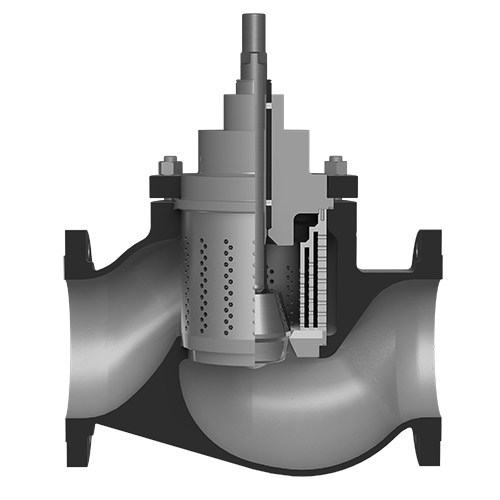

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results.

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results. -

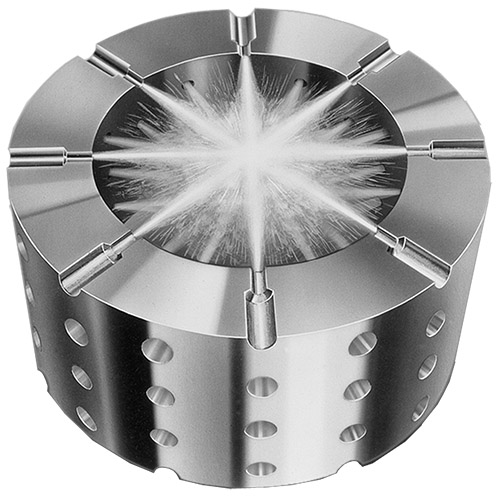

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services.

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services. -

The Valtek VR rotary cylinder actuator is a high pressure, compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The standard splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 150 psi (10.3 Bar) to eliminate the need for a pressure regulator. The high stiffness provides firm control from 0 to 90 degrees.

The Valtek VR rotary cylinder actuator is a high pressure, compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The standard splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 150 psi (10.3 Bar) to eliminate the need for a pressure regulator. The high stiffness provides firm control from 0 to 90 degrees. -

The Valtek NR diaphragm actuator is a compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 80 psi (6 Bar). The high stiffness and rolling diaphragm provides firm control from 0 to 90 degrees.

The Valtek NR diaphragm actuator is a compact actuator with high torque and pneumatic stiffness for excellent throttling capabilities. The splined shaft connection eliminates backlash for precise control. Designed for supply air pressures to 80 psi (6 Bar). The high stiffness and rolling diaphragm provides firm control from 0 to 90 degrees. -

Valtek VL series spring cylinder linear actuators are powerful, compact, high-performance pneumatic actuators that provide solid throttling or on-off operation for automatic control valves. The positioner supplies air to both sides of the piston, providing stiff, precise movement and high-frequency response and quick stroke speeds.

Valtek VL series spring cylinder linear actuators are powerful, compact, high-performance pneumatic actuators that provide solid throttling or on-off operation for automatic control valves. The positioner supplies air to both sides of the piston, providing stiff, precise movement and high-frequency response and quick stroke speeds. -

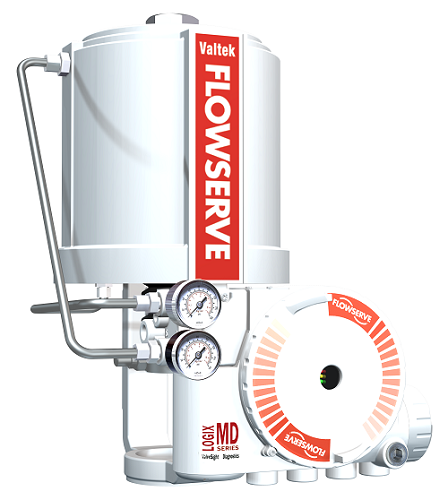

The StarPac 3 intelligent control system offers repeatability, accuracy and quick system response time with a small footprint and simple installation. It can stand alone or be integrated into a system, and is available for a variety of applications including oil and gas, chemical, paper, mining, industrial gases and power generation. Unique to the market, StarPac intelligent control systems give users an integrated view of the process at a single point and can improve plant operation at a lower installed cost than conventional control systems. The StarPac 3 builds on previous designs. Upgraded features include explosion-proof housing, USB and infrared interface, updated electronics, stainless steel options and enhanced positioner functions.

The StarPac 3 intelligent control system offers repeatability, accuracy and quick system response time with a small footprint and simple installation. It can stand alone or be integrated into a system, and is available for a variety of applications including oil and gas, chemical, paper, mining, industrial gases and power generation. Unique to the market, StarPac intelligent control systems give users an integrated view of the process at a single point and can improve plant operation at a lower installed cost than conventional control systems. The StarPac 3 builds on previous designs. Upgraded features include explosion-proof housing, USB and infrared interface, updated electronics, stainless steel options and enhanced positioner functions. -

The Valtek NT 3000 Series Electro-Pneumatic Transducer is an active I/P Transducer that is used with a milliamp electricl control signal. It is interchangeable with the XL Series or Beta Series Pneumatic Positioners and can be mounted on either Valtek Linear or Valtek Rotary Actuators without modification.

The Valtek NT 3000 Series Electro-Pneumatic Transducer is an active I/P Transducer that is used with a milliamp electricl control signal. It is interchangeable with the XL Series or Beta Series Pneumatic Positioners and can be mounted on either Valtek Linear or Valtek Rotary Actuators without modification. -

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments.

The Beta positioner is a single or double-acting, force balanced instrument that provides fast, sensitive and accurate positioning of diaphragm or cylinder actuators. It is available with either a pneumatic module for air control signals or an electro-pneumatic (I/P) module for milliamp current control signals. Designed for high performance, this positioner is compact, field reversible and ruggedly built for reliability in severe industrial environments. -

The Valtek XL Series (XL and XL90), two-stage positioners offer fast and sensitive dynamic response characteristics to meet extremely demanding control objectives. The positioners are available with either an electro-pneumatic (I/P) transducer module for milliamp current control signals or a pneumatic module for aircontrol signals. Designed for high performance, these positioners are field reversible and ruggedly built for reliability in severe industrial environments.

The Valtek XL Series (XL and XL90), two-stage positioners offer fast and sensitive dynamic response characteristics to meet extremely demanding control objectives. The positioners are available with either an electro-pneumatic (I/P) transducer module for milliamp current control signals or a pneumatic module for aircontrol signals. Designed for high performance, these positioners are field reversible and ruggedly built for reliability in severe industrial environments. -

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow.

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow. -

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids.

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids. -

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services.

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services. -

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise.

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise.