-

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform.

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform. -

Built from the same basis of design principles as the Mark One but fabricated from bar stock, the Mark Two is an extremely versatile control valve. Due to its constructions, it is available in many different configurations with shorter lead times than conventionally cast valve bodies, even in high-pressure classes or special alloys.

Built from the same basis of design principles as the Mark One but fabricated from bar stock, the Mark Two is an extremely versatile control valve. Due to its constructions, it is available in many different configurations with shorter lead times than conventionally cast valve bodies, even in high-pressure classes or special alloys. -

The Valtek Mark 100 control valve is designed to meet the needs of large applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 100 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes.

The Valtek Mark 100 control valve is designed to meet the needs of large applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 100 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes. -

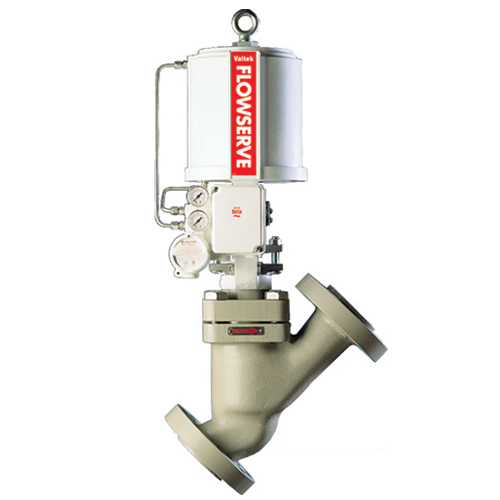

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback

The Valtek® Compressor Anti-Surge Valve from Flowserve represents a revolutionary solution to anti-surge control by combining precise control and exceptional responsiveness in a simple, reliable package. It protects compressors from catastrophic surge damage by providing exceptional response for driving the valve open when needed and in a steady-state position when in recycle. Key components: • Mark 100SC™ angle body valve • Logix 3800JF™ positioner • MegaStream™ noise control • Stealth™ noise control • Linear piston actuators • Actuator cushions • SpiralTrack™ feedback -

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes.

The Mark 200 is one of the most dynamic Flowserve control valve offerings designed to meet the needs of high-pressure large capacity applications. It offers the highest flow capacity, as well as fast, easy maintenance in both gas and liquid control. The Mark 200 also has longer stroke lengths, providing finer control and resulting in superior process control in smaller valve sizes. -

The Valtek FlowTop GS control valve (types V746 and V748) improves the reliability and uptime of production processes while minimizing operating and maintenance costs. Designed for general service applications, the FlowTop GS globe valve is a competitively priced, fully integrated valve-actuator-instrumentation package for continuous process flow loop control throughout the plant.

The Valtek FlowTop GS control valve (types V746 and V748) improves the reliability and uptime of production processes while minimizing operating and maintenance costs. Designed for general service applications, the FlowTop GS globe valve is a competitively priced, fully integrated valve-actuator-instrumentation package for continuous process flow loop control throughout the plant. -

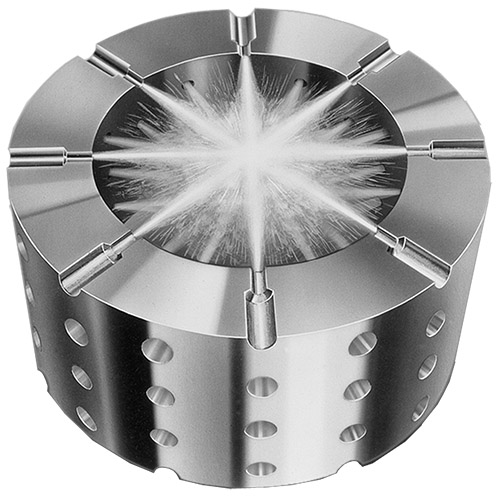

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services.

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services. -

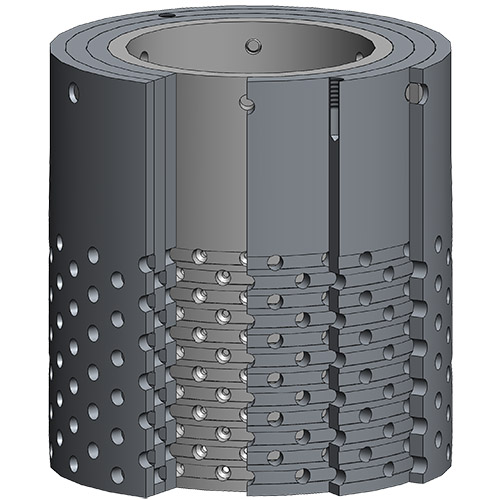

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results.

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results. -

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions.

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions. -

The Valtek ShearStream is a segmented, ball control valve that provides exceptional control and rangeability for the process industries. Designed to overcome the problems of harsh, particle entrained processes, ShearStream also provides accurate, reliable control in a broad range of applications, such as chemical, power and petroleum.

The Valtek ShearStream is a segmented, ball control valve that provides exceptional control and rangeability for the process industries. Designed to overcome the problems of harsh, particle entrained processes, ShearStream also provides accurate, reliable control in a broad range of applications, such as chemical, power and petroleum. -

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety.

The MaxFlo 4 is a high-performance eccentric rotary plug control valve. The flow path is unobstructed by the shaft, allowing higher capacity for a given valve size. This noncrossover shaft design also eliminates shaft damage from erosive process fluids. The shaft is designed per ASME B16.34 Section 6.5 to prevent the stem from being removed while the valve is under pressure for increased safety. -

The Valtek Valdisk valve is a high-performance butterfly control valve. Its double-offset shaft provides eccentric-cammed disc rotation to lift it out of the seat, thus immediately eliminating seat friction, to improve throttling control and reduce seat wear. A one-piece splined shaft connected to a clamped actuator lever provides excellent throttling control. Its soft seating arrangement is designed for bubble-tight shutoff while maintaining low breakout torque.

The Valtek Valdisk valve is a high-performance butterfly control valve. Its double-offset shaft provides eccentric-cammed disc rotation to lift it out of the seat, thus immediately eliminating seat friction, to improve throttling control and reduce seat wear. A one-piece splined shaft connected to a clamped actuator lever provides excellent throttling control. Its soft seating arrangement is designed for bubble-tight shutoff while maintaining low breakout torque. -

The Valdisk TX3 is a high performance triple offset butterfly control valve capable of closing with zero leakage. The precision seat and seal are machined at an offset angle creating even seat loading around the entire seat ring and eliminating rubbing between the seat and seal during opening and throttling. This design provides repeatable long-lasting zero leakage shut-off.

The Valdisk TX3 is a high performance triple offset butterfly control valve capable of closing with zero leakage. The precision seat and seal are machined at an offset angle creating even seat loading around the entire seat ring and eliminating rubbing between the seat and seal during opening and throttling. This design provides repeatable long-lasting zero leakage shut-off.