-

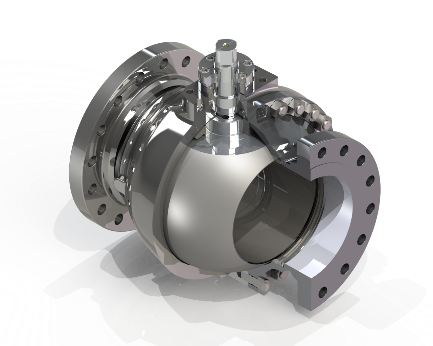

Argus FK76M trunnion mounted ball valves are engineered to deliver long-lasting, tight shut-off performance in oil and gas, petrochemical and chemical industry applications. It features a modular design that allows simplified adaptation to diverse safety, emissions and performance requirements. The FK76M ball valve is available in standard and severe service designs and offers metal-seated and soft-seated configurations for reliable sealing performance. Special and customized designs are also available for ultimate high cycle, high temperature and similar challenging applications. These valves are designed to meet API 6D and ASME B16.34 requirements (API 608 on request). Fugitive emission to ISO 15848 (API 641 on request). Fire-safe to API 607 or ISO 10497.

Argus FK76M trunnion mounted ball valves are engineered to deliver long-lasting, tight shut-off performance in oil and gas, petrochemical and chemical industry applications. It features a modular design that allows simplified adaptation to diverse safety, emissions and performance requirements. The FK76M ball valve is available in standard and severe service designs and offers metal-seated and soft-seated configurations for reliable sealing performance. Special and customized designs are also available for ultimate high cycle, high temperature and similar challenging applications. These valves are designed to meet API 6D and ASME B16.34 requirements (API 608 on request). Fugitive emission to ISO 15848 (API 641 on request). Fire-safe to API 607 or ISO 10497. -

The FK76C split-body, full-bore, trunnion-mounted ball valve represents the highest standards in valve technology. Its superfine finished, trunnion-mounted ball design is just one of its many important design features. Among them are an anti-blow out stem,long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The FK76C split-body, full-bore, trunnion-mounted ball valve represents the highest standards in valve technology. Its superfine finished, trunnion-mounted ball design is just one of its many important design features. Among them are an anti-blow out stem,long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads. -

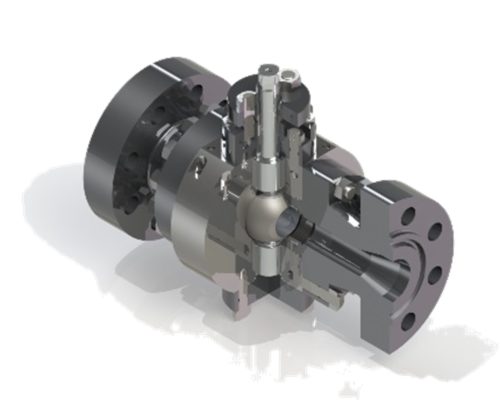

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory.

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory. -

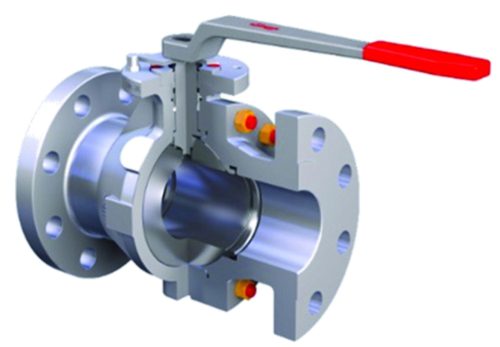

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607.

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607. -

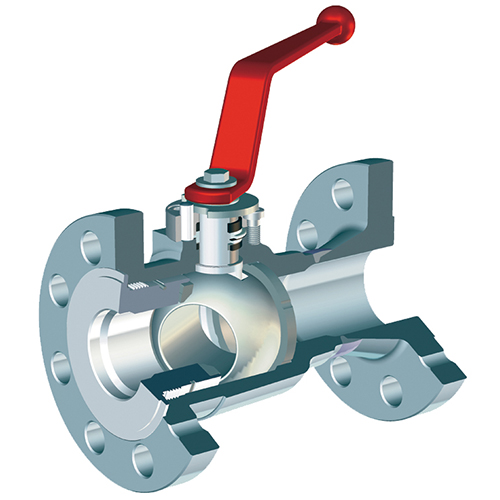

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements.

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements. -

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements.

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements. -

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.