-

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction.

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction. -

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief.

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief. -

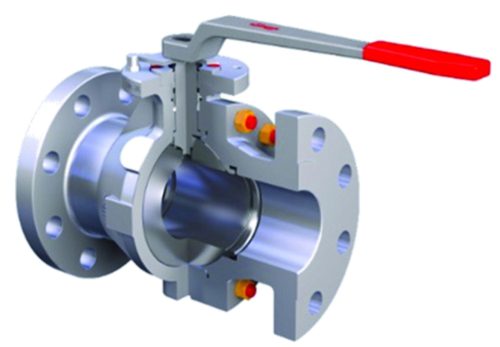

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators.

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators. -

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance.

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance. -

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance.

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance. -

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications.

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications. -

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated.

The NAF Duball DL Pocket Valve is the pulp and paper industry’s choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated. -

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements.

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements. -

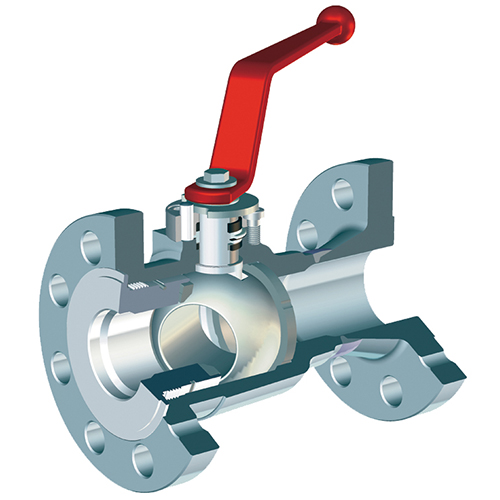

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads. -

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements.

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements. -

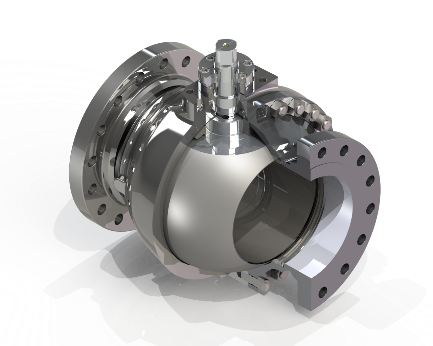

The FK76C split-body, full-bore, trunnion-mounted ball valve represents the highest standards in valve technology. Its superfine finished, trunnion-mounted ball design is just one of its many important design features. Among them are an anti-blow out stem,long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The FK76C split-body, full-bore, trunnion-mounted ball valve represents the highest standards in valve technology. Its superfine finished, trunnion-mounted ball design is just one of its many important design features. Among them are an anti-blow out stem,long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads. -

Argus FK76M trunnion mounted ball valves are engineered to deliver long-lasting, tight shut-off performance in oil and gas, petrochemical and chemical industry applications. It features a modular design that allows simplified adaptation to diverse safety, emissions and performance requirements. The FK76M ball valve is available in standard and severe service designs and offers metal-seated and soft-seated configurations for reliable sealing performance. Special and customized designs are also available for ultimate high cycle, high temperature and similar challenging applications. These valves are designed to meet API 6D and ASME B16.34 requirements (API 608 on request). Fugitive emission to ISO 15848 (API 641 on request). Fire-safe to API 607 or ISO 10497.

Argus FK76M trunnion mounted ball valves are engineered to deliver long-lasting, tight shut-off performance in oil and gas, petrochemical and chemical industry applications. It features a modular design that allows simplified adaptation to diverse safety, emissions and performance requirements. The FK76M ball valve is available in standard and severe service designs and offers metal-seated and soft-seated configurations for reliable sealing performance. Special and customized designs are also available for ultimate high cycle, high temperature and similar challenging applications. These valves are designed to meet API 6D and ASME B16.34 requirements (API 608 on request). Fugitive emission to ISO 15848 (API 641 on request). Fire-safe to API 607 or ISO 10497. -

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607.

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607. -

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory.

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory. -

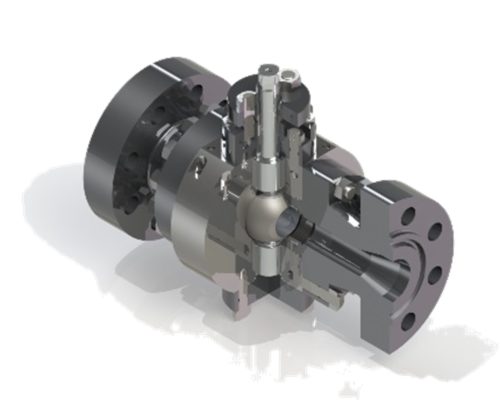

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience.

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience. -

Vahn-Tech DB Series funnel knife gate valve is used in service as a pneumatic residue discharge valve in pulp making, paper making and sewage treatment. This type of valve is well suited for high consistency media containing solids, fiber or residue, serving as a residue discharge valve on stock cleaners, gravity separators or pressurized screens. The "funnel" at the bottom of the collects waste discharged from the valve body during the closing stroke. This greatly reduces the wear between the body and gate, and prolongs the life cycle of the valve.

Vahn-Tech DB Series funnel knife gate valve is used in service as a pneumatic residue discharge valve in pulp making, paper making and sewage treatment. This type of valve is well suited for high consistency media containing solids, fiber or residue, serving as a residue discharge valve on stock cleaners, gravity separators or pressurized screens. The "funnel" at the bottom of the collects waste discharged from the valve body during the closing stroke. This greatly reduces the wear between the body and gate, and prolongs the life cycle of the valve. -

Vahn-Tech DC Series knife gate valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with handwheel, or can be automated with pneumatic cylinder or electric actuator for remote operation. The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles. The knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing.

Vahn-Tech DC Series knife gate valves are linear shut off valves that are light weight with compact construction. Valves are available as manual with handwheel, or can be automated with pneumatic cylinder or electric actuator for remote operation. The arc shape of the gate of our knife gate valve is designed to be particularly suitable for cutting off fluid containing fiber or suspended particles. The knife gate valves are ideal for many applications in the process industries of Pulp & Paper, Wastewater Treatment, Mining, Sugar Making and Chemical Processing. -

Vahn-Tech DF Series square knife gate valve is mainly used as pneumatic on/off valve for process control in pulp making slurry or sewage treatment. It is particularly suitable to serve as a residue discharger on equipment such as stock cleaners, gravity separators and hydra pulper in the paper making industry.

Vahn-Tech DF Series square knife gate valve is mainly used as pneumatic on/off valve for process control in pulp making slurry or sewage treatment. It is particularly suitable to serve as a residue discharger on equipment such as stock cleaners, gravity separators and hydra pulper in the paper making industry. -

Vahn-Tech DK Series knife gate valves are soft sealing shut off valves that are light weight with compact construction, and convenient to install and use. Valves are in full port design and with small flow resistance. When the gate is open, direct current flows between valve and pipeline. Valves can be operated manually with handwheel, or with automatic actuator for remote operation. The cone-shape design of the gates provides strong cutting force. The die-casting rubber seats are with bi-directional sealing. The main advantage of the valves is that when fully open, the medium will not flow into the valve chest, which prevents the pulp from settling in the valve chest and thus reducing the maintenance cost.

Vahn-Tech DK Series knife gate valves are soft sealing shut off valves that are light weight with compact construction, and convenient to install and use. Valves are in full port design and with small flow resistance. When the gate is open, direct current flows between valve and pipeline. Valves can be operated manually with handwheel, or with automatic actuator for remote operation. The cone-shape design of the gates provides strong cutting force. The die-casting rubber seats are with bi-directional sealing. The main advantage of the valves is that when fully open, the medium will not flow into the valve chest, which prevents the pulp from settling in the valve chest and thus reducing the maintenance cost.