-

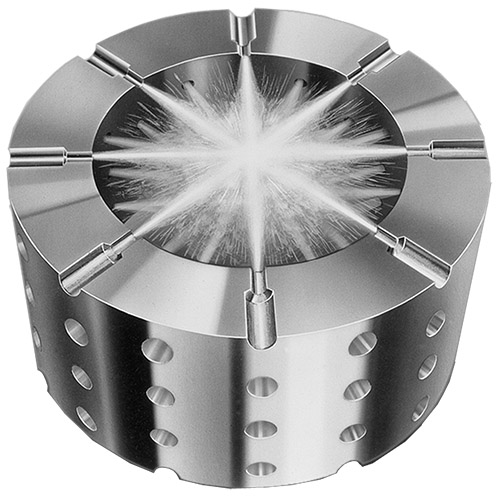

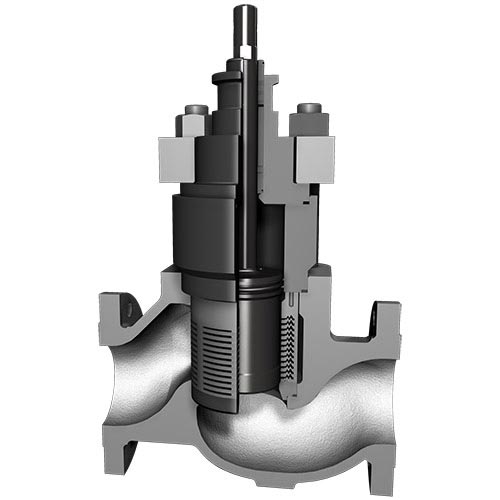

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services.

DiamondBack trim prevents cavitation from forming and minimizes hydrodynamic noise even in the most challenging liquid applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, never allowing cavitation to form. DiamondBack combines new advances in pressure drop management with previously proven technologies to create the most effective device capable of eliminating cavitation in the most demanding services. -

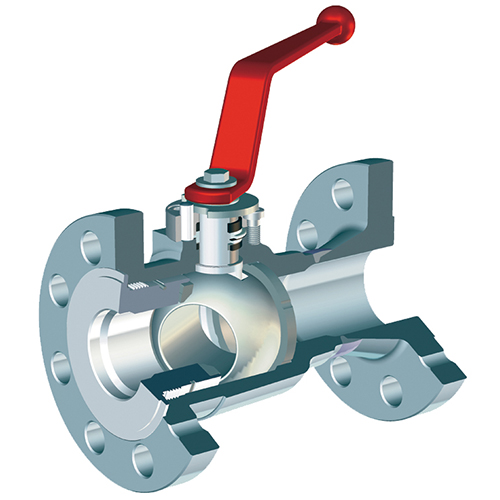

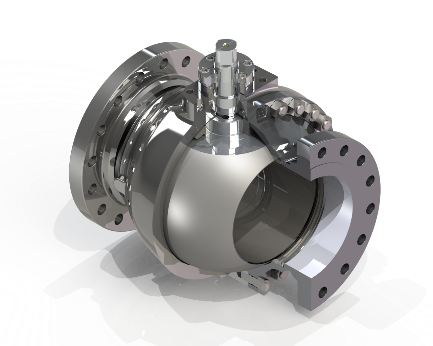

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements.

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements. -

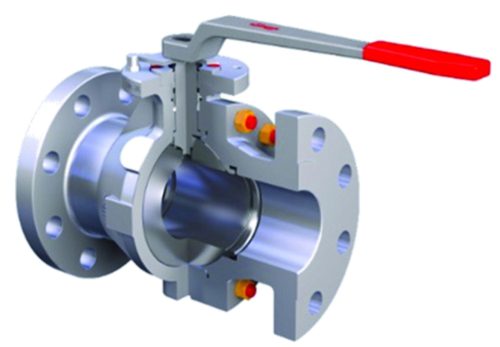

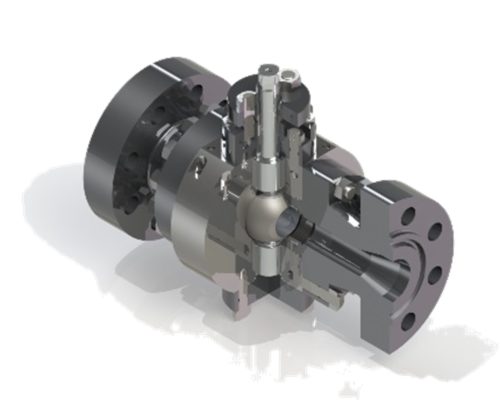

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads. -

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements.

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements. -

The FK76C split-body, full-bore, trunnion-mounted ball valve represents the highest standards in valve technology. Its superfine finished, trunnion-mounted ball design is just one of its many important design features. Among them are an anti-blow out stem,long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The FK76C split-body, full-bore, trunnion-mounted ball valve represents the highest standards in valve technology. Its superfine finished, trunnion-mounted ball design is just one of its many important design features. Among them are an anti-blow out stem,long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads. -

Argus FK76M trunnion mounted ball valves are engineered to deliver long-lasting, tight shut-off performance in oil and gas, petrochemical and chemical industry applications. It features a modular design that allows simplified adaptation to diverse safety, emissions and performance requirements. The FK76M ball valve is available in standard and severe service designs and offers metal-seated and soft-seated configurations for reliable sealing performance. Special and customized designs are also available for ultimate high cycle, high temperature and similar challenging applications. These valves are designed to meet API 6D and ASME B16.34 requirements (API 608 on request). Fugitive emission to ISO 15848 (API 641 on request). Fire-safe to API 607 or ISO 10497.

Argus FK76M trunnion mounted ball valves are engineered to deliver long-lasting, tight shut-off performance in oil and gas, petrochemical and chemical industry applications. It features a modular design that allows simplified adaptation to diverse safety, emissions and performance requirements. The FK76M ball valve is available in standard and severe service designs and offers metal-seated and soft-seated configurations for reliable sealing performance. Special and customized designs are also available for ultimate high cycle, high temperature and similar challenging applications. These valves are designed to meet API 6D and ASME B16.34 requirements (API 608 on request). Fugitive emission to ISO 15848 (API 641 on request). Fire-safe to API 607 or ISO 10497. -

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607.

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607. -

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory.

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory. -

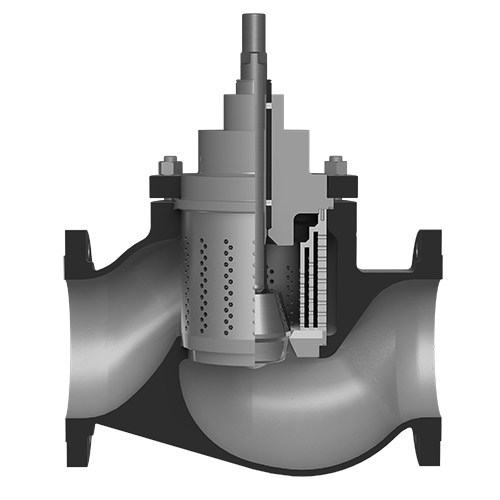

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform.

The Valtek Mark One globe control valve offers superior performance in liquid and gaseous services, while also permitting easy, fast, and inexpensive maintenance. In standard plug and seat single-stage configuration, the base design provides various design advantages over conventional cage-guided designs. With the ability to be fitted with severe service trims for cavitation, noise, and erosion applications, the Mark One is the most versatile control valve platform. -

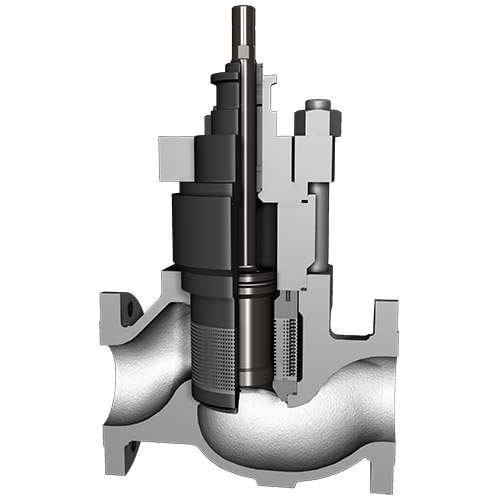

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise.

MegaStream control valve trim reduces control valve noise and vibration in a wide range of gas applications. MegaStream works to reduce noise by up to 30 dBa through staging, frequency shifting, attenuation and velocity control. With decades of proven experience, the MegaStream control valve is the one of the most common solutions to control valve noise. -

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results.

Multi-Z valves are used if solids are entrained in the medium and if there is a possibility of cavitation forming. In addition this multiple stage valve is capable of reducing high-pressure differentials via a multiple stage relief process. Flowserve reduces pressure via division in partitions, a course which is different to that pursued by other suppliers. The major advantage is a noticeable reduction in wear combined with an extremely low-noise control valve. Likewise deviating from conventional procedures, in order to avoid cavitation a physically optimized technology has been implemented that achieves significantly better results. -

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience.

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience. -

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions.

SideWinder trim prevents cavitation from forming and minimizes hydrodynamic noise in high pressure drop, low flow applications. Staged pressure drops eliminate cavitation by maintaining pressure above the vapor pressure, so that cavitation never forms. Using the proven DiamondBack advanced pressure drop mechanisms in an axial flow configuration producing precise control in low flow conditions. -

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise.

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise. -

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids.

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids. -

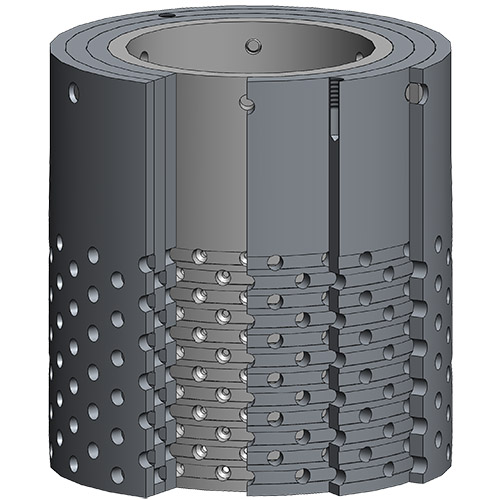

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services.

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services.