-

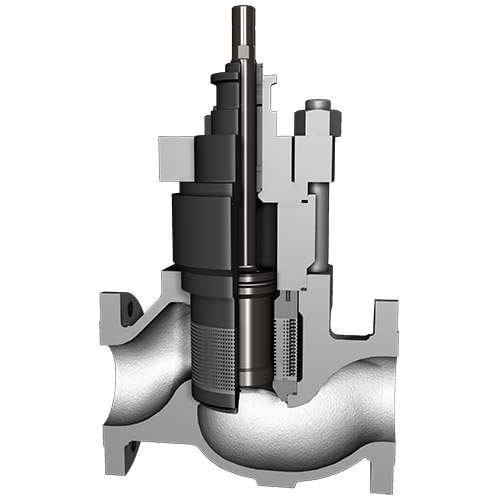

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise.

Stealth control valve trim reduces control valve noise and vibration in the most demanding gas applications. Stealth combines new advances in noise control with previously proven technologies to create the most effective device capable of eliminating noise in the most demanding services. In addition to reducing the pressure gradually, Stealth takes advantage of frequency shifting by providing small outlet holes which raise the frequency and lower the noise. -

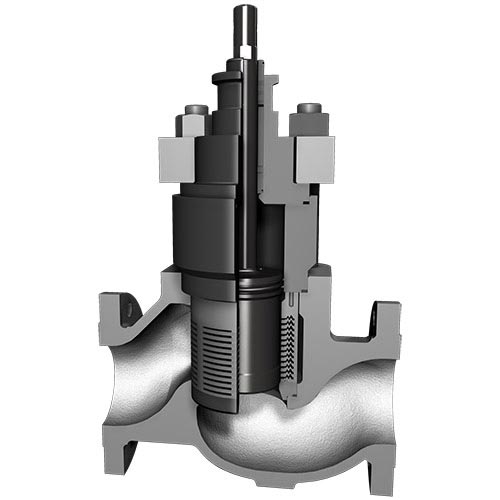

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services.

TigerTooth control valve trim creates multi-staged pressure drops that are effective in reducing noise and vibration in gas services and in eliminating cavitation in liquid services. TigerTooth effectively reduces noise and vibration in gas services by up to 35 dBa through staging, attenuation and velocity control. TigerTooth uses multi-stage pressure drops to eliminate cavitation in liquid services. -

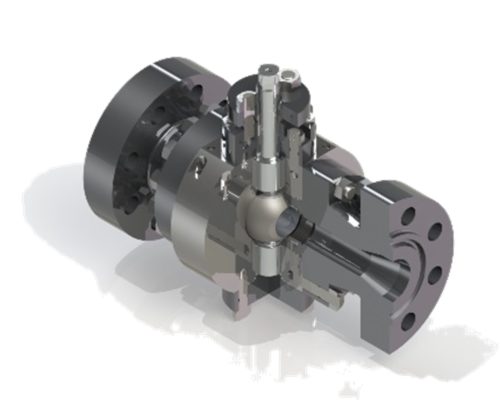

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids.

The unique Survivor control valve design solves the harshest erosion, corrosion and flashing applications. With a variety of ceramic trims available, no other valve will last longer, even in applications with demanding flashing and erosive particulate. The unique design of the Survivor directs flashing energy away from critical equipment. Unique packing configurations solve difficult sealing problems associated with solids entraining the process fluids. -

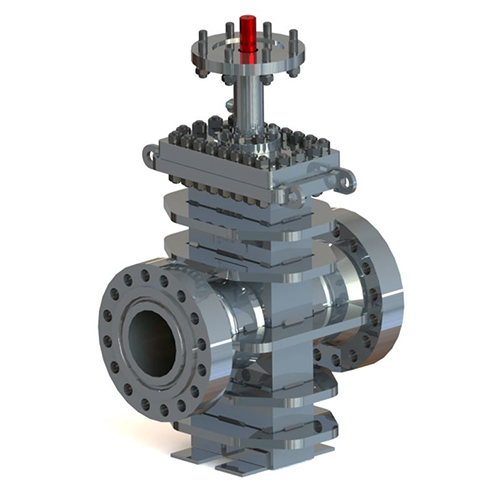

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory.

The Argus HK35 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation of the sealing and bearing functions, on both ball and stem. The Argus HK35 has all the benefits of the FK76M in a high-pressure design. It is designed to perform in severe conditions where compliance to the highest demands in tightness for leak rate and fugitive emission is mandatory. -

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief.

The Valbart Cryogenic Ball Valve meets demanding end-user requirements for leak rate and fugitive emission performance. It's body construction and flexible trim configurations ensure proper safe isolation. It is bi-directional (std) or uni-directional (upon request), side entry or top entry with fire-safe design, with an anti-static feature and automatic cavity relief. -

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators.

Double Block and Bleed Valve is a side-entry ball valve, with either a bolted or welded body, designed for use in upstream, midstream and downstream oil and gas applications. It requires two in-line isolation valves and a bleed valve used to drain or vent trapped fluid between the two closure elements in order to safely isolate the downstream pipe. This feature can be achieved with one single valves complete with a bleed port between the obturators. -

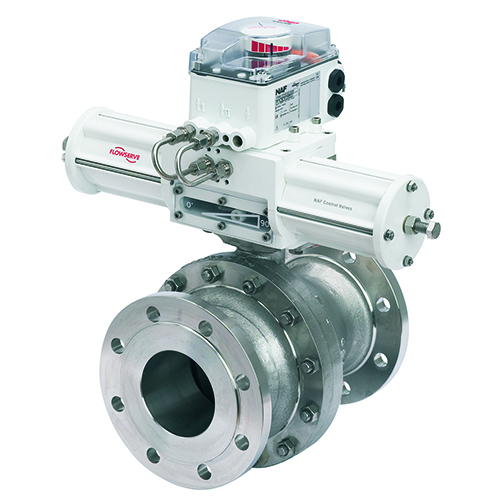

The NAF Trunnball DL is a full-bore trunnion-mounted ball valve, developed by Flowserve engineers with more than 80 years of experience manufacturing ball valves. The ball is supported by two large, low friction trunnion bearings for consistent low torque even at high differential pressures. Due to its bi-directional tightness, low friction and high controllability, it is an excellent choice for isolation, on/off and modulating control applications.

The NAF Trunnball DL is a full-bore trunnion-mounted ball valve, developed by Flowserve engineers with more than 80 years of experience manufacturing ball valves. The ball is supported by two large, low friction trunnion bearings for consistent low torque even at high differential pressures. Due to its bi-directional tightness, low friction and high controllability, it is an excellent choice for isolation, on/off and modulating control applications. -

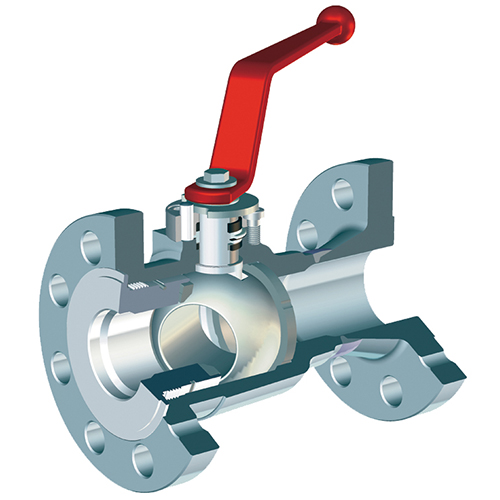

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607.

The Argus FK79 ball valve with its many innovative design features represents the highest standard in valve technology and is designed to meet the API 6D, ANSI 16.34 and BS 5351 requirements. Split body design with superfine finished seat supported ball, anti-blow-out stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements and fire-safe to BS 6755 and API 607. -

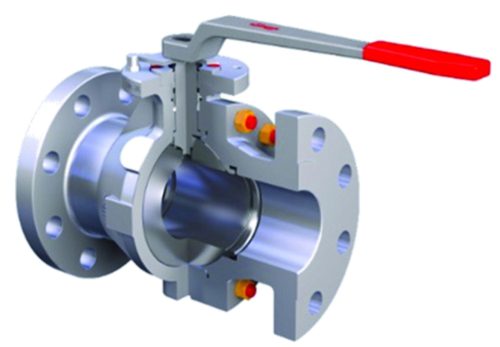

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements.

The Argus FK75M ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. Long lifetime and low operating torques due to the clear separation between the sealing and bearing functions. Split body design with superfine finished padmounted ball, anti-blow-out stem, spring loaded ball seats with cavity relief and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (method 21) fugitive emissions requirements. -

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements.

The Argus EK71 ball valve with its many innovative design features represents the highest standards in valve technology and is designed to meet the API-6D, ANSI 16.34 and BS 5351 requirements. One piece low temperature forged Carbon Steel body design (end entry) with superfine finished seat supported ball, anti-blowout stem, compact ball seats and anti-static device. Long life double stem seal system and stem supported in bearings to ensure seals are free from operating loads. Stem sealing construction complies with the latest TA-Luft and EPA (Method 21) fugitive emissions requirements. -

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads.

The Argus FK75C split-body, full-bore, floating ball valve represents the highest standards in valve technology. Its superfine-finished, seat-supported ball is just one of its many important design features. Others include an anti-blow out stem, long-life, double-stem seal system and stem supported in bearings to ensure seals are free from operation loads. -

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance.

The Duball DL is a high-performance, metal-seated, full-bore ball valve, equally suitable for isolation, on-off and modulating control applications. The excellent characteristics of NAF Duball DL are particularly beneficial under the most challenging operating conditions in the process industry, where difficult media and demanding pressure conditions make severe demands on the design, materials and performance. -

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience.

The Valbart Rising Stem Ball Valve (RSBV) is the oil and gas industry's choice for applications requiring a mechanically energized metal seat or soft-seat to safeguard against losses from process contamination or leakage of material. Whether your needs call for molecular sieve switching, isomerization, thermal oil, high/low temperatures or critical services, the RSBV provides an unmatched level of robustness, reliability, and convenience. -

The NAF Duball DL Pocket Valve is the pulp and paper industry's choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated.

The NAF Duball DL Pocket Valve is the pulp and paper industry's choice for a reliable and robust valve solution that allows for safe removal of sand or debris in separator and junk trap applications during normal process operation. Building on years of experience in providing flow control solutions in harsh environments, the Duball DL Pocket Valve is specifically designed to ensure continuous process uptime and throughput by allowing process pressure to be maintained while unwanted process particles are eliminated. -

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications.

The NAF Duball DL Ceramic is a ball valve that is internally lined with ceramic for erosive and abrasive media. It is primarily intended for control but has a sealing class as for a shut-off valve. The valve represents a concrete result of our product philosophy which is focused on functionality, high quality and low life cycle costs, and is based on concentrating our range to a limited number of valve types, but all of them suitable for a wide variety of applications. -

The Valbart TCSGV through conduit slab gate valve is the oil and gas industry's choice for liquid and gas applications requiring reliable, tight shut-off to prevent leakage and minimize losses from process contamination. It is ideal for pipeline applications requiring pigging capability. Its full-bore design features spring-energized seats and a floating slab gate to ensure both low- and high-pressure sealing capabilities. The Valbart TCSGV is manufactured and tested in accordance with API 6D, latest edition. Its design is fully compliant to ASME Section VIII, Division 1. Its design meets API 6D isolation features of block and bleed, double isolation bleed (DIB), double block and bleed, cavity relief, and other requirements commonly specified in the pipeline industry.

The Valbart TCSGV through conduit slab gate valve is the oil and gas industry's choice for liquid and gas applications requiring reliable, tight shut-off to prevent leakage and minimize losses from process contamination. It is ideal for pipeline applications requiring pigging capability. Its full-bore design features spring-energized seats and a floating slab gate to ensure both low- and high-pressure sealing capabilities. The Valbart TCSGV is manufactured and tested in accordance with API 6D, latest edition. Its design is fully compliant to ASME Section VIII, Division 1. Its design meets API 6D isolation features of block and bleed, double isolation bleed (DIB), double block and bleed, cavity relief, and other requirements commonly specified in the pipeline industry. -

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction.

The Valbart CEGV compact expanding gate valve is a fabricated body-expanding gate valve manufactured andtested in accordance with API 6D, latest edition. The compact expanding gate design features a full-bore diameter, with a compact, non-through conduit design providing a compact and lightweight valve package. Valbart expanding gate valves are engineered to achieve tight shutoff at high and/or low pressures in liquid or gas services. The expanding gate and segment design provides a high-integrity seal for a variety of critical applications, while affording lower operating friction. -

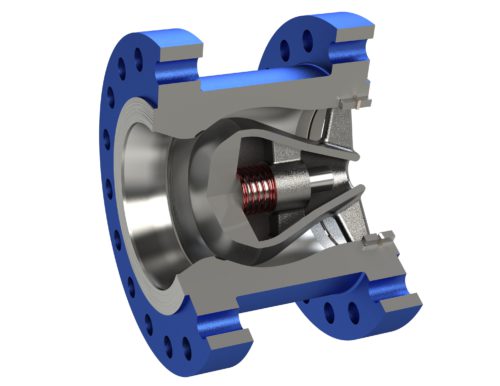

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD)

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. It is also available with the API 6D face-to-face dimensions (Series ZD) -

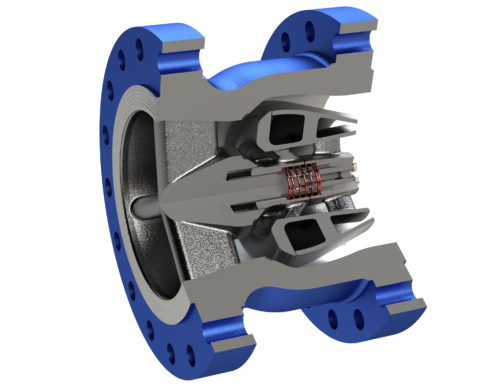

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together.

Noreva's NC is a lower cost solution which combines the advantages of the NZ with a shorter face-to-face length and reduced weight, where marginally higher pressure drops are acceptable. The NC is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NC is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. -

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. -

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses.

Designed specifically for potable water applications. The axial design allows for a streamlined flow path around the disc and high pressure recovery, minimising pressure drop across the valve. The efficient design combined with the highly responsive non-slam operation make this valve ideal for high head, critical pump applications. Its optimum designed aerodynamic flow path through the valve results in very low pressure losses. -

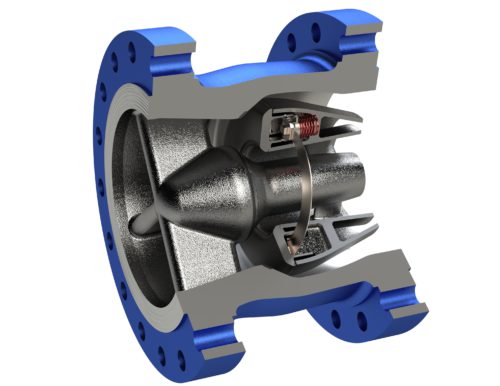

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND)

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. It is also available with the API 6D face-to-face dimensions (Series ND) -

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The NK type, with its reduced body length and its consequent reduced weight, offesr significant cost savings compared with the long pattern NB and ND types. The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. -

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance.

The unique ring disc design ensures that the disc remains light and responsive even in large sizes, which is essential for rapid non-slam closure. Mounted on a multiple spring and radial guide assembly, the disc moves freely without the frictional forces. Combining two ring-shaped annular flow paths with the excellent pressure recovery properties provided by the diffuser, the minimal pressure drop across the Type N valves gives lifetime energy savings when compared to more conventional check valve designs. Pressure recovery is further enhanced within the NG series due to a wider split-body design to facilitate greater flow efficiency and throughput performance. -

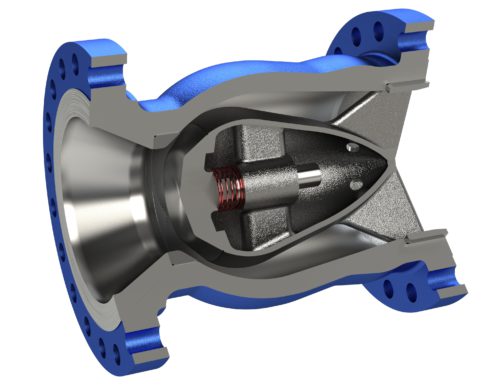

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NZ is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NZ is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss.

Noreva's NA is specially designed for gas applications having a centrally guided, single spring with very low fully open velocity. The design is focused on laying the centre of gravity of the only moving part, the disc, over the centre of the surface it is sliding on. Due to this design change, the NA is able to use softer springs, which function at very low flow rates, mainly because the tilting effect of the moving component is eliminated all together. It provides the same internal flow profiles and consequentally, the same pressure loss. -

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow.

The Valtek Mark Four Tek-Check, non-slamming piston check valve, provides rugged performance and reliable service in corrosive and non-corrosive, gas and liquid applications. The smooth, nearly-constant area internal passages allow for high capacity flow with minimum turbulence. When the flow ceases or is reversed, the piston closes slowly, preventing pressure surges. The non-slam design is also effective in dampening pulsating flow. -

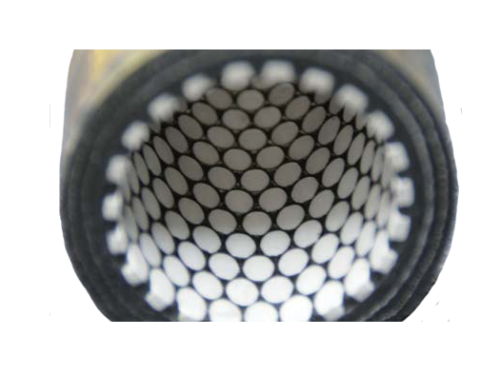

Ceresist ceramic lined pipe spools are designed to outlast linings such as glass, rubber, basalt, hard facings, coatings, trowelable linings, cure-in-place linings, and plastics that are commonly used to extend the life of piping systems. These materials are only a fraction of the hardness and wear resistance of our ceramics, and in the presence of corrosion or high temperatures, most linings become severely incompatible and their use is extremely limited

Ceresist ceramic lined pipe spools are designed to outlast linings such as glass, rubber, basalt, hard facings, coatings, trowelable linings, cure-in-place linings, and plastics that are commonly used to extend the life of piping systems. These materials are only a fraction of the hardness and wear resistance of our ceramics, and in the presence of corrosion or high temperatures, most linings become severely incompatible and their use is extremely limited -

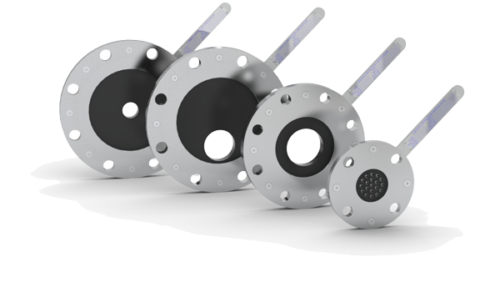

Ceresist ceramic-lined chokes are specified for use in extremely erosive slurries that contain a very high percentage of solids. The large radius entry of the chokes exhibit better consistency and flow recovery characteristics than sharp-edged orifice plates. Furthermore, our ceramic-lined chokes are more compact than venturi-style chokes. The silicon carbide ceramic choke insert is 30 times more wear-resistant than stainless steel, and offers years of maintenance-free service.

Ceresist ceramic-lined chokes are specified for use in extremely erosive slurries that contain a very high percentage of solids. The large radius entry of the chokes exhibit better consistency and flow recovery characteristics than sharp-edged orifice plates. Furthermore, our ceramic-lined chokes are more compact than venturi-style chokes. The silicon carbide ceramic choke insert is 30 times more wear-resistant than stainless steel, and offers years of maintenance-free service. -

Ceresist's CER-1200 fine-grain alumina ceramic is next to diamond in hardness and outlasts steel by 12 times and Ni-hard by 5 times. Ceresist wear-resistant products are a long-term, maintenance-free solution in systems that experience rapid degradation due to sliding abrasion, erosion, and impact - even in highly corrosive or high-temperature services.

Ceresist's CER-1200 fine-grain alumina ceramic is next to diamond in hardness and outlasts steel by 12 times and Ni-hard by 5 times. Ceresist wear-resistant products are a long-term, maintenance-free solution in systems that experience rapid degradation due to sliding abrasion, erosion, and impact - even in highly corrosive or high-temperature services. -

Ceresist CeramFlex™ Series ceramic-lined flexible hoses are ideal for use in highly aggressive services where conventional unlined rubber hoses require frequent replacement. CeramFlex™ hoses may also be used to isolate mechanical vibration or to connect non-stationary equipment. Eliminate unscheduled shut-downs, increase production throughput, and increase profits.

Ceresist CeramFlex™ Series ceramic-lined flexible hoses are ideal for use in highly aggressive services where conventional unlined rubber hoses require frequent replacement. CeramFlex™ hoses may also be used to isolate mechanical vibration or to connect non-stationary equipment. Eliminate unscheduled shut-downs, increase production throughput, and increase profits. -

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs.

The Flowserve Logix 3800e positioner is a value-based robust digital positioner engineered for unmatched performance for valve control and monitoring. Built on the same platform as the proven design of the Logix 3800 digital positioner from Flowserve, the Logix 3800e positioner is a cost-competitive, easy-to-use, high-precision unit that facilitates improvements in process uptime and yield at low costs.